Cage part for a rolling bearing cage

A technology of rolling bearings and cages, applied in the direction of bearing components, rotating parts that resist centrifugal force, bearings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

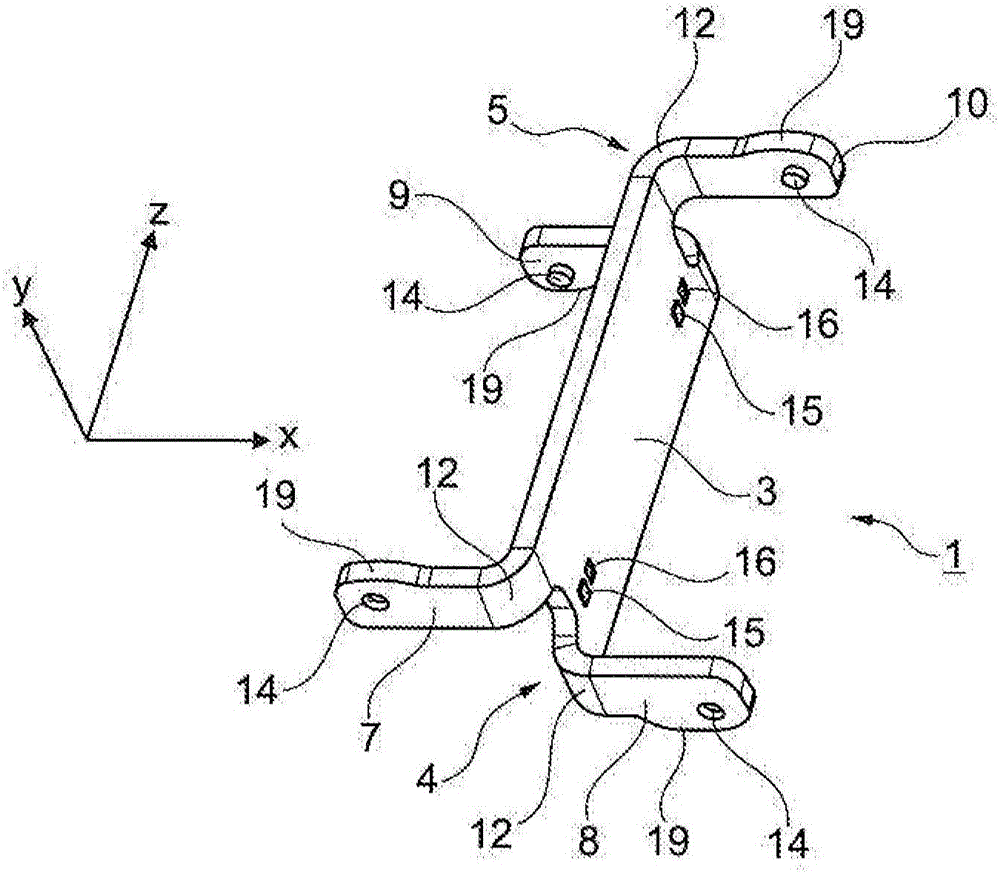

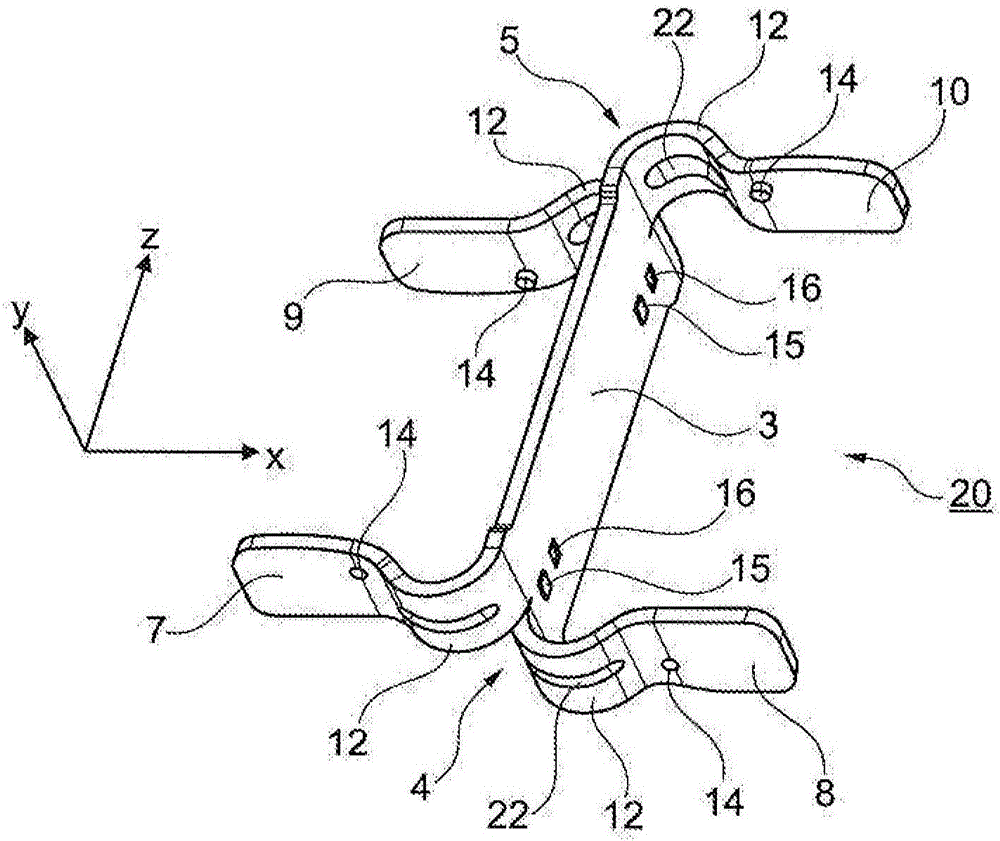

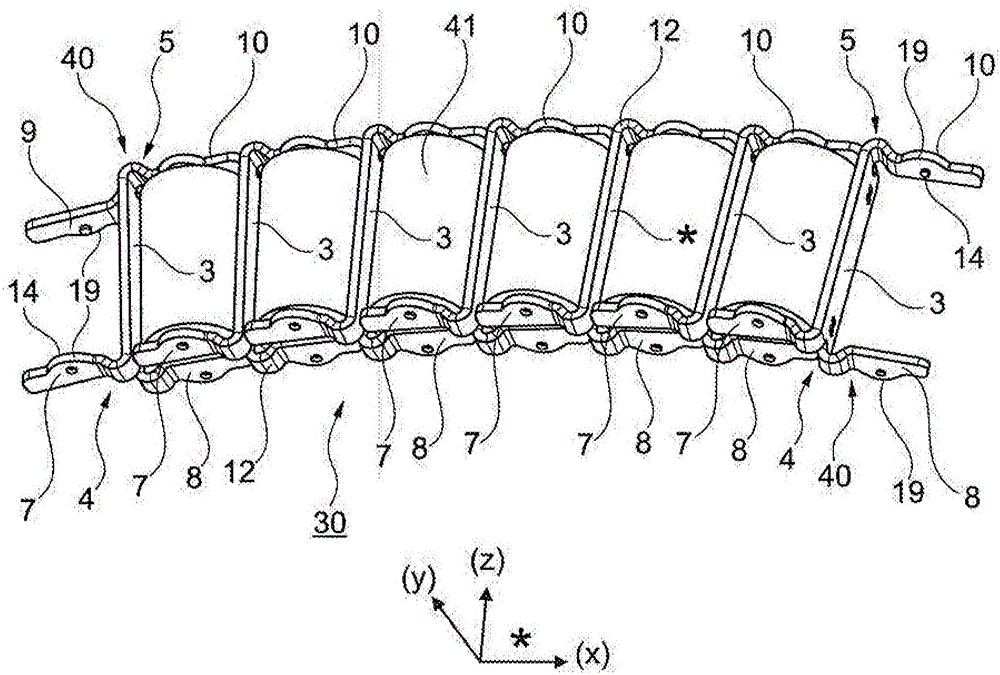

[0027] figure 1 The cage part 1 for a rolling bearing cage is shown in perspective. The illustrated cage part 1 is made of a sheet metal strip and comprises a web 3 extending in the longitudinal direction Z, at the ends of which a first support arm 4 and a second support arm 5 are arranged. The two support arms 4 , 5 each extend in a first transverse direction X perpendicular to the longitudinal direction Z and each comprise two half arms 7 , 8 or 9 , 10 bent opposite each other from the web 3 , which are are offset from each other in a second transverse direction Y perpendicular to the first transverse direction X and perpendicular to the longitudinal direction Z. The illustrated cage part 1 has an essentially H-shape. The half-arms 7 , 8 , 9 , 10 are produced by opposite bending of the separated ends of the metal strip.

[0028] The half-arms 7 , 9 and 8 , 10 of the opposite side arm 4 or 5 extending in the same direction are likewise offset from one another in the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com