Rail car battery trolley self-locking device

A self-locking device and battery technology, which is applied in locomotives, vehicle parts, transportation and packaging, etc., can solve the problems of easy disconnection of the battery supply circuit, easy cracking of the battery box cover door, easy damage of the battery pack, etc., to prevent easy breakage, The structure design is reasonable and reliable, and the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

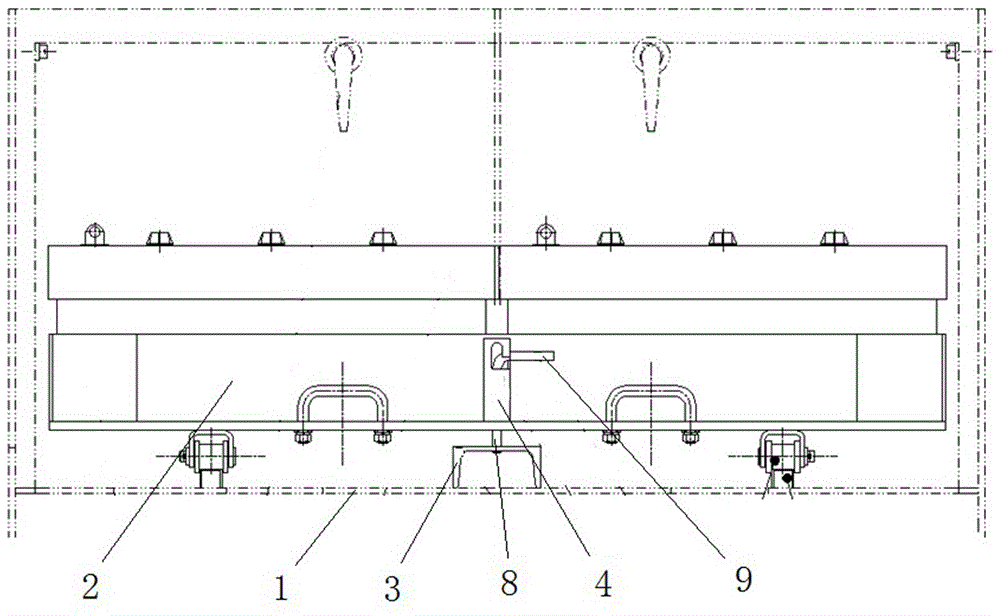

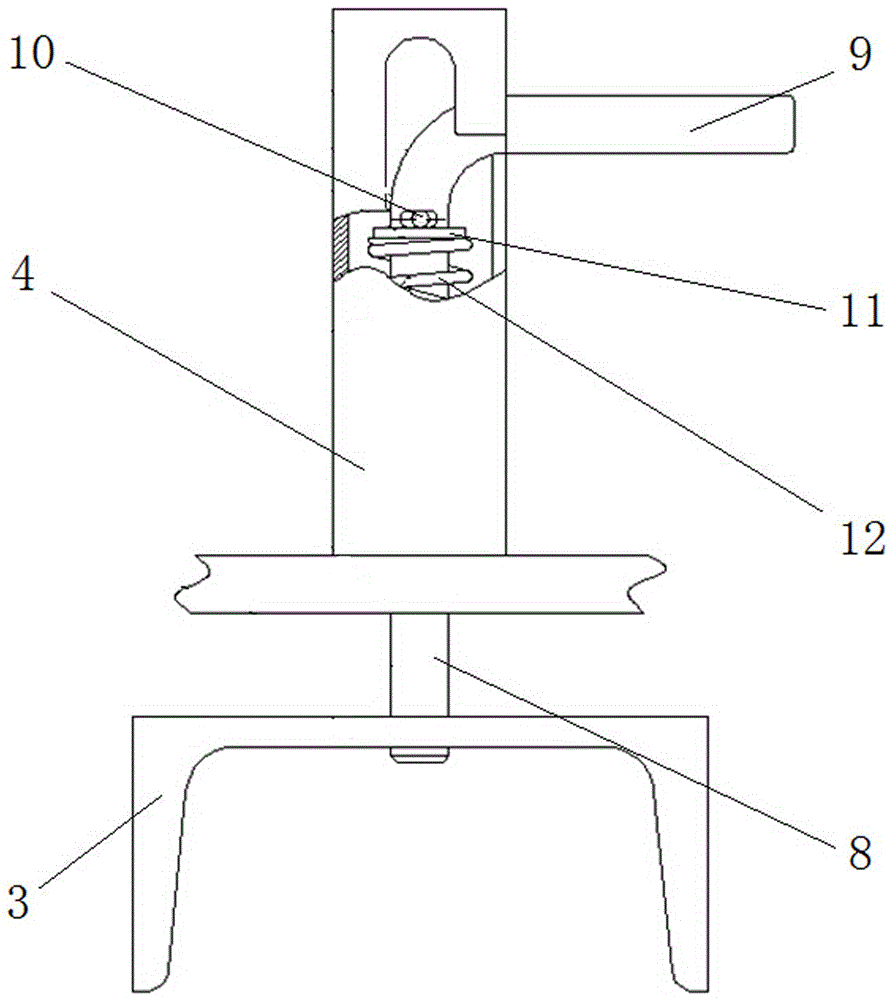

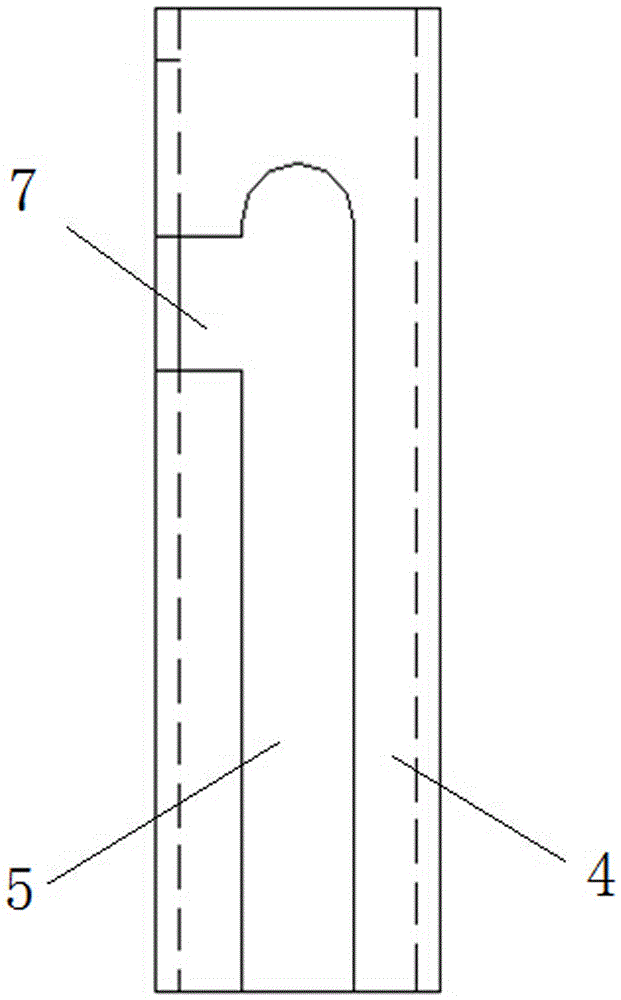

[0013] The battery trolley self-locking device of the rail car includes a battery box 1 and a battery trolley 2. The bottom plate of the battery box 1 is provided with an interlocking support 3 with a vertical jack, and the battery trolley 2 is fixed with an interlocking support 3. The corresponding interlocking sleeve 4 has a vertical positioning mobile locking groove 5 on the right side wall of the interlocking sleeve 4, and a vertical positioning mobile unlocking groove 6 is provided on the front wall of the interlocking sleeve 4. Between the positioning movement locking groove 5 and the vertical positioning movement unlocking groove 6, there is a horizontal sliding groove 7 communicating with the two. The interlocking sleeve 4 is provided with a latch 8 inserted into the jack, and the upper end of the latch 8 is provided with a And the rotating rod 9 that is arranged horizontally, the latch 8 is worn with a zinc cotter pin 10, the lower side of the zinc cotter pin 10 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com