A multi-plane collimated energy-dissipating shock absorber

A collimation and shock absorber technology, which is applied in the direction of shock resistance and building components, can solve the problems of shock absorption effect, self-heaviness, deformation instability, etc., and achieve the effect of wide application range, strong absorption capacity and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

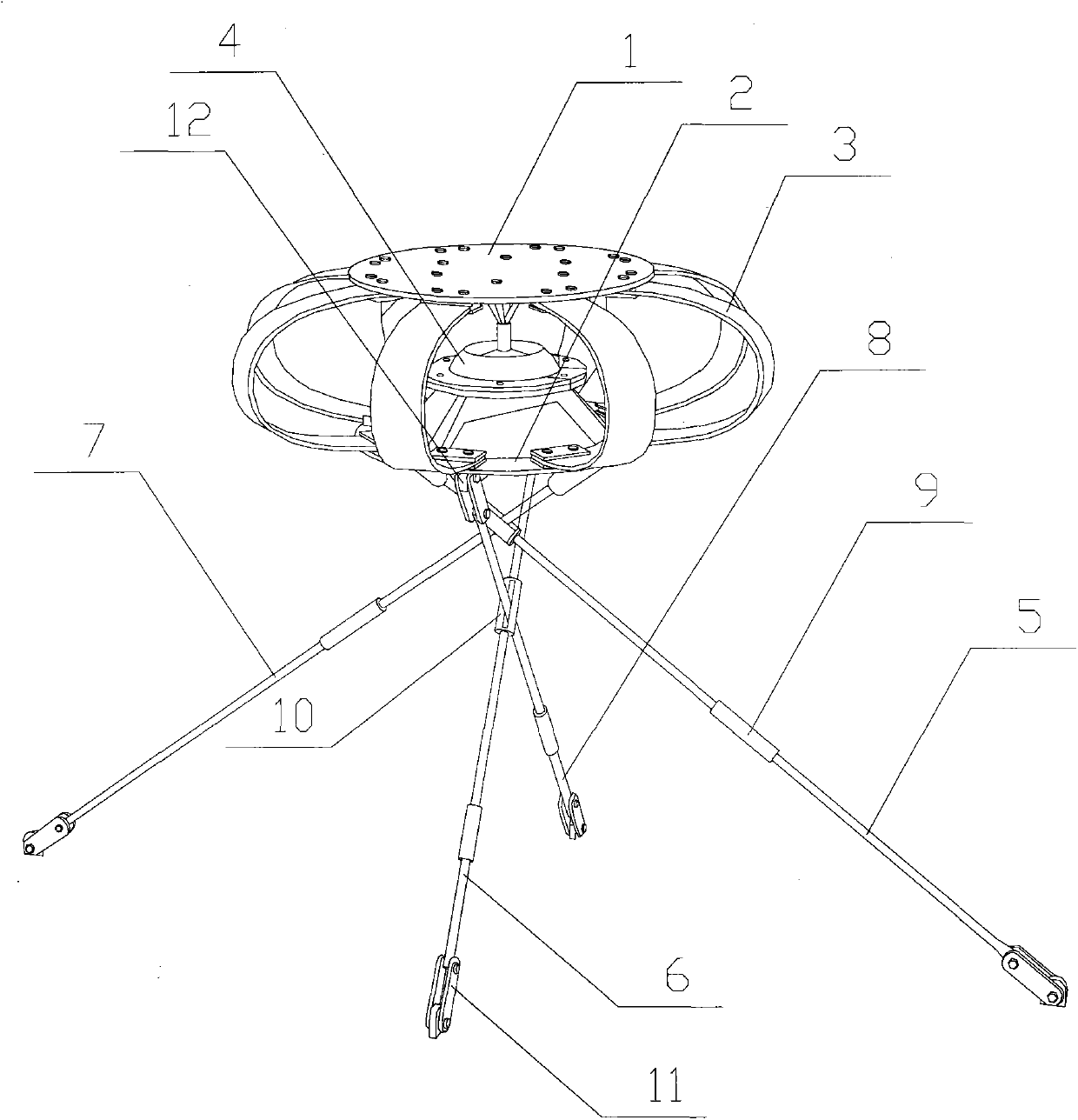

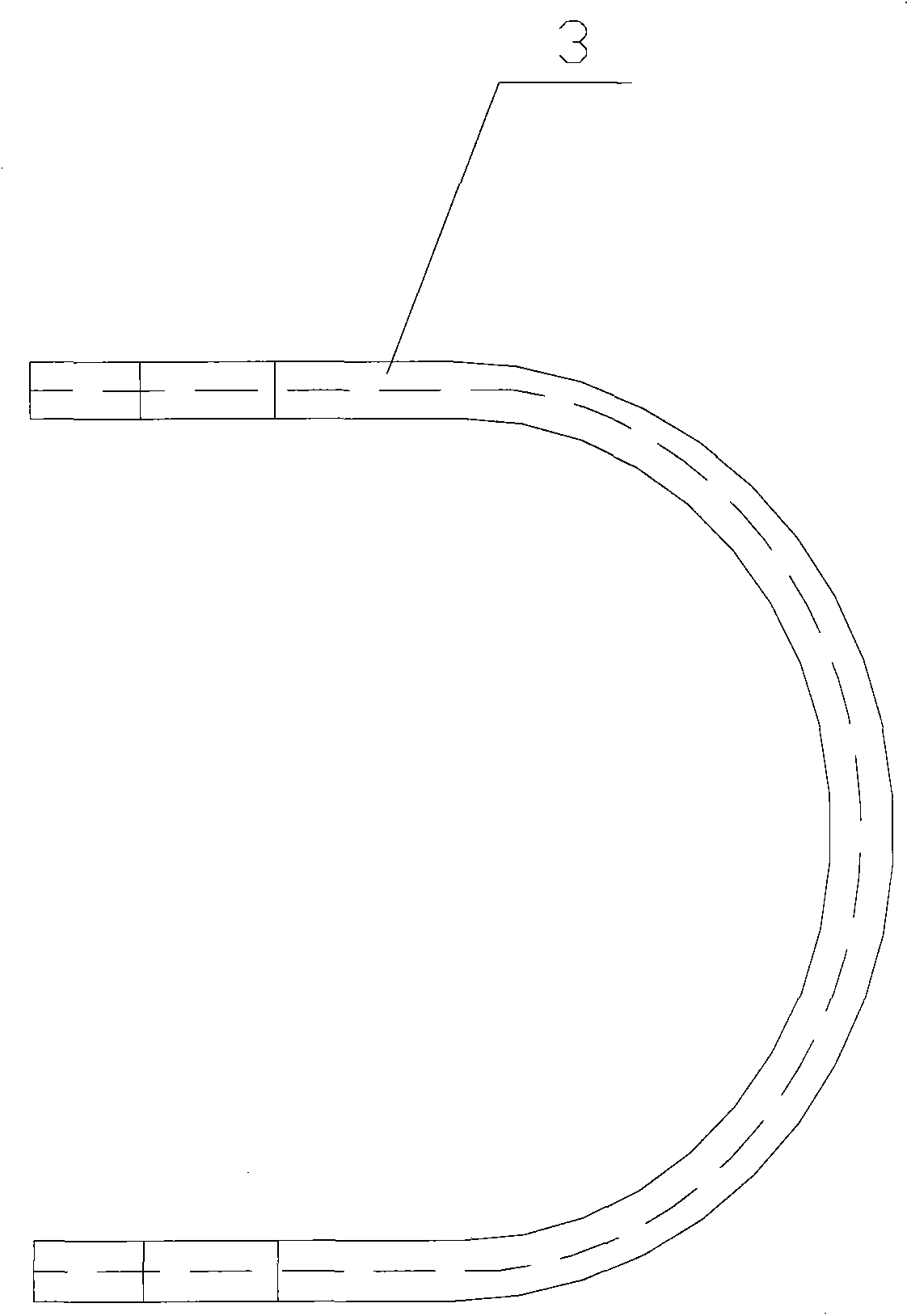

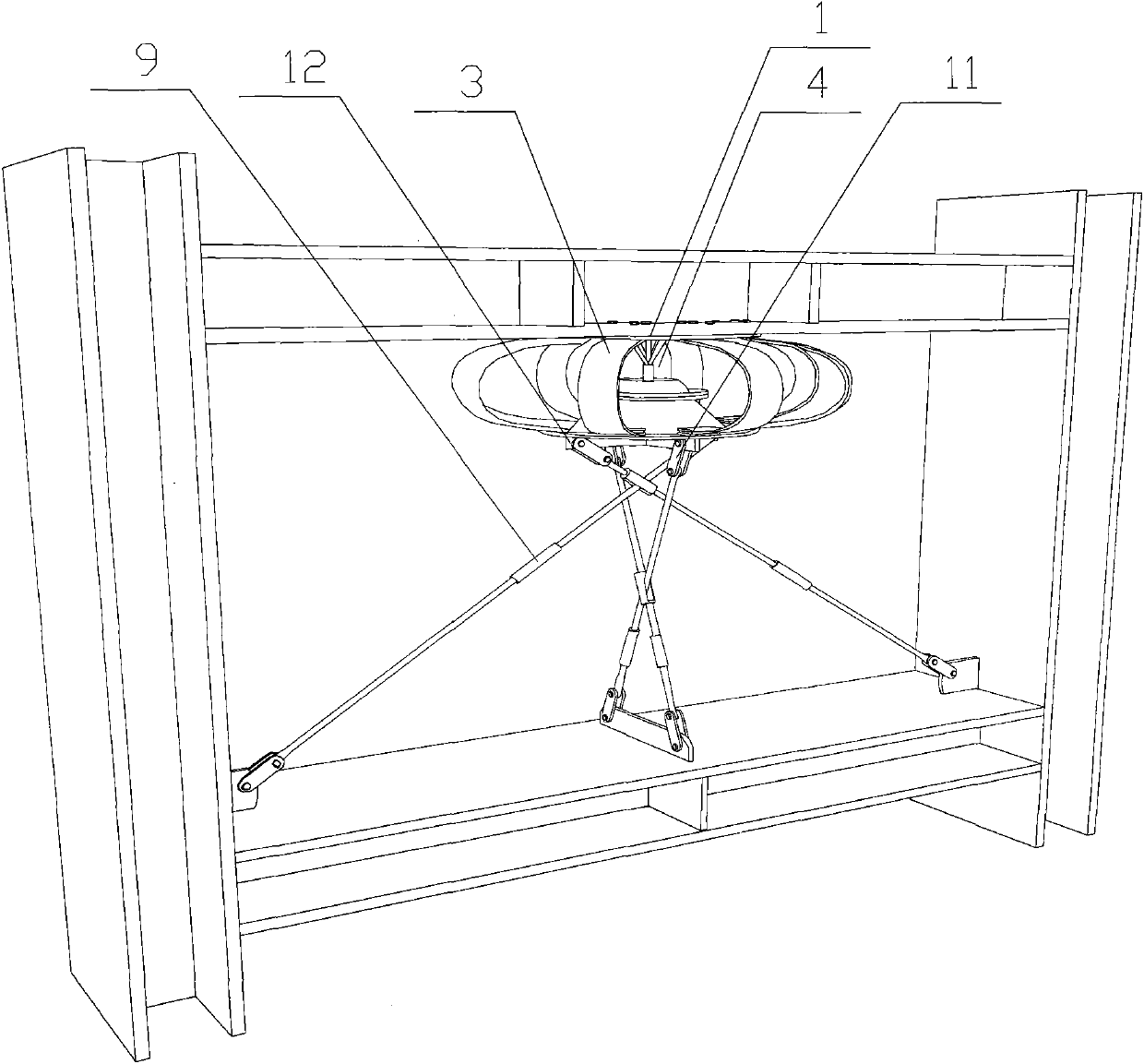

[0012] Such as Figure 1-Figure 3 As shown, the specific embodiment adopts the following technical scheme: it includes upper steel plate 1, lower steel plate 2, U-shaped steel plate energy dissipation damping 3, ball hinge 4, first steel round bar 5, second steel round bar 6, third Steel round bar 7, fourth steel round bar 8, steel cylinder with internal thread 9, hollow steel round bar 10, hinged steel plate 11, stiffening rib 12, upper steel plate 1 and lower steel plate 2 are connected by ball hinge 4 to form a rotating fixture , several U-shaped steel plate energy dissipation dampers 3 are evenly distributed in the fixture, the upper part of the lower steel plate 2 is provided with a hinge member, the lower part of the lower steel plate 2 is provided with a stiffener 12, the first steel round bar 5, the second steel round bar 6 , the third steel round bar 7 and the fourth steel round bar 8 are intersected, wherein the intersection of the second steel round bar 6 and the fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com