Plastic sheet hot-pressing processing and forming equipment and hot-pressing processing and forming technology

A plastic sheet, processing and molding technology, which is applied in the field of hot-pressing processing and molding equipment and hot-pressing processing and molding technology, can solve the problems of irregular stretching and deformation of patterns and characters, easy sticking of plastic, and large stretching ratio of the concave part of plastic containers, etc. , to achieve the slight degree of irregular stretching and deformation of the pattern, reduce the degree of irregular deformation, and avoid burning or severe burns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

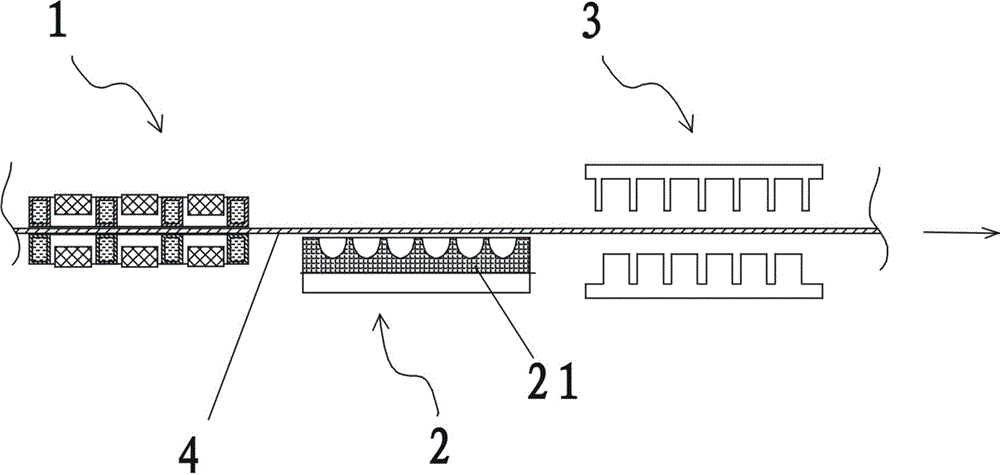

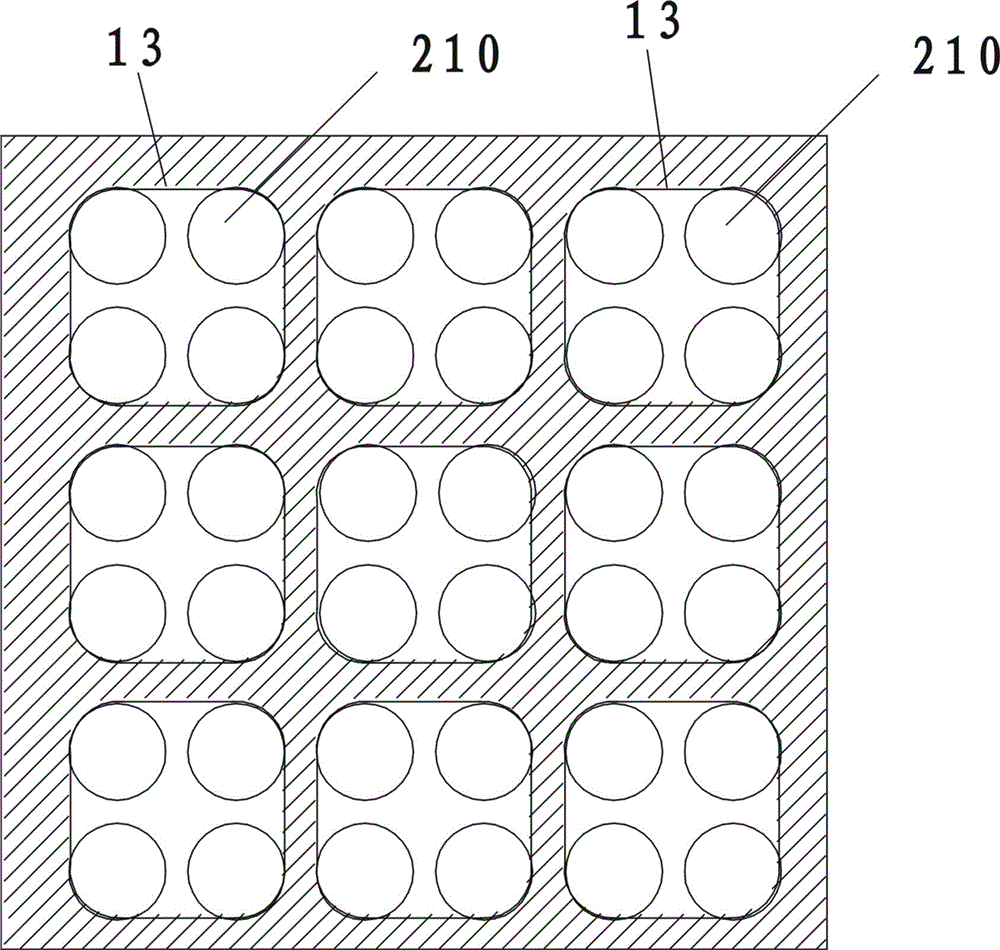

[0038] figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, the plastic sheet thermoforming equipment includes a heating mechanism 1, a pressing and forming mechanism 2, a punching and shearing mechanism 3, and a traction mechanism, wherein the heating mechanism 1, the pressing and forming mechanism 2, and the punching and shearing mechanism 3 are along the direction of plastic movement Arranged in sequence, the traction mechanism is arranged on both sides of the heating mechanism and the pressing and forming mechanism; the pressing and forming mechanism 2 is equipped with a mold 21, Figure 8 , Figure 9 As shown, thirty-six circular cavities 210 are formed in the mold 21, and each circular cavity 210 is distributed into six horizontal rows and six vertical columns. The surroundings of each circular cavity 210 are flat parts 211 around the cavity that are not depressed.

