Oil pump cover electrode insulation conduction test bench

A technology of conduction test and electrode insulation, applied in the direction of testing dielectric strength, etc., can solve problems such as low efficiency, poor detection accuracy, and slow detection speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

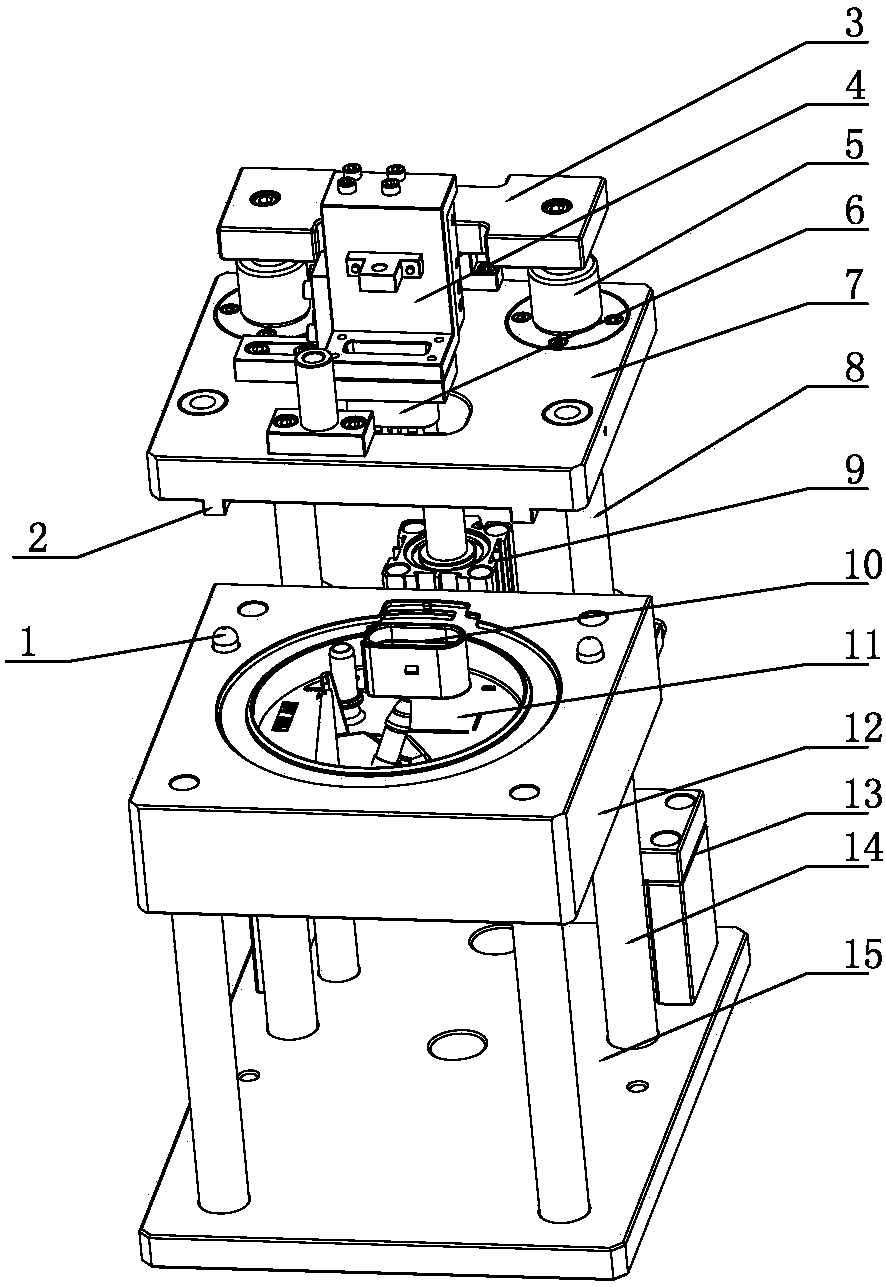

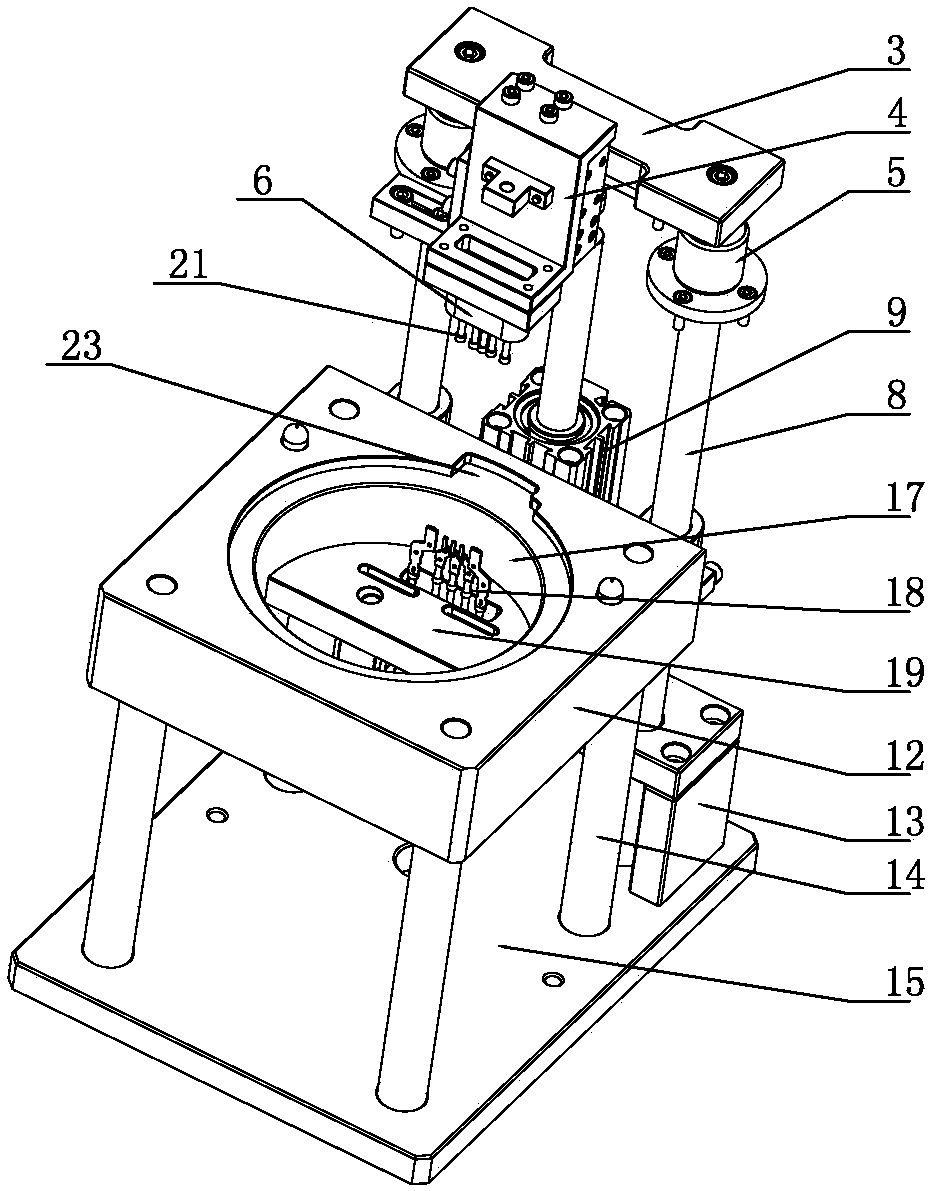

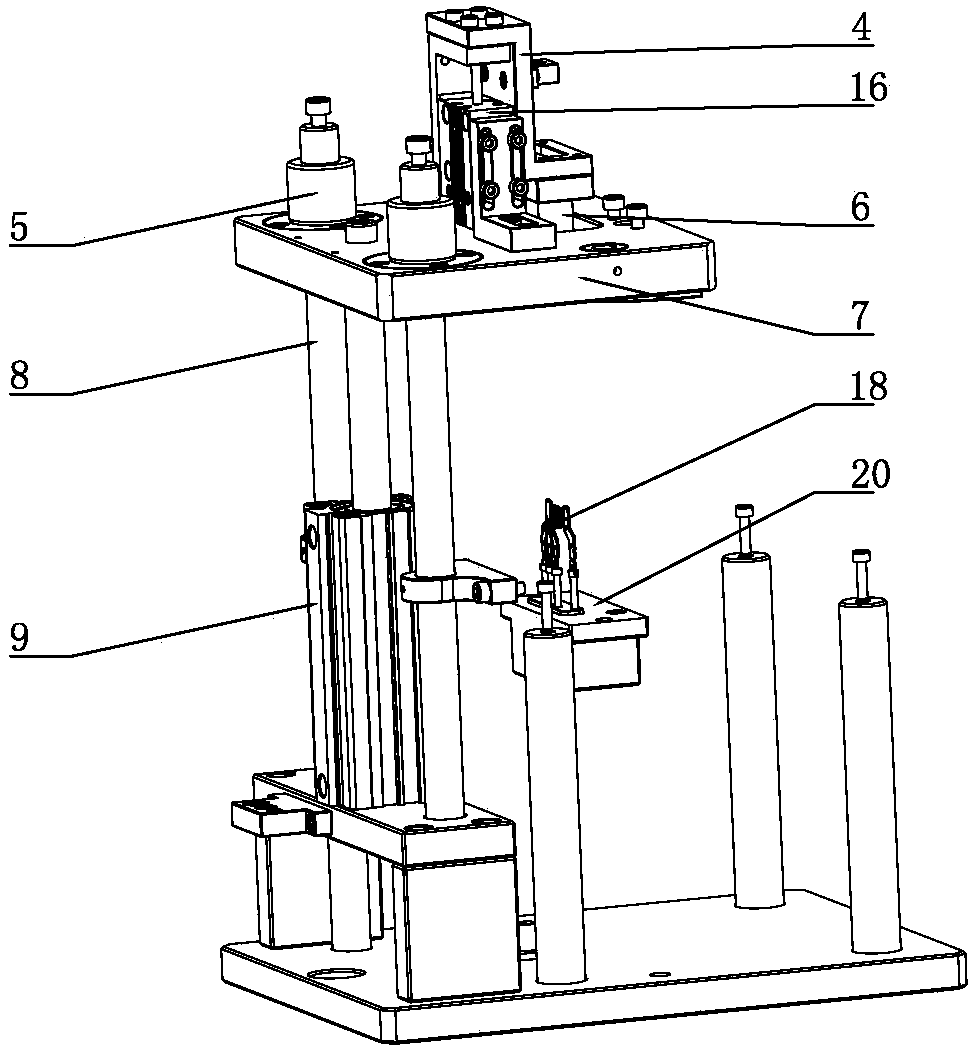

[0017] Such as Figure 1-5 As shown, it is an oil pump cover electrode insulation conduction test bench, its structure includes a base 15, four support rods 14 are vertically arranged on the base 15, a supporting platform 12 is arranged horizontally on the upper end of the supporting rod 14, and a support platform 12 is arranged in the center There is a stepped hole 17 for placing the oil pump cover 11 horizontally. A positioning notch 23 is provided on the upper edge of the stepped hole 17. The positioning notch 23 coincides with the positioning flange 24 on the side of the oil pump cover 11; the inner and lower sides of the stepped hole 17 are provided with Inner support platform 19, the lower side of inner support platform 19 is fixed with lower test electrode holder 20, the lower test electrode 18 on the lower test electrode holder 20 protrudes upwards through the inner support platform 19; the lower test electrode holder 20 is provided with longitudinal The chute 27 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com