Board-level fan-out chip packaging device and manufacturing method thereof

A chip packaging, fan-out technology, used in semiconductor/solid-state device manufacturing, semiconductor devices, electric solid-state devices, etc., can solve problems such as development and cost reduction, and achieve the effect of improving performance, eliminating dependencies, and improving heat dissipation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

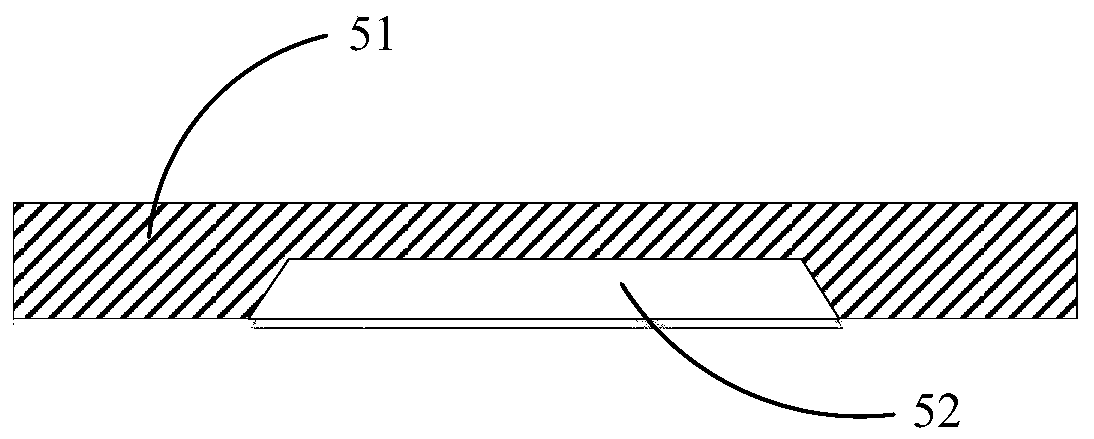

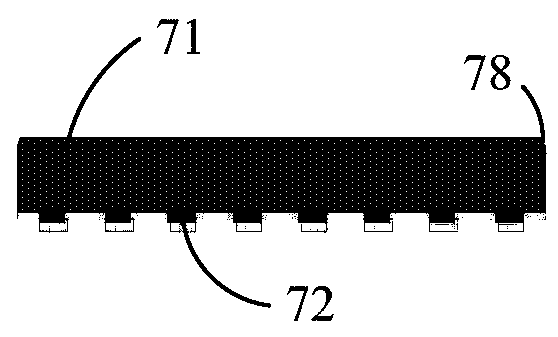

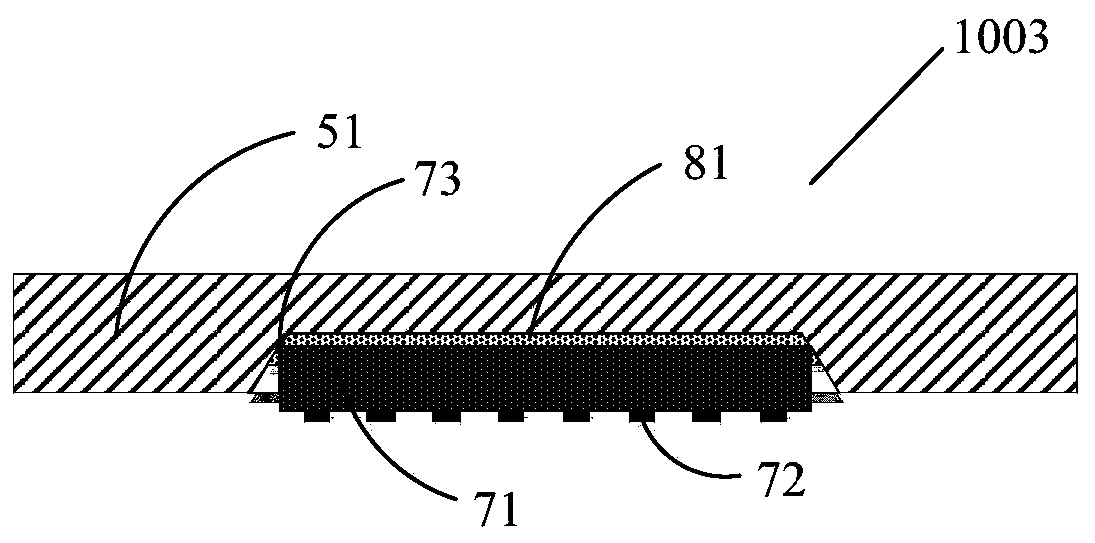

[0038] Therefore, the manufacturing method of the board-level fan-out type chip packaging device provided according to the embodiment of the present invention includes: providing a carrier board, on which a recess is provided, and the size of the recess is suitable for accommodating the chip; The back mount of the carrier board and the recess of the carrier board; the dielectric layer is arranged on the recessed side of the carrier board, on the carrier board and the chip; and by pressing the carrier board and the dielectric layer, the material of the dielectric layer can be filled to the in the gap between the recess of the carrier board and the chip.

[0039] The structure of the chip packaging device 10 according to the embodiment of the present invention has been reflected in the introduction of the above process flow, for example Figure 3-Figure 9 Its cross-section is shown. Such as Figure 4 As shown, the board-level fan-out chip packaging device 1004 includes: a carr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com