Throat offset aerodynamic vectoring nozzle with vertical take-off and landing function and control method

A technology of vertical take-off and landing and vectoring nozzle, which is applied in the field of aircraft, can solve the problem that the thrust vectoring nozzle and vertical take-off and landing device cannot be designed into one body, etc., and achieve the effect of reducing structural weight, improving reliability and broadening application occasions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

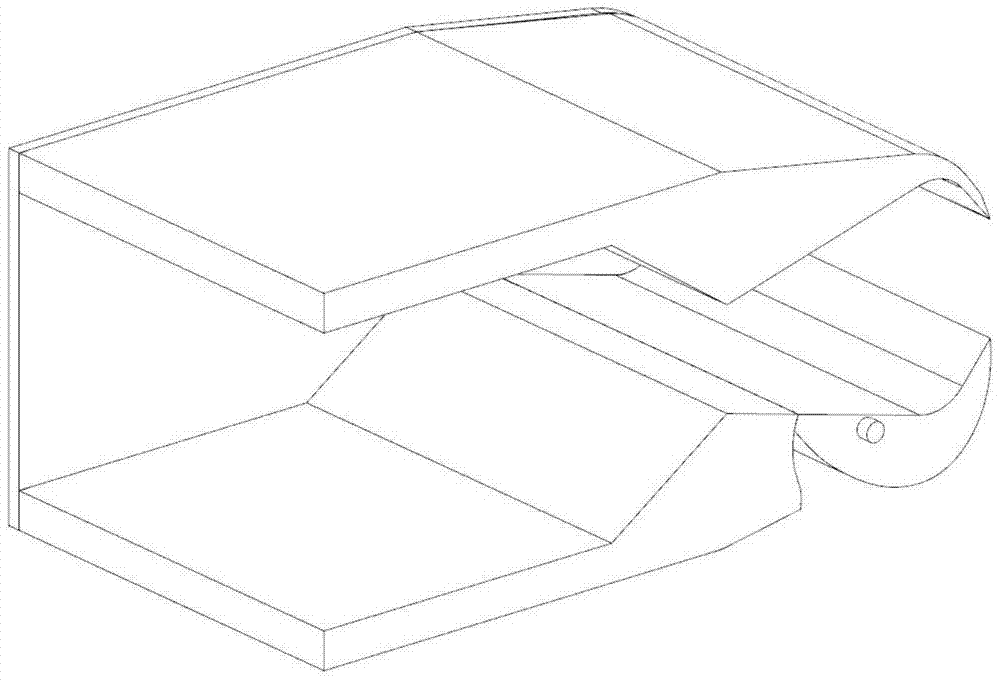

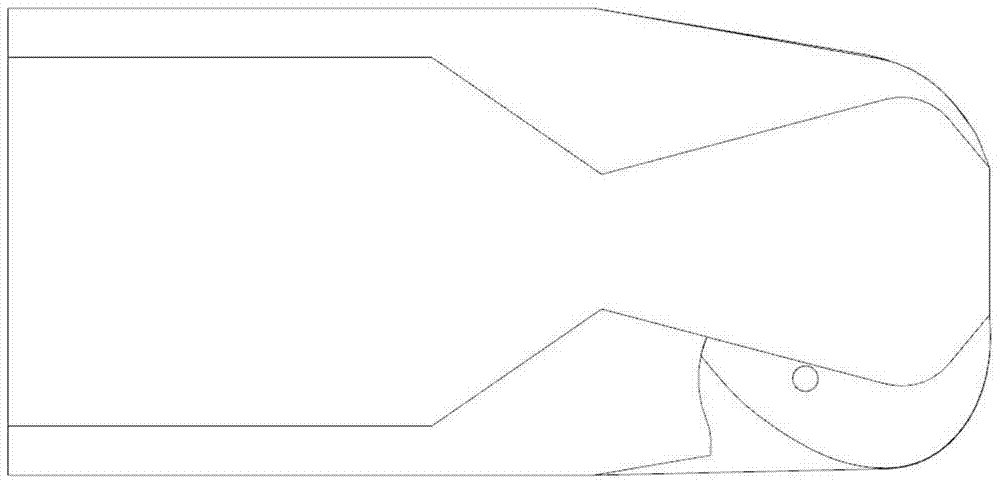

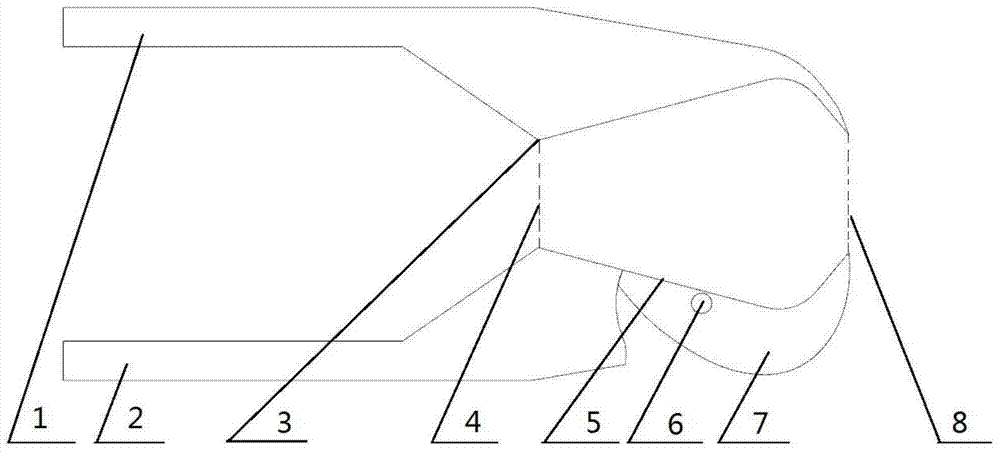

[0026] The invention is a throat offset pneumatic vectoring nozzle with vertical take-off and landing function. The air flow is changed from horizontal jetting backward to downward jetting by utilizing the rear body shape of the throat offset pneumatic vectoring jet nozzle, thereby realizing took off and landed vertically. Depend on figure 1 , figure 2 and image 3 It can be seen that the device is mainly composed of the nozzle upper wall 1, the nozzle lower wall 2, a throat point 3, a throat 4, the expansion and convergence section 5 at the front of the second throat, the rotating shaft 6, and the nozzle rear body 7. And components such as two throats 8 form. The rotating shaft support of the fixed rotating shaft 6 is fixedly connected with the front body of the throat offset type pneumatic vectoring nozzle, the rotating shaft 6 is controlled by the servo motor t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com