Plastic injection mold ejector pin reset mechanism

A technology of reset mechanism and injection mold, which is applied in the field of reset device, and can solve the problems that the agreement is difficult to restore the reset position, broken, and the thimble plate cannot be reset, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

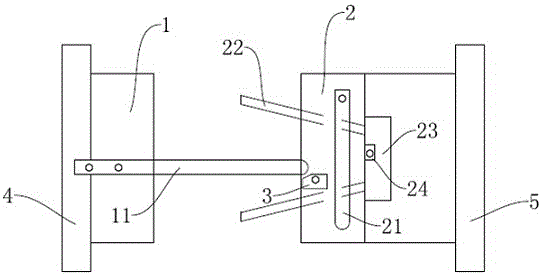

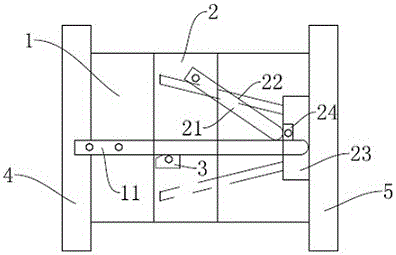

[0013] The thimble reset mechanism of the injection mold of the present invention, the thimble reset of the traditional injection mold is by adding a spring between the thimble plate 23 and the movable mold 2, and the piston rod of the cylinder is connected to the movable template 2, and the cylinder is fixed on the movable mold frame 5. Fixed mold 1 and movable mold 2, during the mold closing process, the ejector pin plate 23 is used to reset the ejector pin of the injection mold after mold closing by the spring, such as figure 1 As shown, the movable mold 1 is fixed on the fixed mold frame 3, the movable mold 2 is fixed on the movable mold frame 4, the upper and lower inclined roofs 22 in the movable mold 2 are fixed on the ejector plate 23, and the ejector plate 23 is connected with a fixed block 24 , the power rod 11 is horizontally fixed on the fixed mold 1 by two bolts, the power rod 11 extends horizontally to the right and contacts the fixed block 24, and the movable mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com