Safe lithium ion battery and preparation method thereof

A lithium-ion battery, safe technology, applied in the direction of secondary batteries, battery components, circuits, etc., can solve the problems of low pass rate and low safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

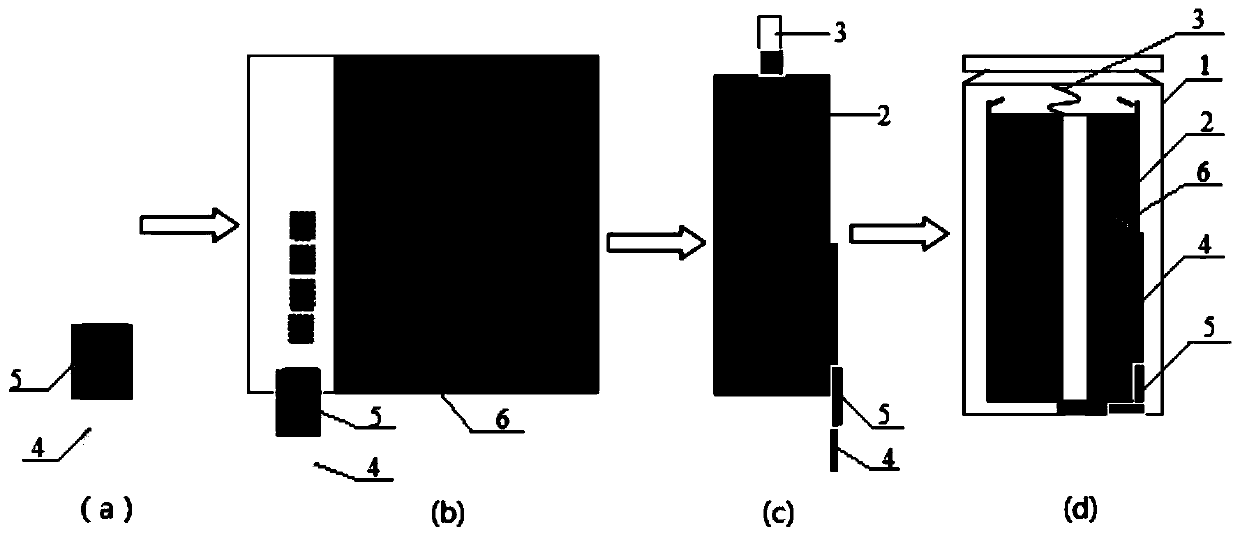

[0032] On the other hand, the embodiment of the present invention also provides a method for preparing the above-mentioned safe lithium-ion battery. The preparation method comprises the following steps, and the process is as follows: figure 2 Shown:

[0033] S01: Encapsulate the negative tab 4 with high temperature adhesive tape 5 ( figure 2 a);

[0034] S02: Cover the edge of one end of the negative electrode sheet 6 to be wound with the high-temperature adhesive tape 5 after encapsulation, and connect the negative electrode tab 4 to the blank part of the tail of the negative electrode sheet 6 ( figure 2 b);

[0035]S03: Wind the negative electrode sheet 6 connected with the negative electrode tab 4, the separator, and the positive electrode sheet (not marked in the figure) into a core ( figure 2 c), and put the winding core 2 into the casing 1 to complete the bottom welding and rolling groove process to form the final lithium ion battery ( figure 2 d), where one en...

Embodiment 1

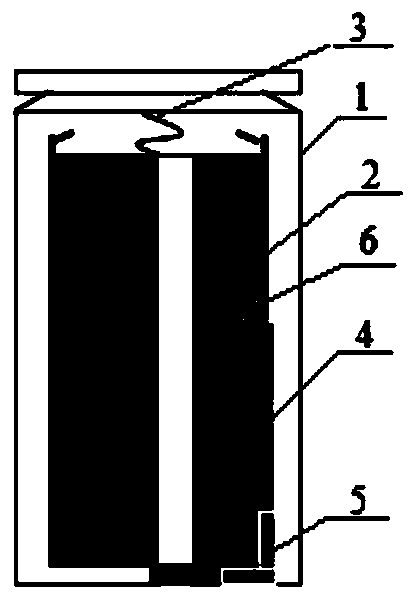

[0040] A cylindrical lithium-ion battery, the structure of which is as follows figure 1 shown. The lithium-ion battery comprises a casing 1 and a winding core 2 arranged in the casing 1, and a positive pole ear 3 and a negative pole ear 4; the negative pole ear 4 is connected to the tail of the negative electrode sheet 6 on the outer wall of the winding core 2, and the The negative tab 4 is arranged along the side wall and the bottom of the housing 1, and the bent part of the negative tab 4 at the connection between the side wall and the bottom of the housing 1 is covered with a high-temperature adhesive tape 5 with a thickness of 30 mm. The base material of the high temperature tape 5 contains PI, and the glue of the high temperature tape 5 contains PMMA. The length of the high temperature adhesive tape 5 adjacent to the side wall of the housing 1 is 4mm, the length of the high temperature adhesive tape 5 adjacent to the bottom of the housing 1 is 4mm, and the length of the ...

Embodiment 2

[0046] A cylindrical lithium-ion battery, the structure of which is as follows figure 1 shown. The lithium-ion battery comprises a casing 1 and a winding core 2 arranged in the casing 1, and a positive pole ear 3 and a negative pole ear 4; the negative pole ear 4 is connected to the tail of the negative electrode sheet 6 on the outer wall of the winding core 2, and the The negative tab 4 is arranged along the side wall and the bottom of the housing 1, and the bent part of the negative tab 4 at the connection between the side wall and the bottom of the housing 1 is covered with a high-temperature adhesive tape 5 with a thickness of 70 mm. The base material of the high temperature tape 5 contains PI, and the glue of the high temperature tape 5 contains PMMA. The length of the high temperature adhesive tape 5 adjacent to the side wall of the housing 1 is 6 mm, the length of the high temperature adhesive tape 5 adjacent to the bottom of the housing 1 is 6 mm, and the length of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com