Inverted laminating clamp magnetizer generator

A technology of generators and magnetizers, applied to synchronous motors with stationary armatures and rotating magnets, etc., can solve the problems of affecting input power, burning generators, and restricting the driving force of generators, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

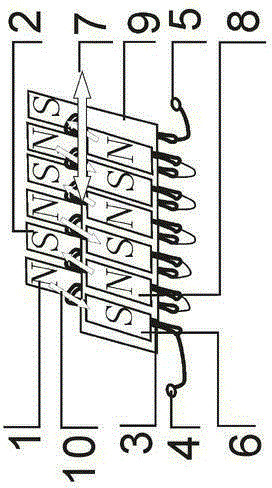

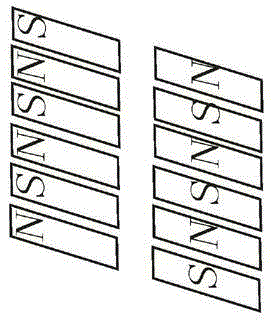

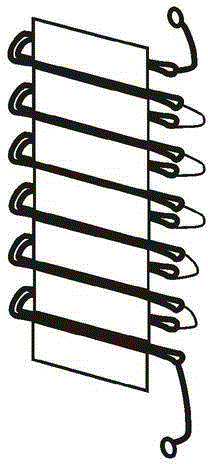

[0018] The generator structure of the present invention includes: 1 magnetic field N pole and 2 magnetic field S pole and 8 magnetic field N pole and 6 magnetic field S pole to cut the magnetic field rotor; 3 reverse stacked card wire packages form the generator stator; 1 magnetic field N pole and 2 Magnetic field S poles and 8 magnetic field N poles 6 Magnetic field S poles Cutting magnetic field The rotor is relative to the 3 anti-stacked stacked wire packs to form the generator stator for cutting movement 4 and 5 The output ports of the wire packs generate induced voltages respectively, and the 3 anti-stacked stacked card conductors The magnetic induction forms a non-closed loop, forming no magnetic resistance relative to the rotor.

[0019] The present invention consists of 1 magnetic field N pole, 2 magnetic field S poles, 8 magnetic field N poles, 9 magnetic field S poles, and 3 anti-stacked stacked wire wraps to form a magnetic induction electric cutting magnetic field.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com