polyacrylate allophanate

A technology of allophanate and acrylate, applied in polyurea/polyurethane coatings, synthetic resin layered products, organic chemistry, etc., can solve problems such as over-sticking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

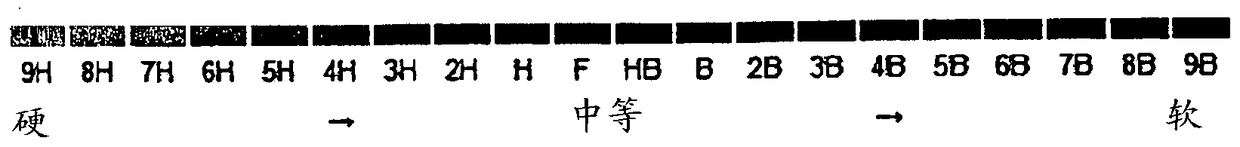

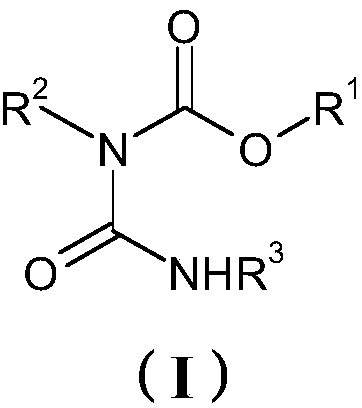

[0117] Embodiment 1: the preparation of the allophanate of formula (I)

[0118] In a fully stirred jacketed reactor introduce:

[0119] 425 g of HDI (2.53 mol), followed by 82 g of ethoxylated C 12 -C 18 Alcohol (0.23 mol) + 1.45 g of 1-butanol / 2-butanol mixture (75 / 25 in mass ratio m / m) and 5.85 g of catalyst KKAT XK-629 (at ambient temperature). The medium is heated to reach a temperature of 110° C. within 2 hours. The reaction medium is maintained at this temperature for about 1.5 hours.

[0120] The NCO content of the reaction medium was measured regularly by means of dibutylamine return dosing.

[0121] When the NCO content of the reaction medium corresponds to the desired theoretical content, the reaction is stopped by adding 0.066 g of p-toluenesulfonic acid.

[0122] After 15 minutes, the temperature of the reaction medium returned to ambient temperature.

[0123] The NCO content of the final reaction medium is 0.829 mol of NCO for 100 g.

[0124] Two successi...

Embodiment 2

[0129] Embodiment 2: Preparation according to the modified allophanate of the present invention

[0130] 80 g (0.205 mol) of (pentaerythritol) triacrylate (PETIA), 0.02 g of dibutyltin dilaurate (DBTL), 0.072 g of butyltin were introduced into a three-necked flask equipped with a cooling system, a mechanical stirrer and a nitrogen inlet. hydroxytoluene (BHT) and 100 g of dry toluene.

[0131] Then 61.4 g (0.185 mol) of the allophanate of the formula (I) of Example 1 were added dropwise with stirring, and the reaction medium was then heated to a temperature of 60°C.

[0132] The reaction was stopped after 7 hours when the NCO groups had reacted completely, and the reaction medium was returned to ambient temperature.

[0133] The solvent was then evaporated in vacuo.

Embodiment 6-8

[0142] Embodiment 6-8: by the product production coating of embodiment 2,3,4

[0143] The products of Examples 2, 3 and 4 were used to produce coatings which were crosslinkable under UV under the conditions shown in Table 3.

[0144] The urethane acrylate based formulation was adjusted to 50% dry extract with acetone and then 4% photoinitiator (Irgacure 500) was added.

[0145] 12 μm were applied on polycarbonate panels using a K-rod. After evaporating the solvent (30 minutes at 60° C. in an oven), the plates were kept under constant temperature and humidity conditions (50% RH, 23° C.) for 24 hours. The thickness of the coating is then 6 μm.

[0146] The plates were then crosslinked under UV (mercury lamp) under the conditions indicated in Table 3.

[0147] table 3

[0148]

[0149] Evaluation of the following properties was carried out 24 hours after crosslinking.

[0150] Gloss

[0151] Gloss was measured at an angle of 20° initially and after 50 reciprocations ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com