Anti-splash and anti-adhesion type process cavity of TRACK machine glue evening unit

A process cavity and anti-adhesion technology, applied in the field of process cavity, can solve the problems of photoresist adhesion and backsplash, and achieve the effect of reducing adhesion, improving performance and reducing the number of particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

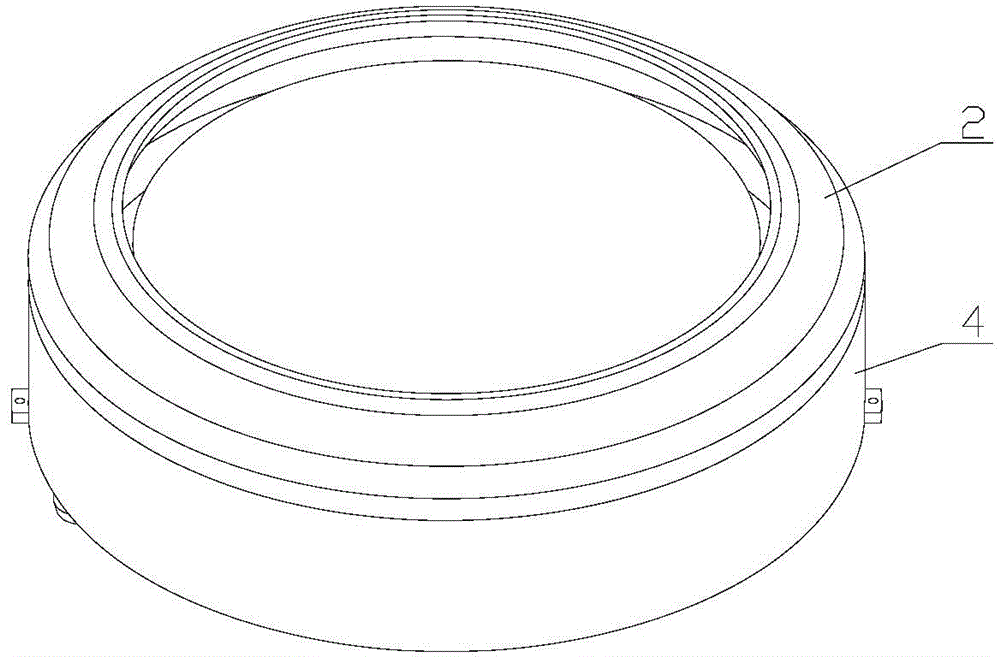

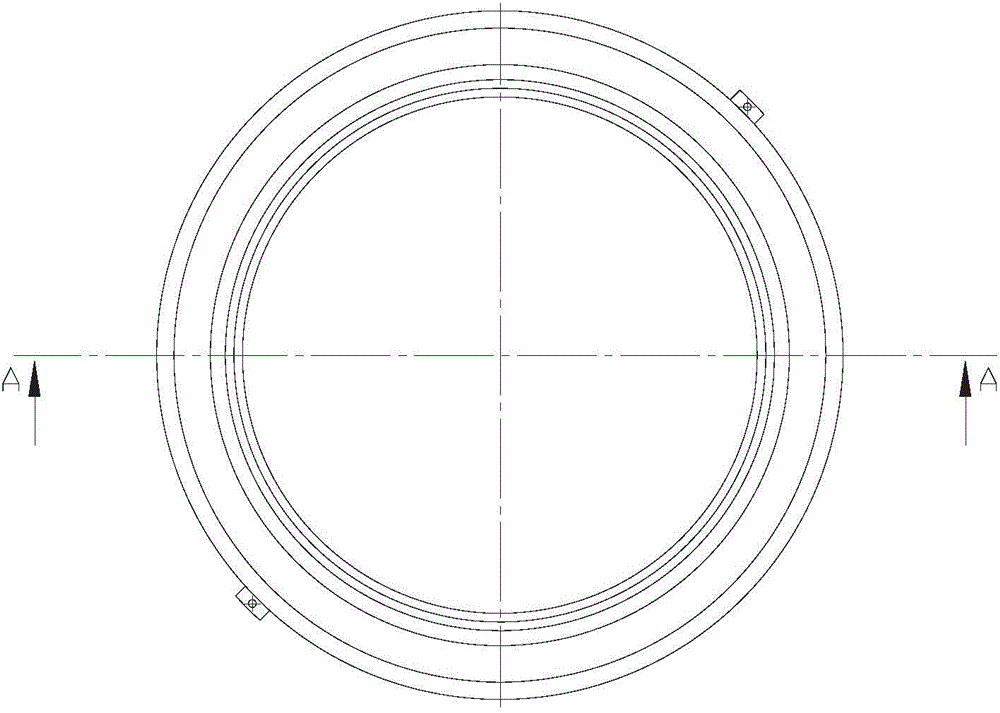

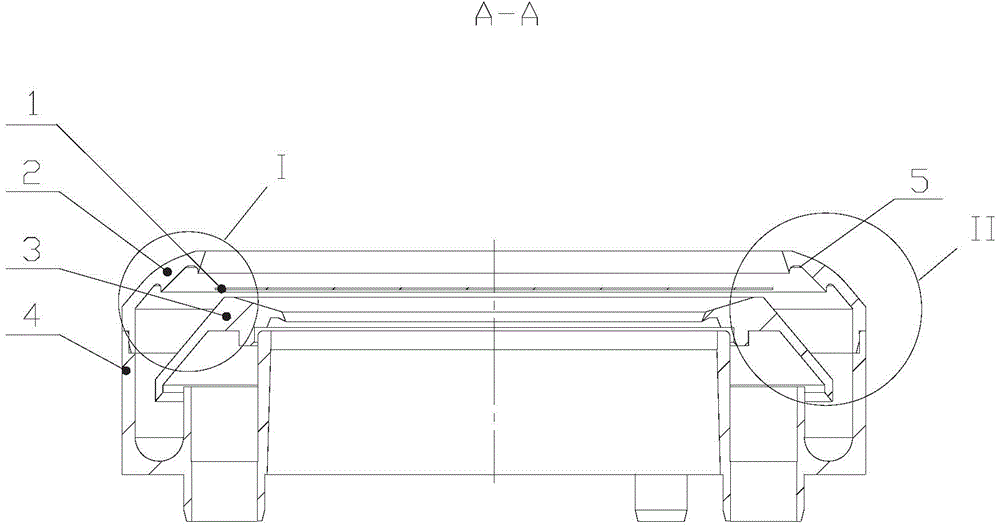

[0020] Such as Figure 1-3 As shown, the present invention includes an upper process chamber 2, a middle process chamber 3 and a lower process chamber 4, and the upper process chamber 2 and the middle process chamber 3 cooperate with the lower process chamber 4 respectively to form a whole. The upper process chamber inner surface 10 of the upper process chamber 2 is provided with an anti-splash groove 5 and coated with a hydrophilic layer.

[0021] Such as Figure 4 As shown, the anti-backlash tank 5 includes an upper back-splash tank and a lower back-splash tank, and the upper back-splash tank and the lower back-splash tank are along the upper process chamber inner surface 10 The grooves are concave upwards from top to bottom, and the wafer 1 is located between the lower edge 6 of the upper anti-splash groove and the lower edge 8 of the lower anti-splash groove. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com