Collecting pipe fixing mechanism capable of guaranteeing picture-taking quality

A technology of fixing mechanism and collection tube, which is applied in measurement devices, material analysis by optical means, instruments, etc., can solve the problems of inability to collect multiple angles and inability to capture the whole picture of the sample.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

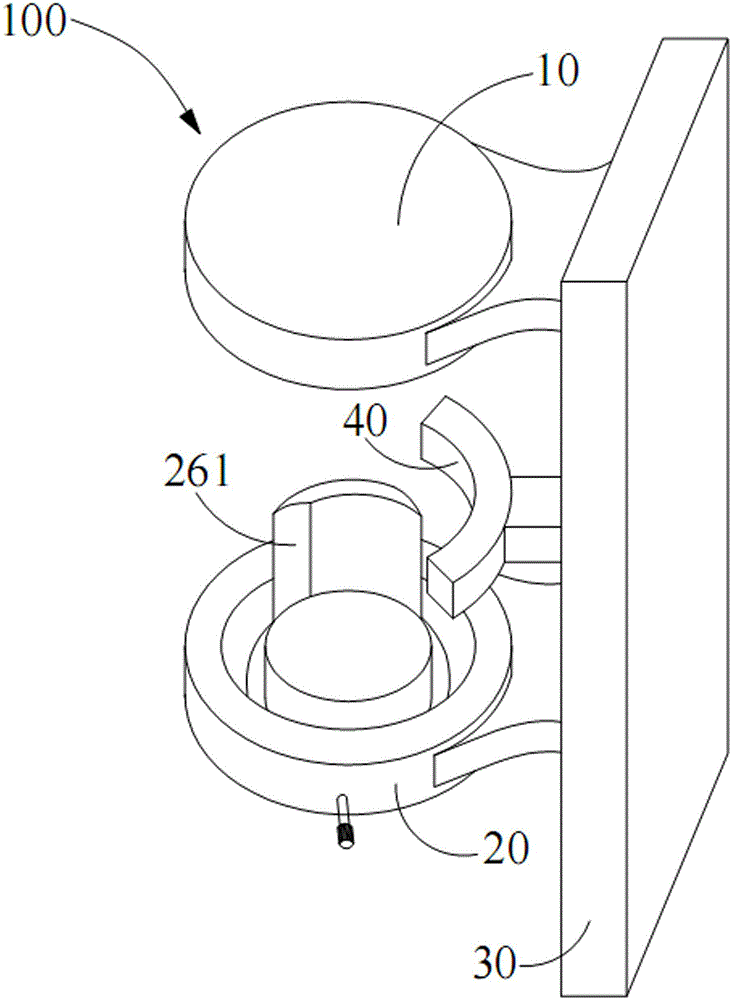

[0017] see Figure 1-3 , the collection tube fixing mechanism 100 shown in the preferred embodiment of the present invention includes a bracket 30, an upper fixing plate 10, a lower fixing plate 20 and a fitting 40, and the upper fixing plate 10, the lower fixing plate 20 and the fitting 40 are set on the same side of the bracket 30 .

