Swing device and its adjustment method

An adjustment method and technology of silicon wafers, applied in photovoltaic power generation, electrical components, climate sustainability, etc., can solve problems such as complex methods and affecting the production efficiency of crystalline silicon solar cells, so as to improve production efficiency, fast chip placement, The effect of solving the patch problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

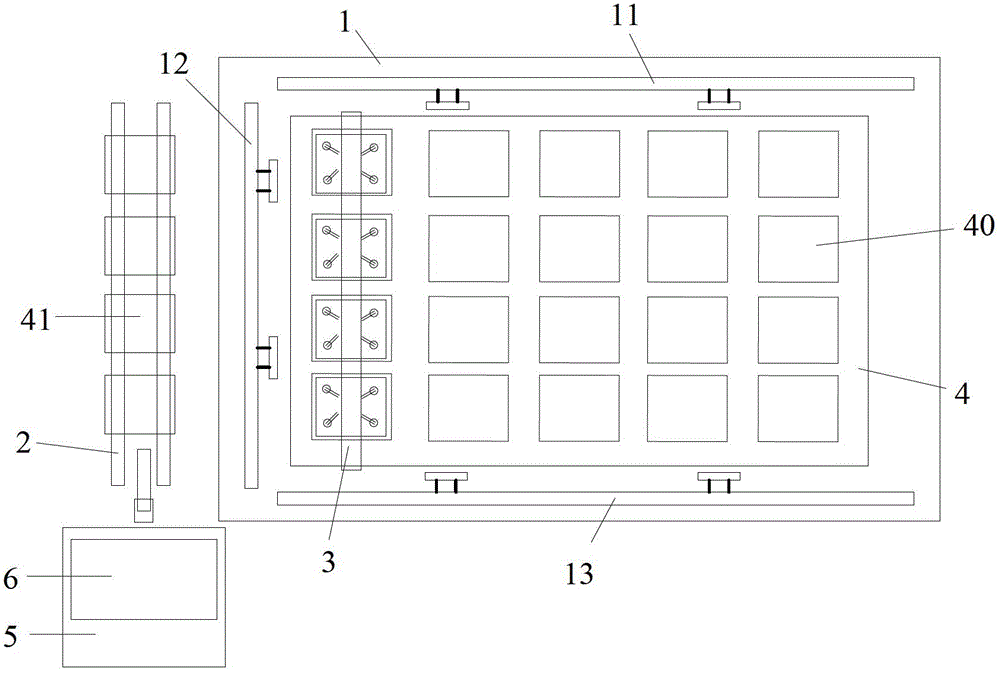

[0033] Such as figure 1 As shown, the film swing device provided by the embodiment of the present invention includes a loading platform 1 , a conveyor belt 2 and a gantry 3 . The loading platform 1 is used to carry the carrier plate 4, and the carrier plate 4 is provided with several slots 40 for placing silicon wafers 41; the loading platform 1 is provided with at least three positioners for adjusting from at least three directions And fix the position of the carrier board. As a preferred solution, the number of locators in this embodiment is three, and the first locator 11, the second locator 12, and the third locator 13 are respectively arranged on the front side, the left side and the left side of the loading platform 1. The rear side, that is, exerts pressure on the car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com