A multi-stage response automatic fire extinguishing device and its use method

An automatic fire extinguishing and responsive technology, applied in the direction of fire rescue, etc., can solve the problems of secondary damage, ineffective use, and complex engineering design of protective facilities, and achieve the goal of saving fire extinguishing agent consumption, reducing secondary damage, and strong operability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

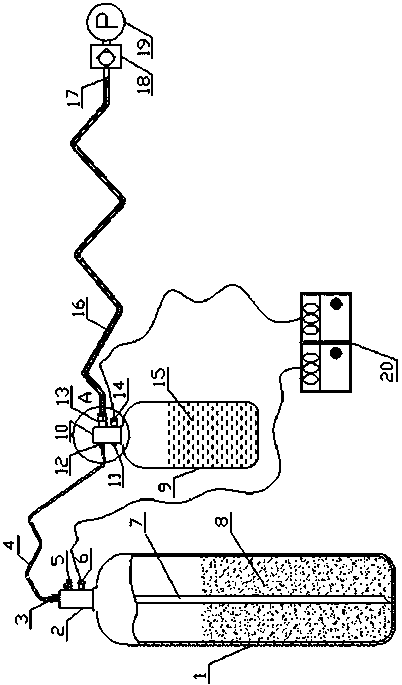

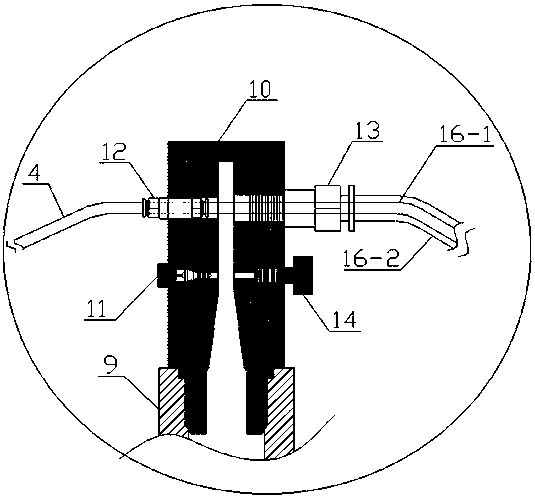

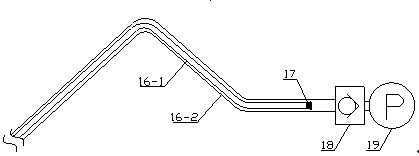

[0030] In order to understand the present invention more clearly, the present invention is described in detail in conjunction with the accompanying drawings and embodiments.

[0031] like Figure 1 to Figure 4As shown, a multi-stage response automatic fire extinguishing device includes a first pressure tank 1, a first bottle head valve 2, a connecting ball valve 3, a first inflation interface 5, a first pressure sensor 6, a siphon 7, and a second pressure tank 9. The second bottle head valve 10, the second inflation interface 11, the second pressure sensor 14, and also includes the hose 4, ABC type ultrafine dry powder fire extinguishing agent 8, double-head straight connector 12, common connector 13, heptafluoropropane or carbon dioxide fire extinguishing Agent 15, fire extinguishing pipe 16, end plug 17, check valve 18, pressure gauge 19, alarm controller 20.

[0032] The siphon tube 7 is placed in the first pressure tank 1, the upper end of the siphon tube 7 is connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com