A combined positioning device and positioning method

A technology combining positioning and positioning methods, applied in the direction of measuring devices, instruments, etc., can solve the problems of distortion of extracted elements, unreasonable installation of probes, deterioration of measurement accuracy, etc., to improve measurement accuracy, shorten installation, adjustment and alignment time, The effect of reducing human measurement error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention is described in further detail below in conjunction with accompanying drawing:

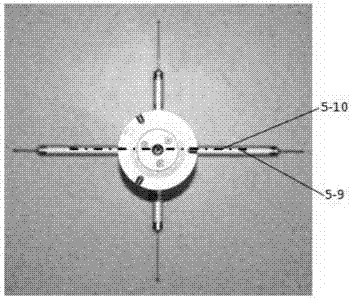

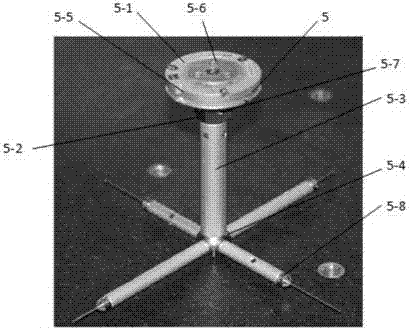

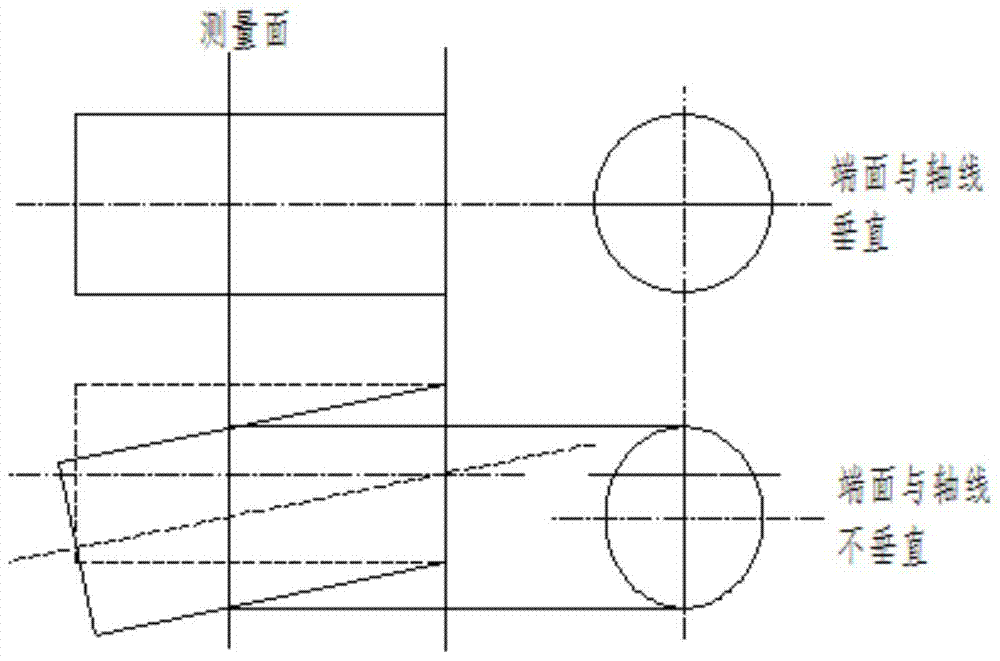

[0055] see Figure 5 to Figure 10 , the present invention provides a combined positioning device, including a base plate 1-1 and a support portion; a first guide rail 1-2 is arranged on the base plate, the first guide rail is parallel to the base plate, and a first slider 1-3 is arranged on the first guide rail and the second slide block 1-4, the first slide block and the second slide block can slide along the axial direction of the first guide rail, the first slide block and the second slide block are respectively provided with the first pointer type dial gauge 1 -5 and the second pointer dial gauge 1-6, the heads of the first pointer dial gauge 1-5 and the second pointer dial gauge 1-6 are all used to contact the datum surface of the measured workpiece; Move the first horizontal slider 1-3 and the second horizontal slider 1-4 horizontally according to the reference ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com