[0039] figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Fig...

Embodiment 2

[0042] A plastic sheet hot-pressing molding process, using the plastic sheet hot-pressing molding equipment of the above-mentioned embodiment 1, comprises the following steps:

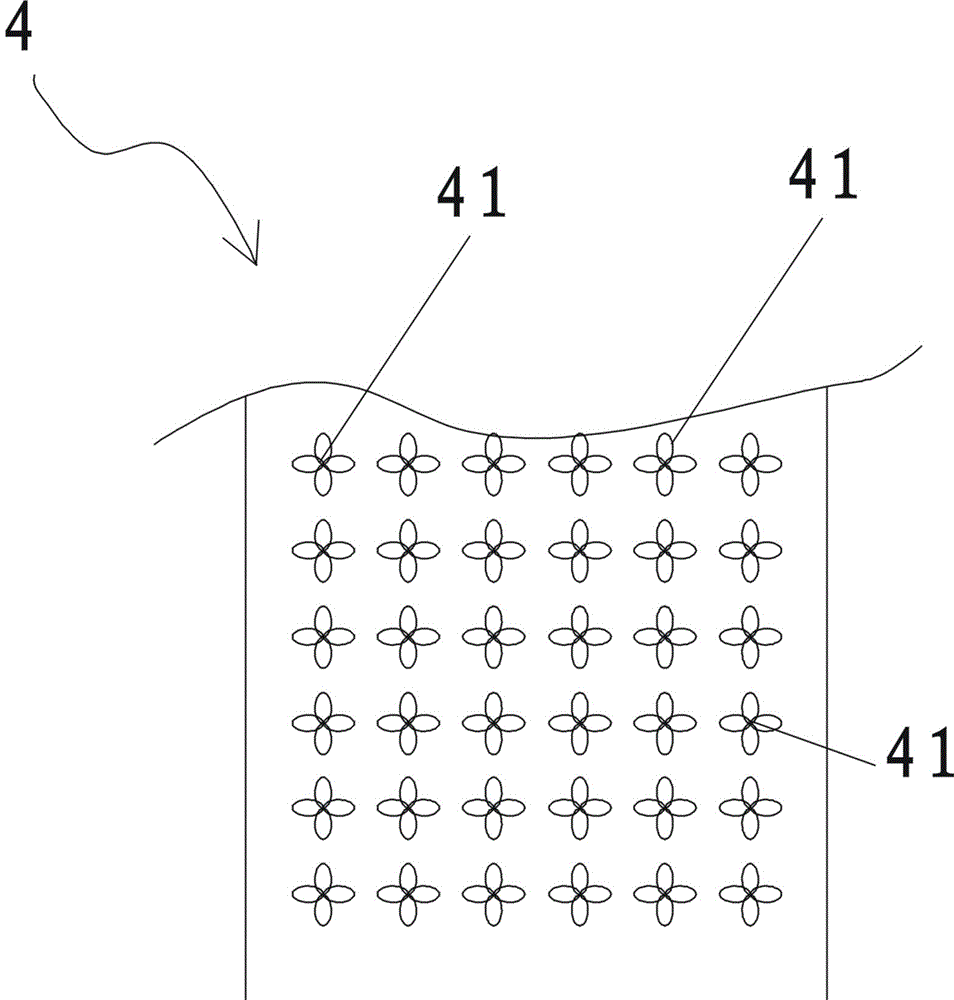

[0043] (1). The traction mechanism pulls the plastic sheet 4 forward, and the forward direction of the plastic sheet is as follows: figure 1 As shown by the arrow, wherein the plastic sheet is printed with multiple groups of plane patterns 41, and each group of plane patterns 41 is arranged into six rows and six columns, as Figure 11 As shown, and the spacing and position of each group of planar patterns 41 correspond to the spacing and position of the mold cavity 210; when the plastic sheet advances, the lower clamping frame 12 and the upper clamping frame 11 are opened to leave a vertical gap ,Such as Figure 4 As shown; (2). Constantly input cooling water 18 to the cooling channel 15 of the metal frame bar 14 through the inlet 16, and the cooling water 18 is discharged from the cooling channel 15 ...

Embodiment 3

[0045] Embodiment 3 is a plastic sheet hot-pressing molding process, which is roughly the same as Embodiment 2. The main difference between the two is that in the above step (3), after the lower clamping frame and the upper clamping frame are opened again, the position of the plastic sheet is kept still, and the pressing molding mechanism is moved to align the position of the mold cavity with the plastic sheet The corresponding position where the material is printed with a pattern; when the forming action is completed, remove the pressing forming mechanism. All the other are identical with embodiment two.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com