Method for diagnosing leading screw faults

A fault diagnosis and fault diagnosis model technology, applied in the direction of biological neural network models, can solve the problems of manual feature extraction, limited nonlinear expression ability of shallow network, etc., and achieve strong nonlinear expression ability and good fault identification ability , the effect of strong discrimination ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

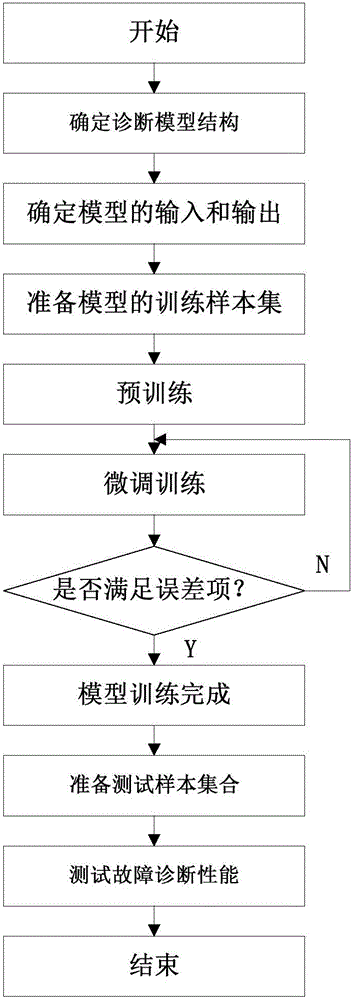

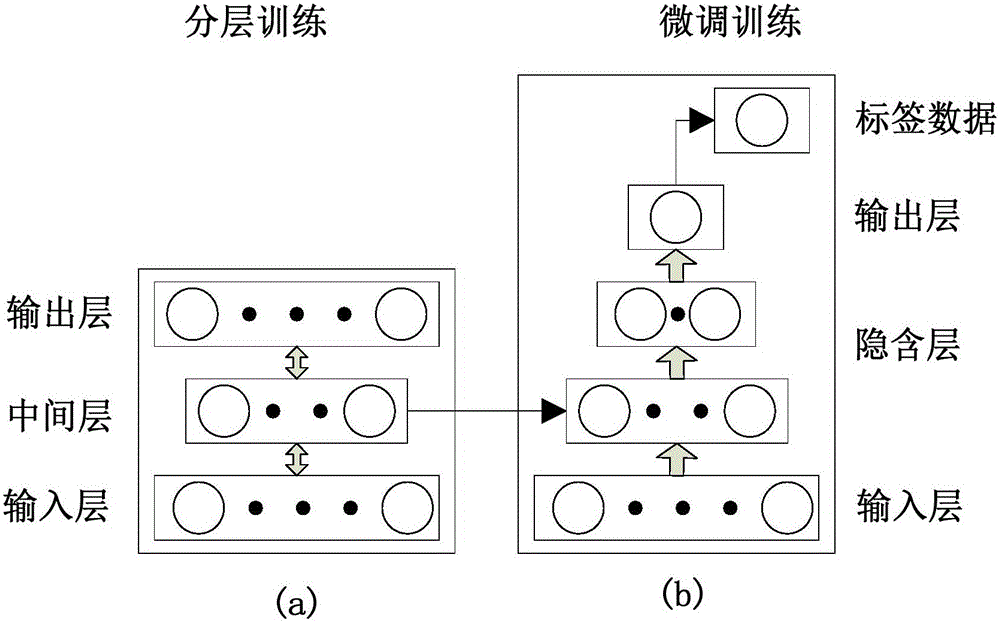

[0046] The present invention will be further described below in conjunction with the drawings. A lead screw fault diagnosis model based on feature learning, comprising the following steps:

[0047] 1. Establish a network structure with feature learning ability

[0048] 1. Determine the structure of the diagnostic model

[0049] The diluted self-encoder deep neural network structure is adopted, the recognition model of the network is selected from the Softmax regression classifier, and the hidden layer of the network is selected from the second layer.

[0050] 2: Determine the number of inputs to the fault diagnosis model

[0051] The fault diagnosis model has m input nodes, and the input signals of m nodes constitute an input vector x, expressed as follows:

[0052] x=(x1 ,x 2 ,...,x m )

[0053] where x i is the i-th input node of the model, i=1,2,...,m;

[0054] In this example, the number m of input nodes is 12. Respectively time-domain eigenvalues: root mean squar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com