Adjustment mechanism for adjusting jaws of shear

A technology of adjusting mechanism and shearing machine, which is applied to cutters, shearing devices, earthmoving machines/shovels and other directions for shearing machine devices, and can solve the problems of cost, redundancy and cumbersomeness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

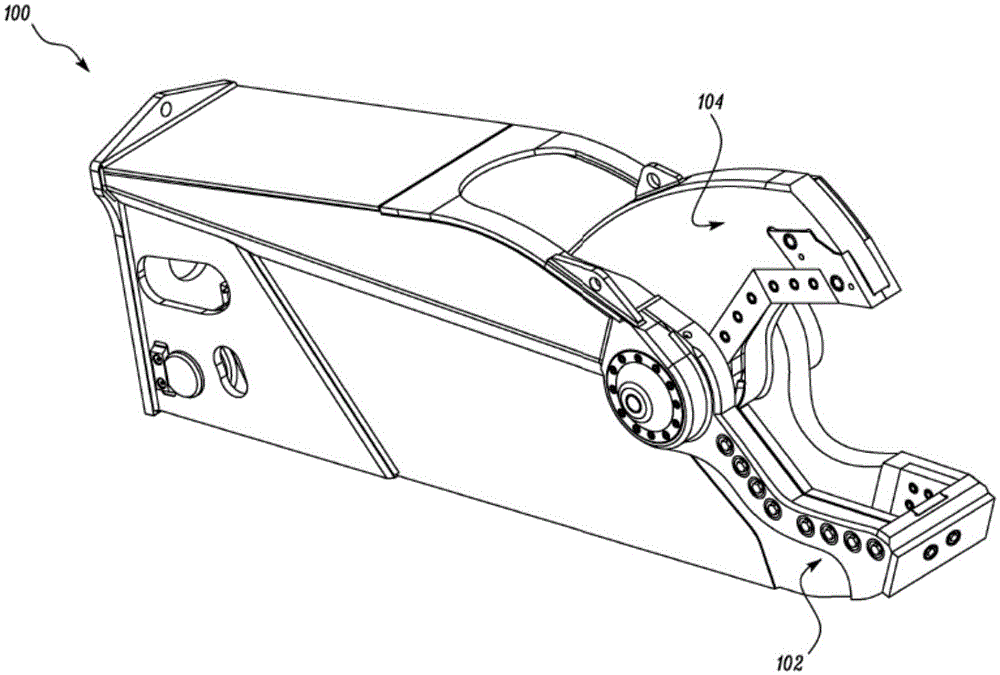

[0013] The invention relates to an adjustment mechanism for adjusting the jaws of a shearing machine. figure 1 A front perspective view of a shear 100 according to an exemplary embodiment of the present invention is shown. In one embodiment, the shearer 100 may be a shearer of the type commonly used for heavy construction machinery to shear rare earth materials, lumber, or building materials. In one embodiment, shearer 100 may be a hydraulic shearer configured to be hydraulically powered using brakes and trunnion linkages. In another embodiment, shearer 100 may be an electric shearer. Although the description focuses on hydraulic shears, it is understood that the apparatus and method can be similarly applied to other types of shears 100 .

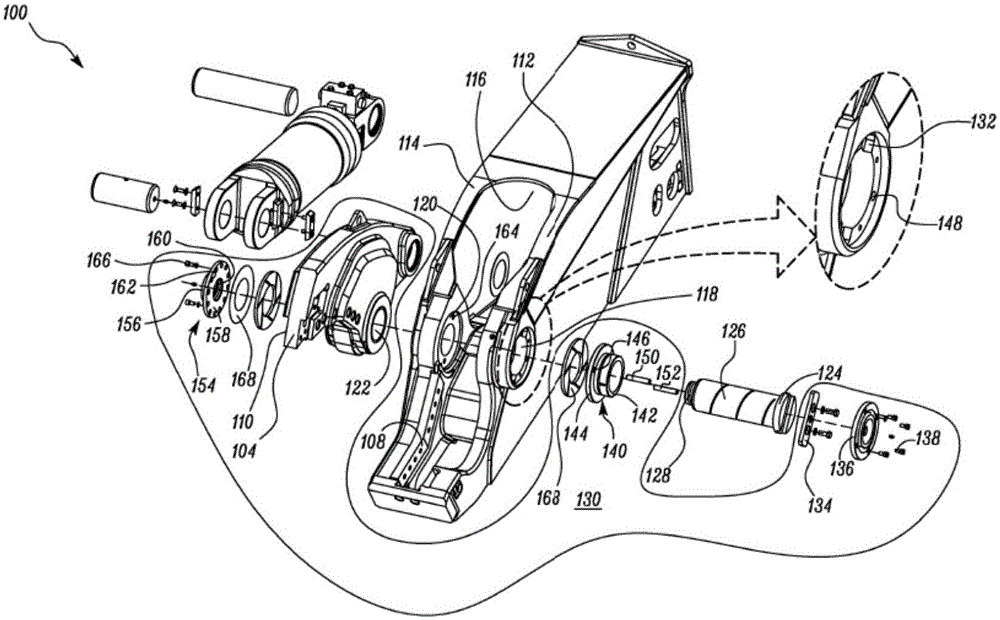

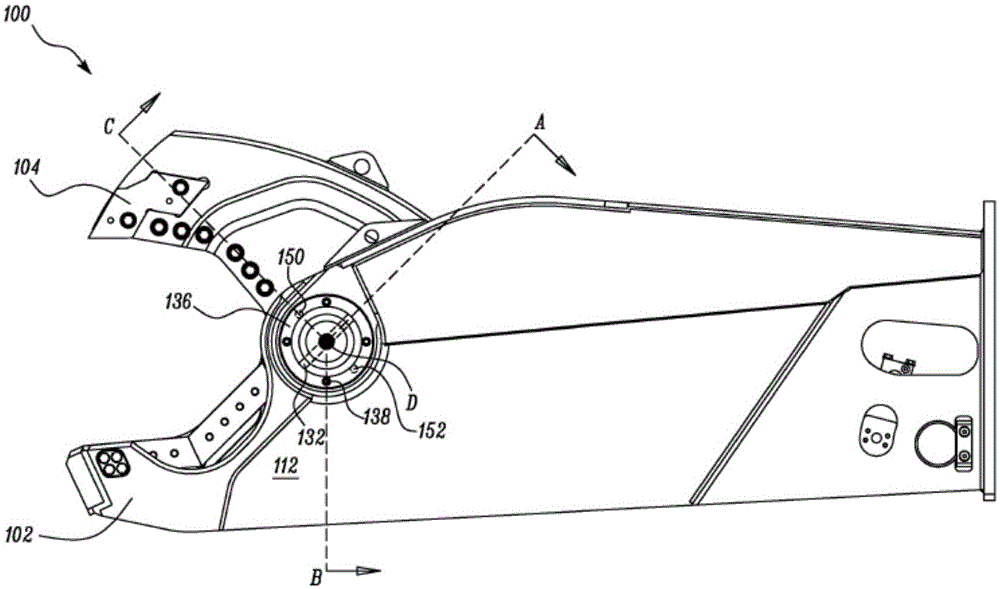

[0014] figure 2 An exploded view of hydraulic shear 100 is shown. The hydraulic shear 100 includes a first jaw 102 , a second jaw 104 and a pivot pin 106 . in such as figure 2 In one embodiment shown, the first jaw 102 is a stationa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com