An automatic vacuum reclaiming device

A kind of material taking device and vacuum technology, applied in the direction of distribution device, special distribution device, liquid distribution, transportation or transfer device, etc., can solve the problems of waste, pollution, pouring and leakage of chemical raw materials, etc., to avoid pollution and waste, structure Powerful, enhanced vacuum suction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In the following, numerous specific details are set forth in order to provide a thorough understanding of the concepts underlying the described embodiments. It will be apparent, however, to one skilled in the art that the described embodiments may be practiced without some or all of these specific details. In other instances, well known processing steps have not been described in detail.

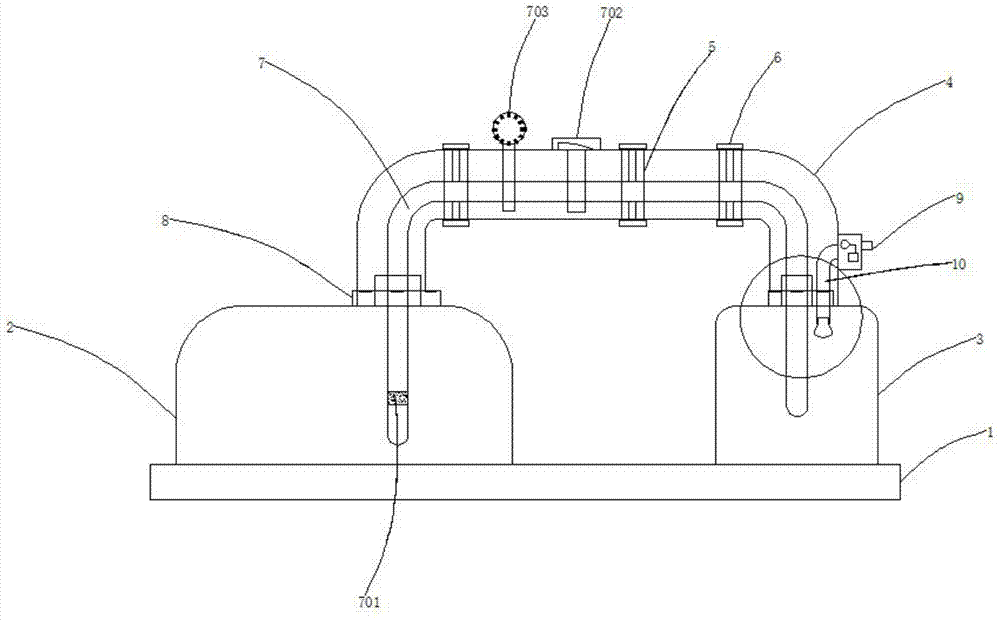

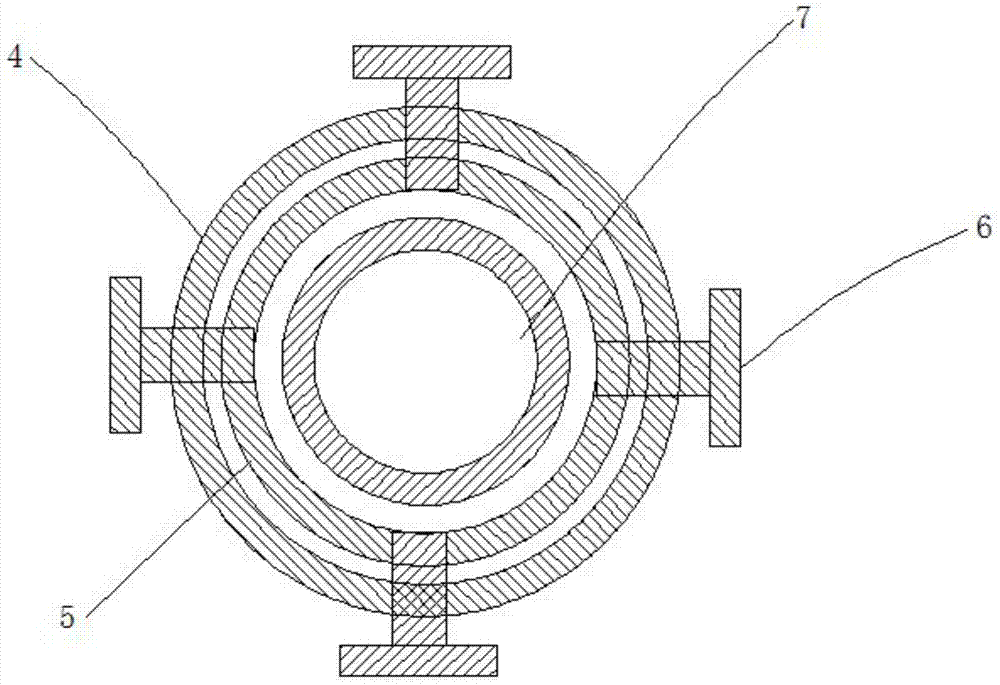

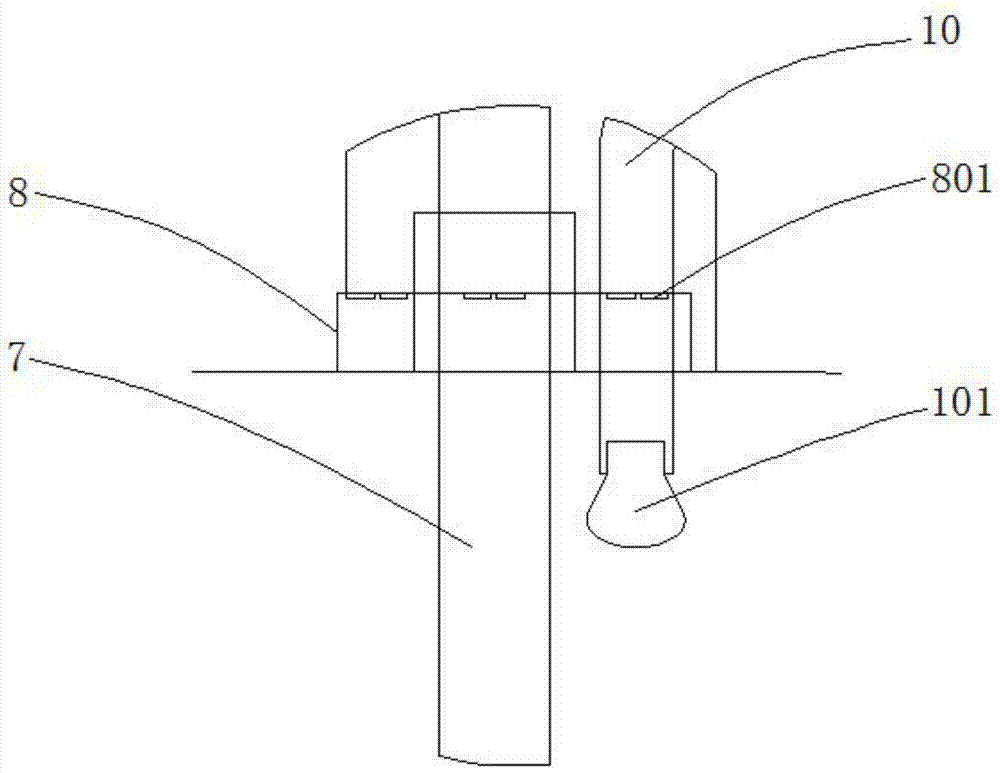

[0024] Such as figure 1 , figure 2 , image 3 As shown, it includes work table 1, raw material barrel 2, chemical barrel 3, pipe rack 4, clamp 5, locking screw 6, feeding pipe 7, suction cup 8, vacuum pump 9, suction pipe 10, guide sleeve 101, filter screen 701, rotary valve 702, flow meter 703, controllable gas nozzle 801, the pipe frame 4 is located on the top of the raw material barrel 2, the clamp 5 is located on the inner wall of the pipe frame 4, which are several rings, the two are connected by welding, and the locking screws 6 It is located around the clamp 5, and the two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com