Chip gland jig and process method thereof

A technology of chips and fixtures, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of lower product yield, inconsistent total height of chips and glue, and inability to accurately control the paste height, so as to improve the placement quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. For ease of description, spatially relative terms (such as "below," "beneath," "lower," "above," "upper," etc.) may be used to describe the relationship between one element or component and another shown in the figures. Component or part relationship. Spatially relative terms encompass different orientations of the device in use or operation in addition to the orientation depicted in the figures. The device may be otherwise oriented (rotated 90 degrees or at other orientations) and the spatially relative descriptions used herein should be interpreted similarly accordingly.

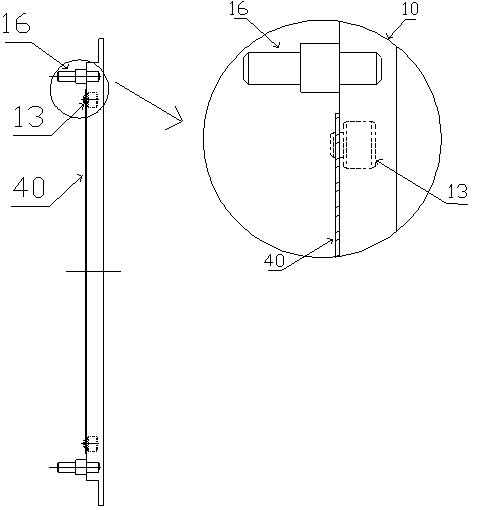

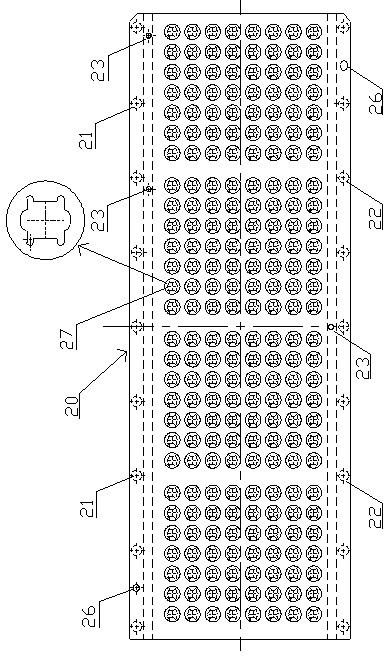

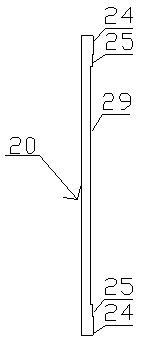

[0057] A chip capping jig of the present invention comprises a carrier 10, a stencil plate 20 and a stencil plate 30 from bottom to top, and a substrate 40 is placed between the carrier 10 and the stencil plate 20, as Figure 8 shown. Generally, one carrier 10 corresponds...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com