Longitudinally pre-buried and fixed auxiliary support structure for climbing mold rack body

An auxiliary support and pre-embedded technology, applied in the direction of building structure support, building structure support, formwork/formwork/working frame, etc., can solve the problems of large manpower, material resources, construction waste, environmental impact, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

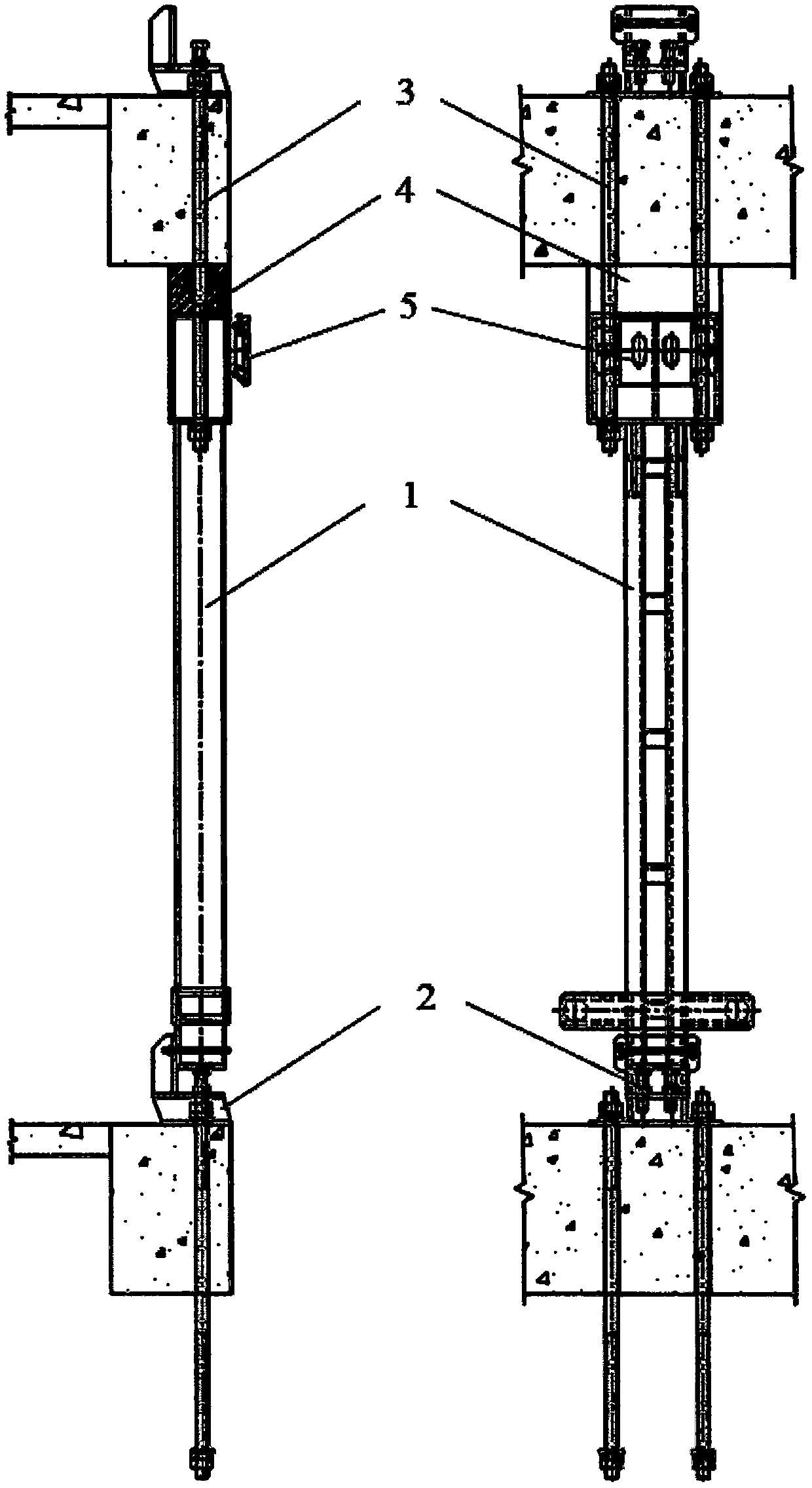

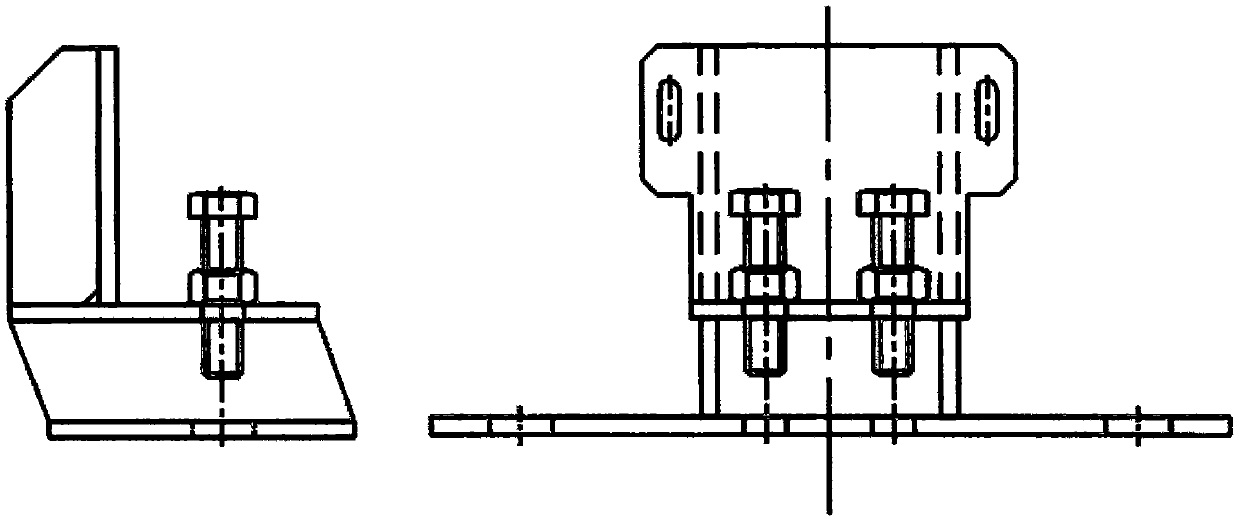

[0024] See figure 1 , an auxiliary supporting structure of a climbing formwork frame body that is pre-embedded and fixed longitudinally, including an auxiliary supporting steel column 1, a connecting seat 2, an embedded bolt 3, a backing plate 4 on the steel column, and a wall seat 5; the