An improved automatic cleaning and maintenance device for bridges

An automatic cleaning and maintenance device technology, applied in bridge maintenance, bridges, bridge reinforcement, etc., can solve the problems of easy accumulation of dust and other dirt in local connection positions, the risk of bridge structure safety and stability, and the complex structure of connecting parts, etc. To achieve the effect of stable force, excessive compression protection, and weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Combine below Figure 1-4 The present invention will be described in detail.

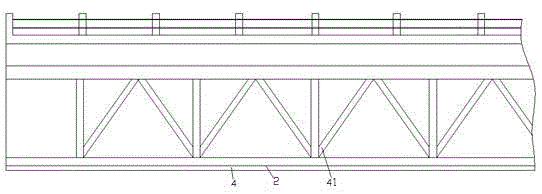

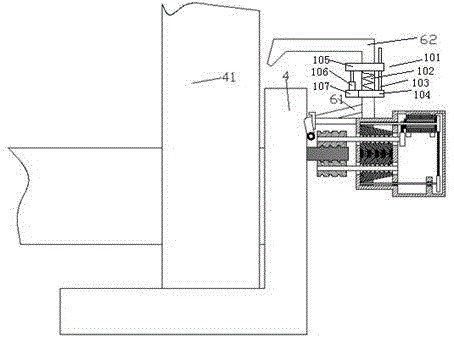

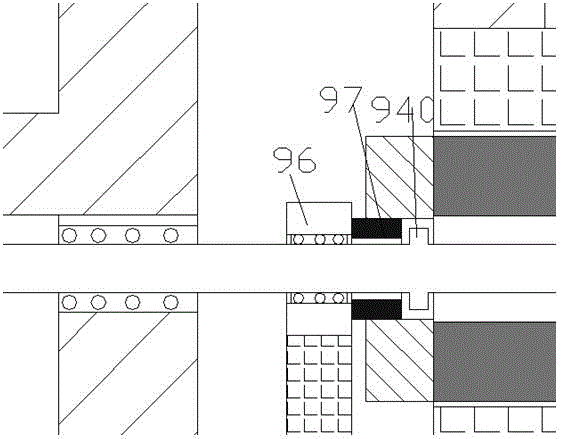

[0012] According to the improved automatic cleaning and maintenance device for bridges in the embodiment, the bridge includes a transverse main beam 4 provided with laterally extending guide ribs 2 and an auxiliary beam 41 supported on the transverse main beam 4, the automatic cleaning and maintenance device Including a support frame 99, a water supply pipe 61 supported on the support frame 99 and close to the transverse girder 4, and a nozzle 62 communicated with the water supply pipe 61 so as to aim at the parts of the bridge that need to be cleaned for spray cleaning, The upper and lower surfaces of the guide rib 2 are respectively provided with a plurality of guide protrusions extending along the guide rib 2, so as to be able to engage with the upper supporting rollers 921 of the automatic cleaning and maintenance device respectively on the upper and lower surfaces. Cooperate with the ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com