Sandstone picture, and making method and making apparatus thereof

A production method and sandstone technology, applied in the field of inkjet painting, can solve the problems of low production efficiency and inability to form large-scale quantitative production, and achieve the effect of improving production efficiency and reducing painting skill requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

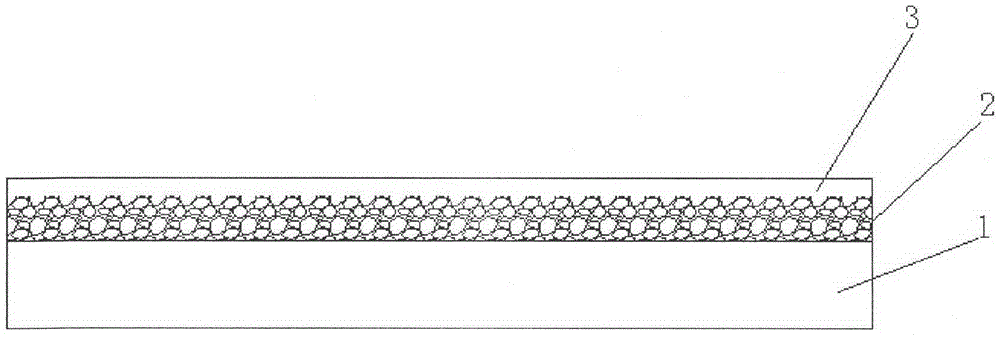

[0025] A method for making a sandstone painting, comprising the following steps:

[0026] Step 101: Spraying gravel particles containing viscous substances or simulated gravel particles on the slab base to obtain a sandstone slab;

[0027] Step 102: Printing a pattern on the viscous-containing gravel particle layer or the simulated gravel particle layer of the sandstone slab.

[0028] The production method of the sandstone painting in the above embodiment adopts a mechanized method to make the sandstone painting, which saves the steps of artificial coloring and manual pasting, which not only improves the production efficiency, but also reduces the requirements for the painting skills of the staff, so that the sandstone painting can be Large-scale production.

[0029] The specific process of the production method of the above-mentioned sandstone painting is: first select a flat base, spray gravel particles or simulated gravel particles on its surface, so that the two are bonde...

Embodiment 2

[0043] A kind of preparation method of sandstone painting comprises the following steps:

[0044] (1) Make a sandstone attachment layer on the flat base.

[0045] First of all, choose the white PVC foam board that can make the sandstone layer (real stone paint, itself sticky) adhere firmly as the flat base layer, and cut it according to the required size. Then connect the real stone paint spray gun to a 7.5KW air compressor, and use high-pressure airflow to evenly spray the real stone paint on the flat base plate and then dry it. After drying, use a bristle brush to remove the unstable residual sand on the surface to form a sandstone slab.

[0046] (2) Print the outline of the pattern on the sandstone plate prepared in the above step (1).

[0047] The pattern to be made is set in the computer plane image processing software (such as Photoshop and other software) to match the size of the pattern with the size of the plate. Use the filter sketch-photocopy function in the comp...

Embodiment 3

[0054] This embodiment also provides a device used in the method for making the above-mentioned sandstone painting, which includes a spray gun and an inkjet printer.

[0055] Wherein, the spray gun is used for: spraying gravel particles containing viscous substances or simulated gravel particles on the slab base to obtain a sandstone slab.

[0056] The inkjet printer is used for: printing patterns on the gravel particle layer containing viscous substances or the simulated gravel particle layer of the sandstone slab.

[0057] Various types of spray guns can be used for the above-mentioned tusk gun, which are mainly selected according to the properties of the gravel particles or simulated gravel particles. In addition, in order to improve the quality of the sandstone slab, an air compressor can also be added to the spray gun. The air compressor is used to: input high-pressure airflow to the spray gun, so that the spray gun uses high-pressure airflow to spray gravel particles or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com