auxiliary supporting steel column 1 and The connecting seat 2 is connected to the core tube structural beam through embedded bolts 3; the auxiliary supporting steel column 1 is connected and fixed with the connecting seat 2 through U-shaped bolts; the backing plate on the steel column is installed between the auxiliary supporting steel column and the structural beam.

[0025] See figure 1 , Bolt holes are reserved at specified positions in the longitudinal direction of the core tube structural beam, and embedded bolts 3 penetrate vertically.

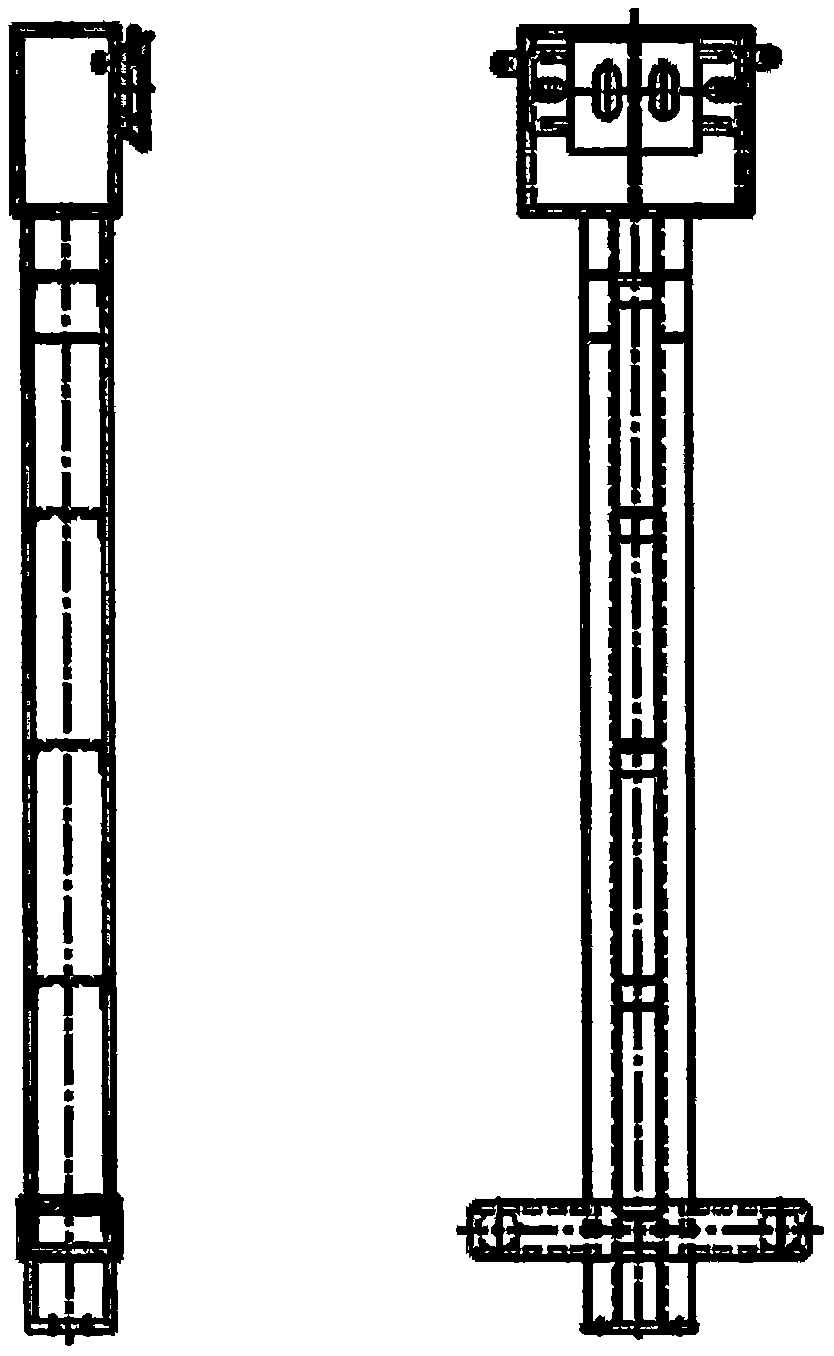

[0026] See figure 2 , the top of the auxiliary supporting steel column 1 is a cuboid box structure, the middle position inside the box is added with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com