Hollow brick structure for installing in-wall heating pipe

A hollow brick and heating technology, which is applied to building components, building structures, buildings, etc., can solve the problems of hollow brick structures without practical heating and heat pipes, low shear and tensile strength of walls, and inability to be used as load-bearing walls.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

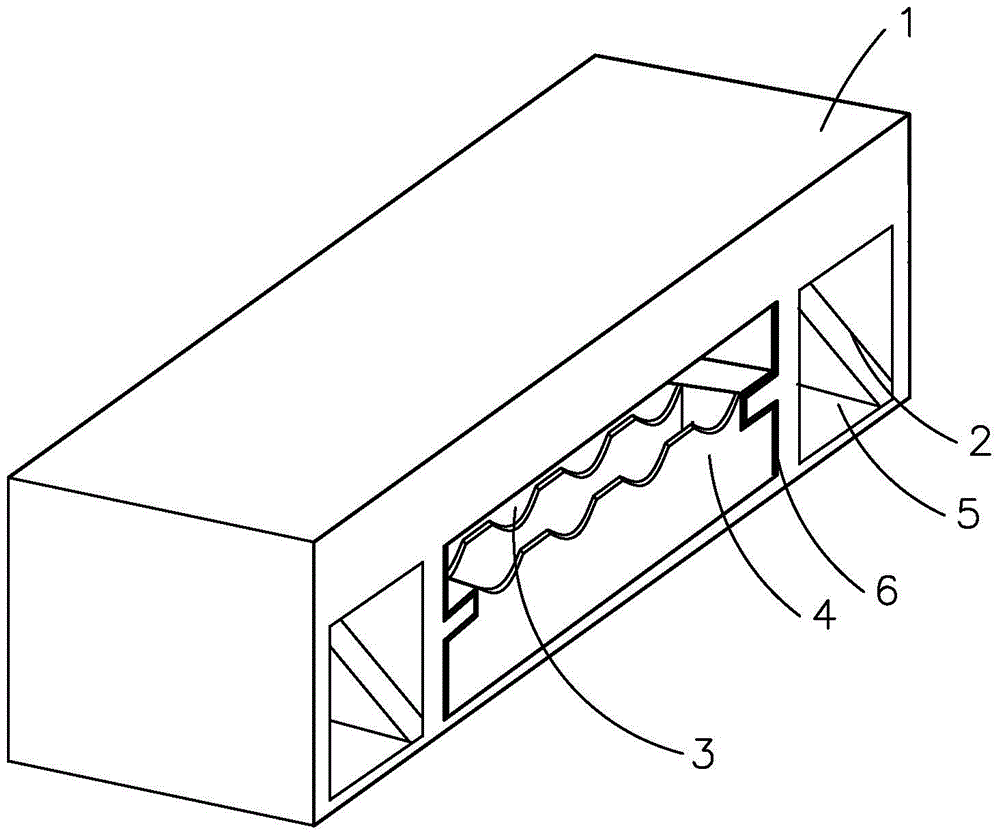

[0017] As shown in Figure 1, a hollow brick structure for installing heating in the wall includes a main body 1, and a heating space 3 for installing heating heat pipes is provided in the main body 1. A mounting plate 4 for installing heating heat pipes is also provided in the main body 1, The preferred mounting plate 4 is thermal insulation asbestos with a thickness of 10 mm, and the mounting plate 4 is placed horizontally in the heating space 3;

[0018] The upper end surface of the mounting plate 4 is provided with a heater heat pipe installation groove, and the installation groove is arc-shaped to match the outer surface of the heater heat pipe, which is beneficial to better install the electric heater heat pipe. Each heating heat pipe is installed in the corresponding installation groove, so that the heating heat pipe is close to the oute...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com