Automatic charging pile for foot-type robot

A technology of automatic charging and robot motion, applied in electromechanical devices, current collectors, electric vehicles, etc., can solve the problem of footed robots running out of power and unable to connect to charging piles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

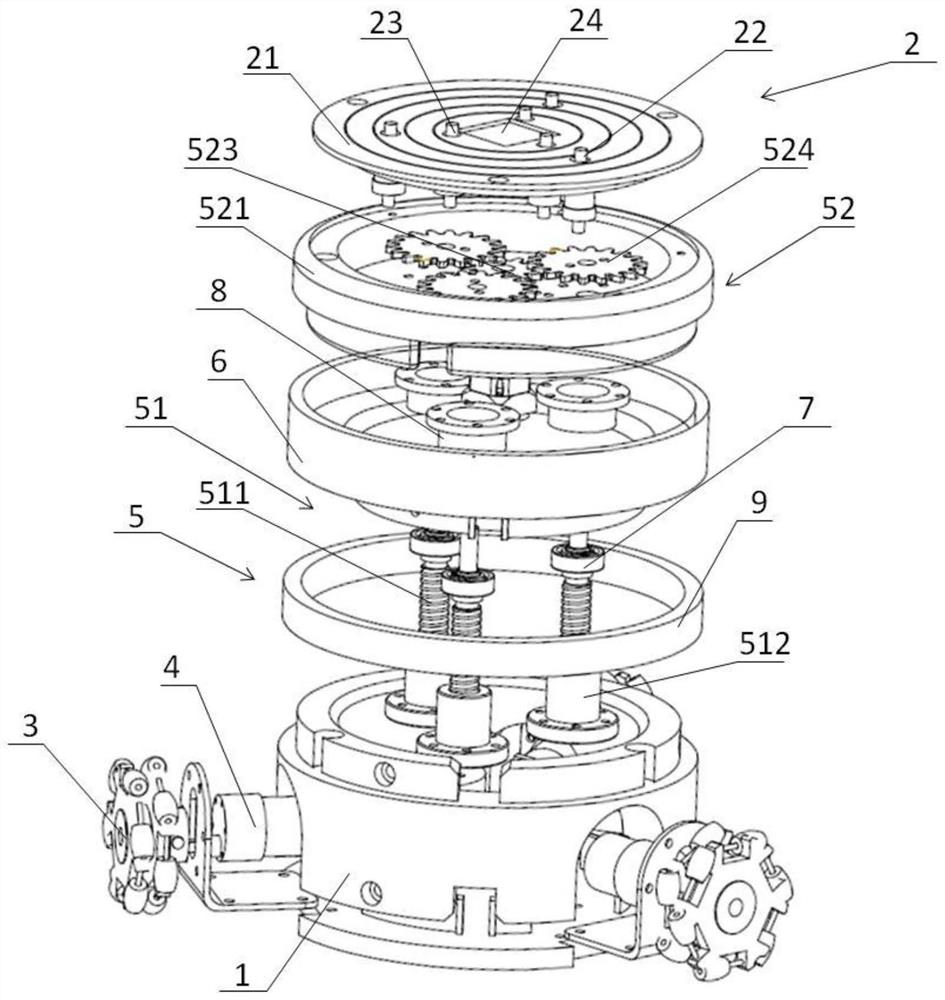

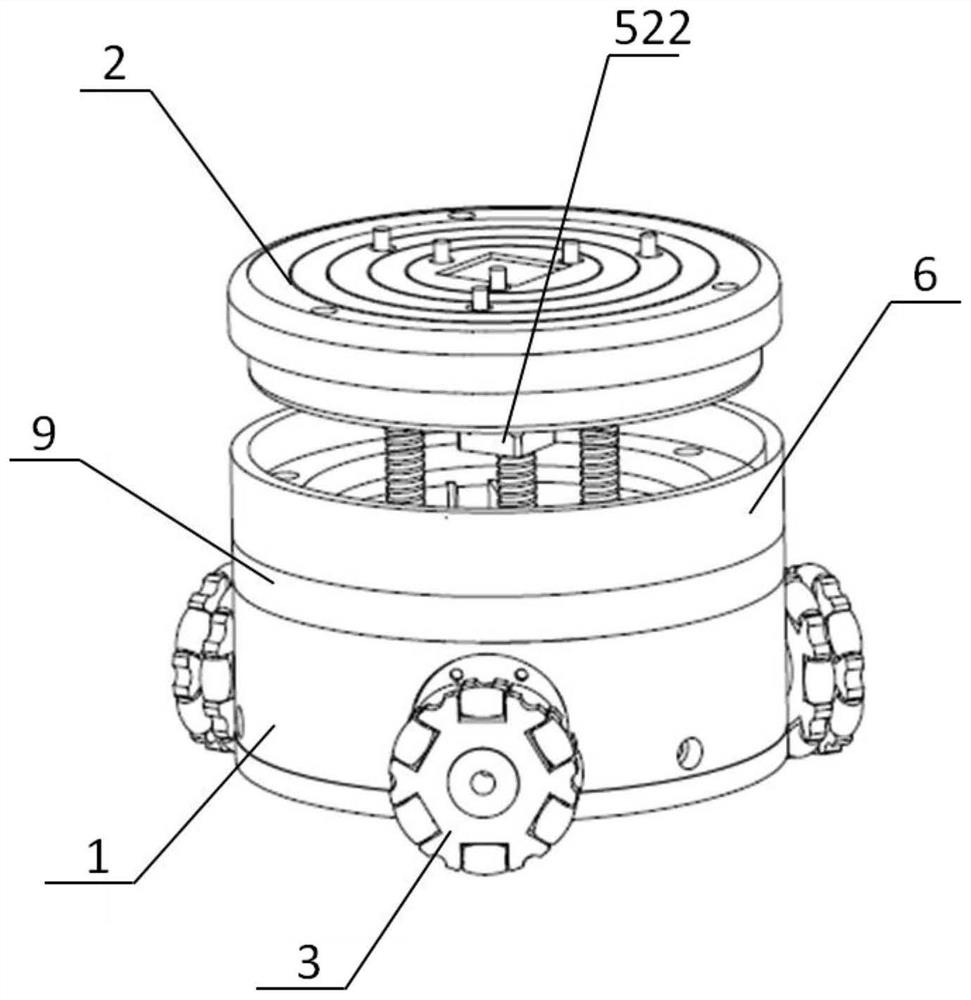

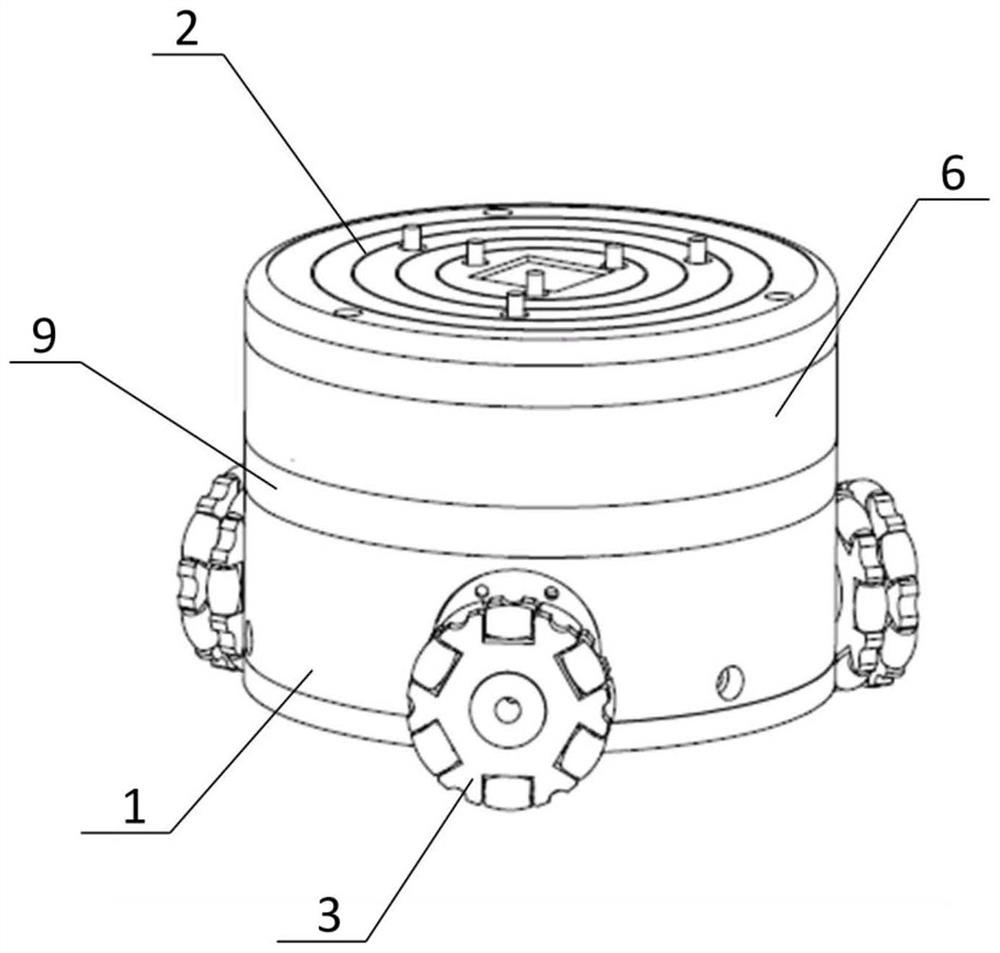

[0023] The specific implementation manners of the present invention will be described below in conjunction with the accompanying drawings.

[0024] Please also refer to Figure 1 to Figure 3 , the invention discloses an automatic charging pile for a legged robot, which includes a base 1 and a charging part 2, the charging part 2 is arranged on the top surface of the base 1, and the charging part 2 is used to connect with the legged robot to charge the legged robot Perform charging operation. In order to realize the movement of the charging pile, the base 1 in this embodiment is provided with an omnidirectional wheel 3, the omnidirectional wheel 3 is connected with the base 1, and the omnidirectional wheel 3 drives the base 1 to move toward the legged robot. At the same time, for the convenience of the charging pile Movement, three omni-directional wheels 3 evenly spaced on the base 1 in this embodiment, the omni-directional wheels 3 are connected to the base 1 through the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com