Capsule trolley jacking device

A jacking device and jacking technology, which is applied in construction, infrastructure engineering, caissons, etc., can solve problems such as difficulty in ensuring the flatness of the bottom surface of the cover plate, affecting the reliability of the caisson, and uneven force on the trolley, so as to improve the elasticity , improve the service life and ensure the effect of internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

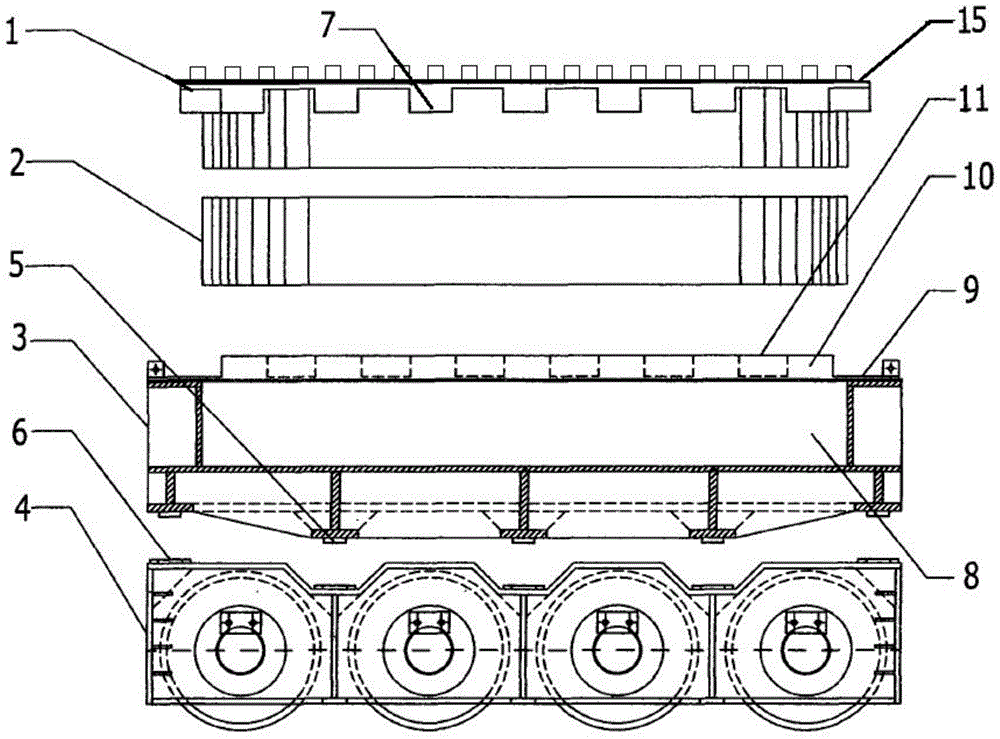

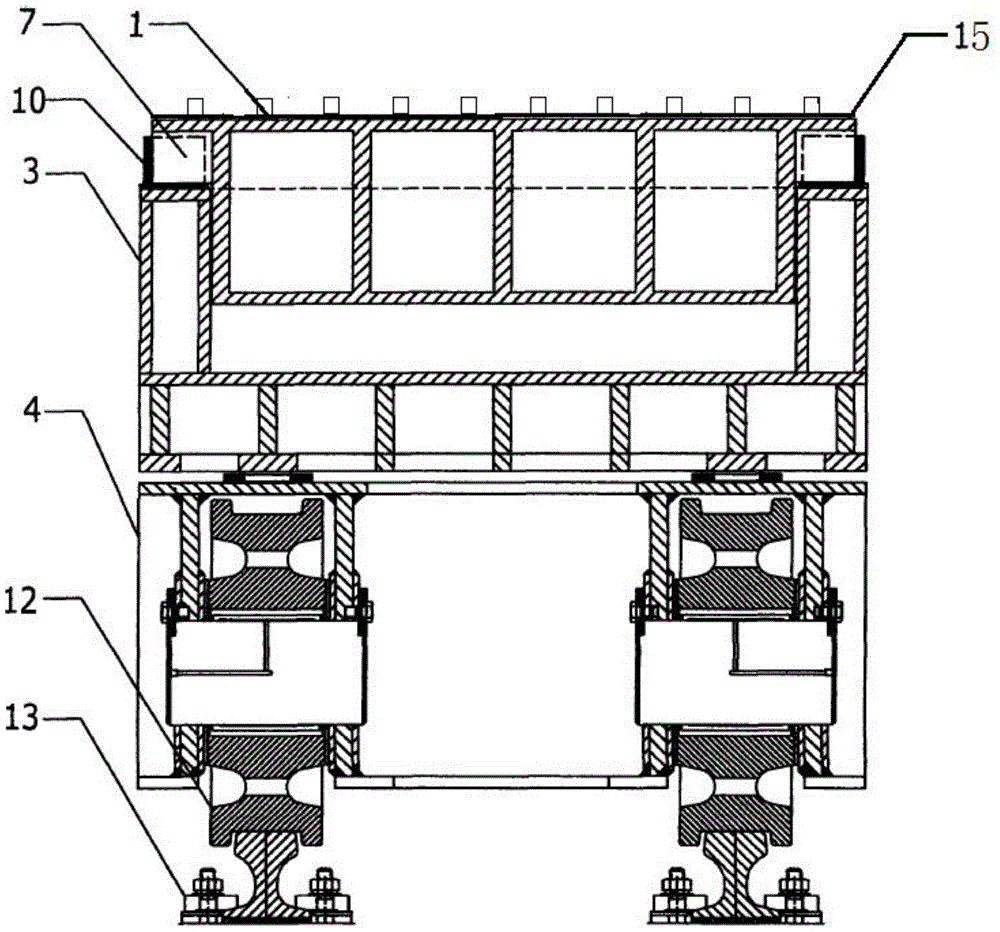

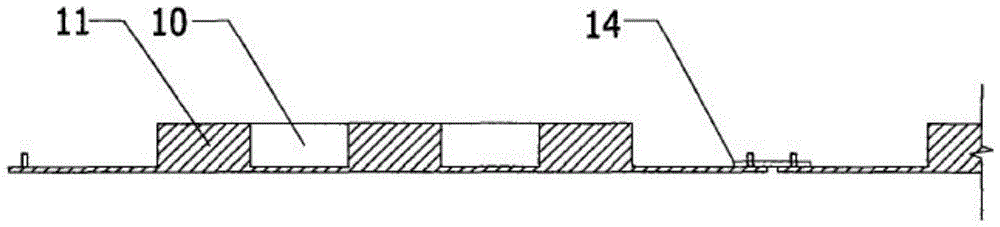

[0029] The invention discloses a capsule trolley jacking device, see Figure 1-Figure 3 , the jacking device is composed of a plurality of trolley units, and each trolley unit includes a base frame 4, a jacking support box 3, a jacking capsule 2 and a caisson lifting plate 1.

[0030] The base frame 4 is installed on the track 13 through the wheel rail 12, the jacking support box 3 is installed on the base frame 4, the jacking capsule 2 is arranged in the box, and the caisson lifting plate 1 is installed on the jacking support box 3 The top can be lifted by the jacking capsule 2, and the jacking support box 3 is provided with a pipeline, and the pipeline is connected with the nozzle of the jacking capsule 2.

[0031] The upper surface of the base frame 4 is provided with a groove with a trapezoidal cross-section, and the surface of the groove is provided with a ring-shaped embedded hole 6, and a protrusion matching the groove is provided on the lower surface of the jacking sup...

Embodiment 2

[0049] The structural composition of the capsule trolley jacking device of embodiment 2 is basically the same as that of the capsule trolley jacking device of embodiment 1, and the distinguishing features are:

[0050] The length of the multi-columnar force-regulating rubber pad is 1.2m, the width is 2.4m, and the thickness is 50mm. The number of cylindrical rubber bodies is 200. The cylindrical rubber body base adopts a cylindrical structure with a diameter of 100mm. The number of layers of the inner rib spiral structure is 5 layers, and the number of layers of the outer rib ring structure is 5 layers.

[0051] Table 1 shows the compression amount of the backing plate of the prior art and the backing plate of the present invention when the same pressure value is applied.

[0052] Table 1 The compression amount of existing backing plate and backing plate of the present invention

[0053]

Pressure value 280t

Ultimate pressure value 560t

Existing backing...

Embodiment 3

[0057] The structural composition of the capsule trolley jacking device of embodiment 3 is basically the same as that of the capsule trolley jacking device of embodiment 1, and the distinguishing features are:

[0058] The thickness of the steel backing plate 18 laid in blocks on both sides below the rail 17 is 20 mm. The steel backing plate 18 is provided with height-adjusting bolts 19 to adjust the elevation to improve the installation accuracy and ensure that the elevation deviation of the steel rail 17 of the same section is controlled within 2 mm. The height difference range within any 30 meters of the rail axis is controlled within 5mm.

[0059] Between the rail 17 and the steel backing plate 18, the thickness of the track rubber backing plate 20 is 7 mm, and the leveling height difference between the rail 17 and the steel backing plate 18 is 3 mm, which can make up for the difference between the rail and the supporting surface. The height difference ensures the balance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com