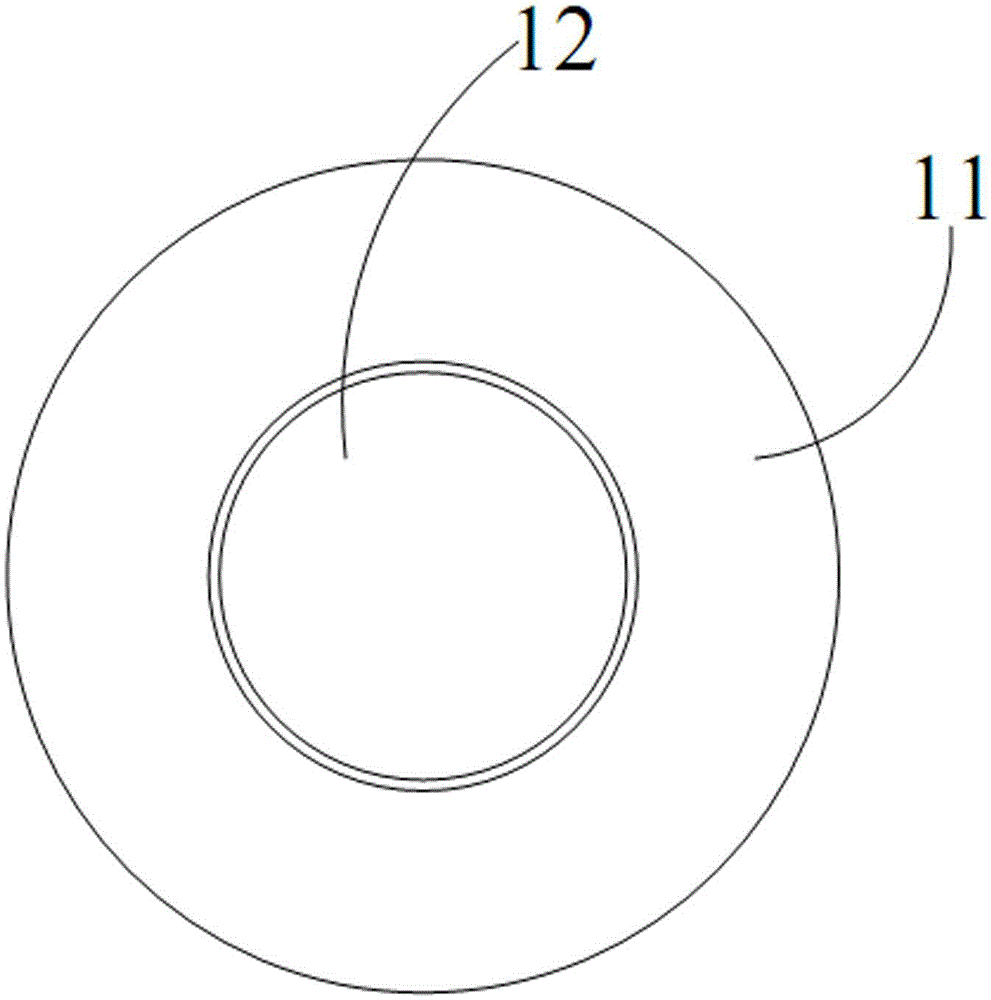

[0018] The upper fixing plate 10 includes a first body 11 and a first turntable 12 that can rotate relative to the first body 11 . The first body 11 is fixedly connected with the bracket 30 . One end of the first body 11 adjacent to the lower fixing plate 20 defines an accommodating cavity (not shown) for accommodating the first turntable 12 .

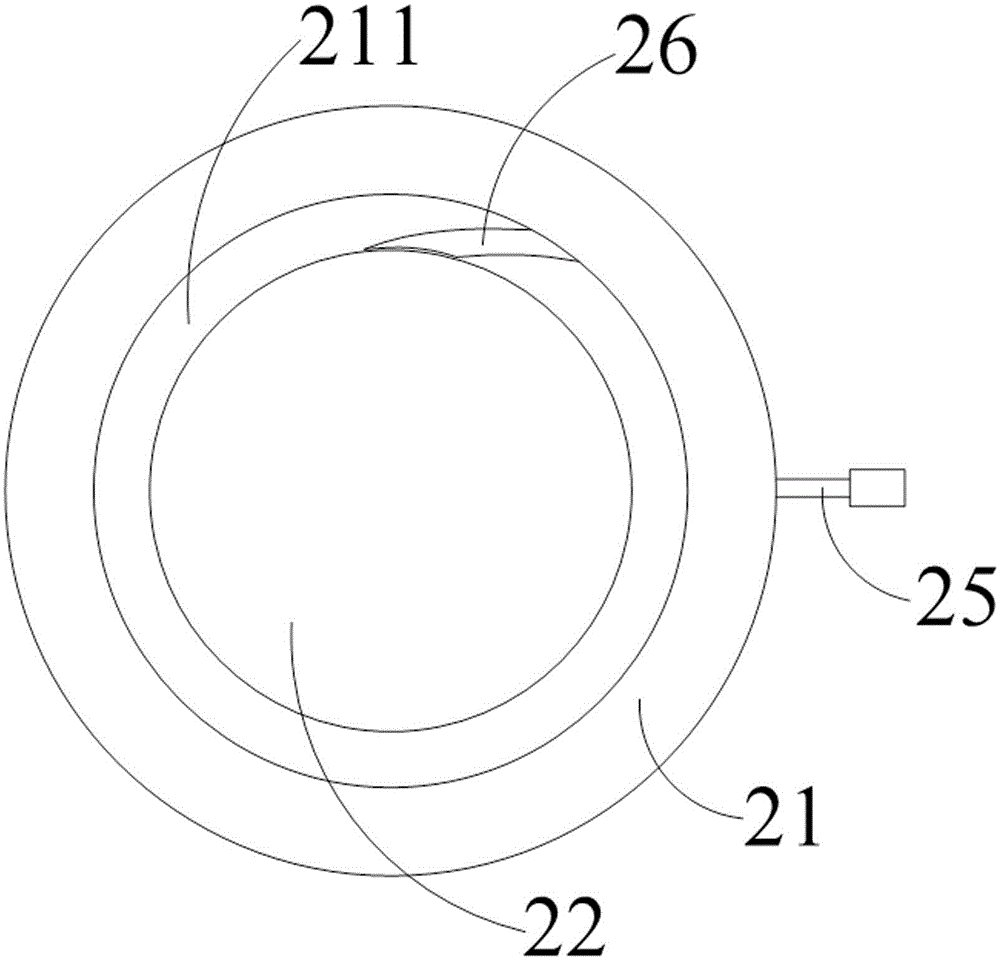

[0019] The lower fixing plate 20 includes a second body 21 , a second turntable 22 , a worm wheel, a worm screw, an operating handle 25 and an auxiliary adjusting member 26 .

[0020] The second body 21 can be raised and lowered relative to the first body 11 , and is slidably connected with the brack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com