Camera module performance test method

A camera module and testing method technology, applied in the testing of mechanical parts, the testing of machine/structural parts, and the measurement of electricity, etc., can solve problems such as performance that affects use, local abnormalities or failures, and inconvenience for users to work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention.

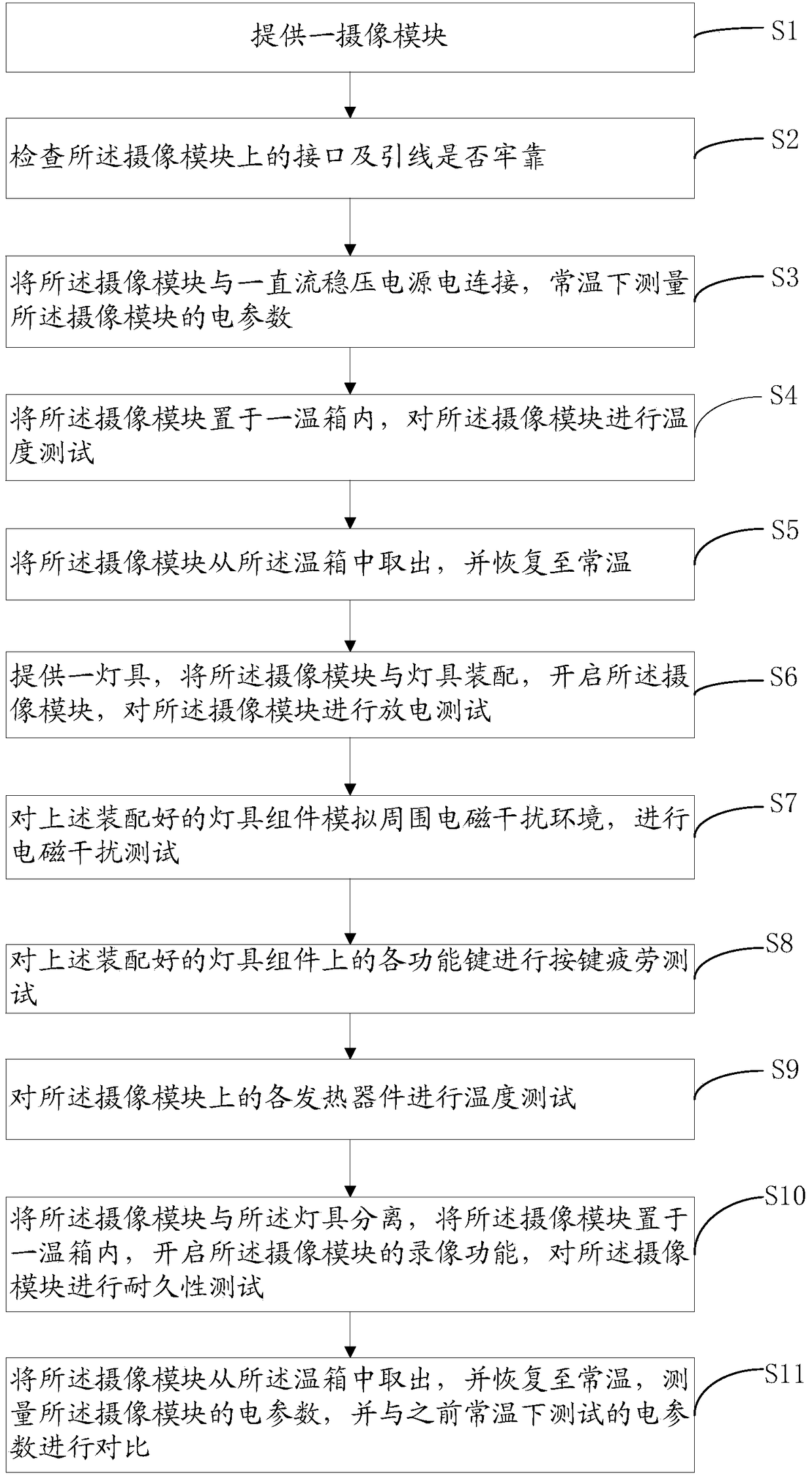

[0050] see figure 1 , a method for testing the performance of a camera module provided by an embodiment of the present invention. The method includes the following steps:

[0051] Step S1: Provide a camera module.

[0052] Step S2: Check whether the interfaces and leads on the camera module are reliable. That is, check the abnormality of the interface, lead wire, and the welding of each electronic device on the camera module, to avoid the bad situation of the camera module when it leaves the factory, to prevent the misjudgment of the results during the test, and to ensure the accuracy and reliability of the test. This step can be checked visually in brightly lit environments. In addition, the size of the camera module can also be measured by a vernier caliper, so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com