Method for evaluating heat protection level of protective fabric and protective clothes

An evaluation method and thermal protection technology, applied in the direction of material thermal development, etc., can solve problems such as difficult results, different burn evaluation methods, and difficulty in effectively distinguishing the local thermal protection level of clothing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

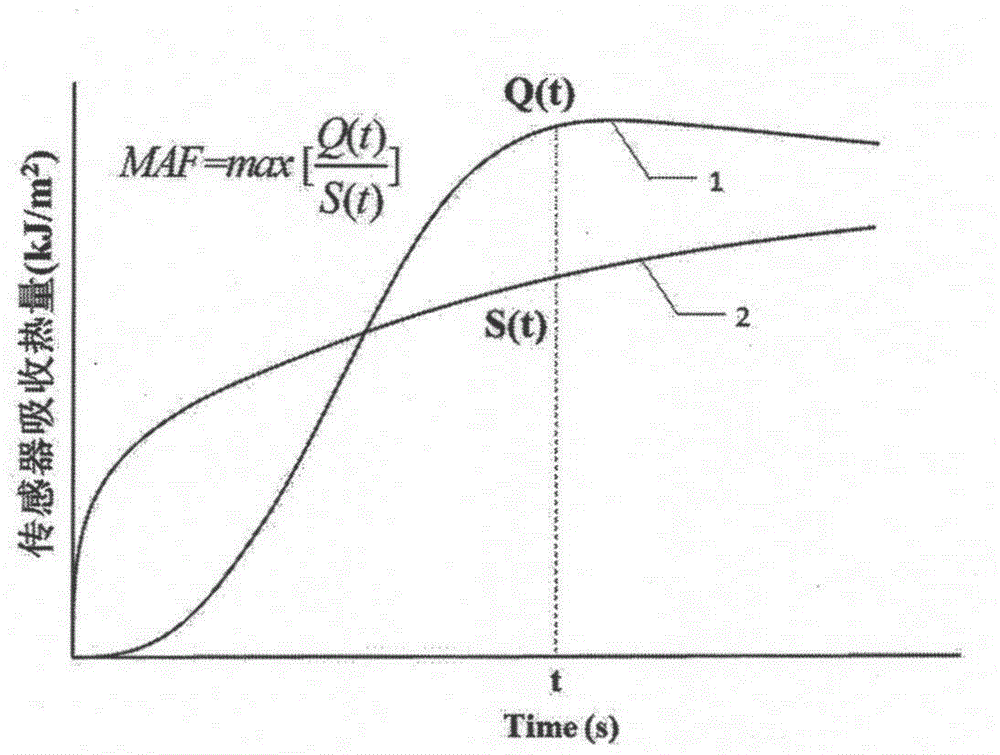

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] The thermal protection levels of the fabrics shown in Table 1 were evaluated using the present invention. The heat exposure time of the fabric is set to 4s, and the data collection time of the cooling stage after the heat exposure is set to 60s. The thermal protection level test of the fabric adopts a general-purpose fabric thermal protection performance tester. The system complies with ISO17492 and uses a copper sheet heat flow meter to collect data on the temperature of the back of the fabric.

[0065] Table 1. Basic properties of tested fabrics

[0066]

[0067] CF is conductive fiber; PSA is polysulfonamide fiber; FR is flame retardant.

[0068] The evaluation method of the thermal protection level of the protective fabric is:

[0069] Step 1: Before the experiment starts, according to the test standard ISO17492, place the thermal protection fabric on the fabric thermal protection performance tester, with the front of the fabric facing the simulated heat source...

Embodiment 2

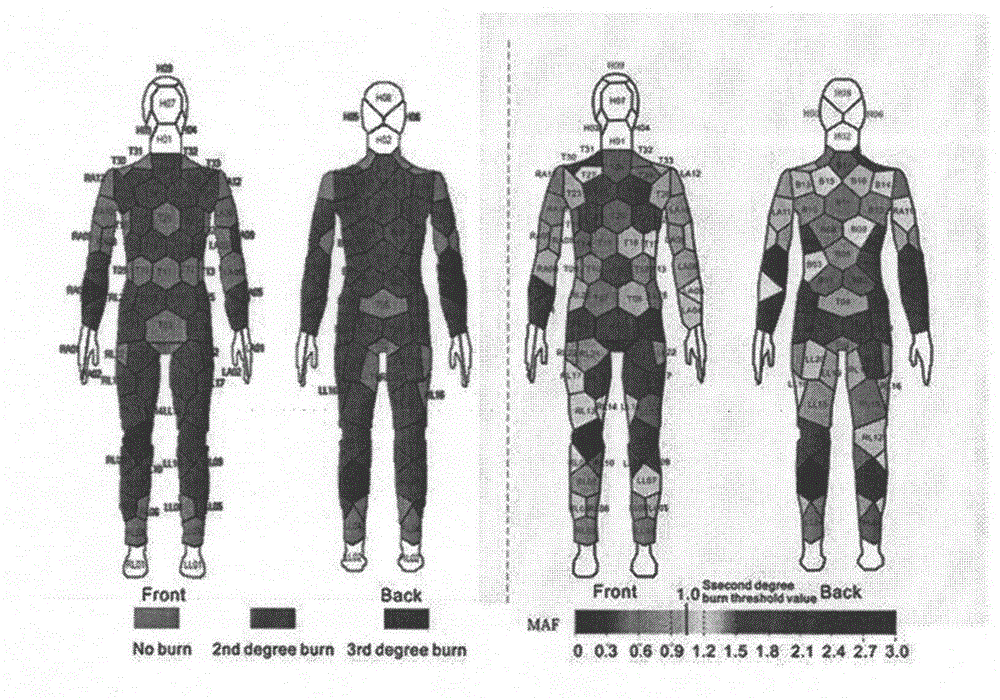

[0093] Garments made from the fabrics in Table 1, all of the same style and size, were evaluated according to the invention for their level of thermal protection. The same as the test procedure at the fabric level, the heat exposure time of the garment is set to 4s, and the cooling time after the heat exposure is set to 60s. The overall test of the clothing adopts the burning dummy test system, which complies with ISO13506 and uses 118 sensors on the surface of the dummy (since the head, hands and feet of the dummy are not covered by the clothing, these parts need to be removed) to test the dummy. The heat flux density of the table is collected.

[0094] The evaluation method for the thermal protection level of protective clothing adopts a burning dummy test system for testing the overall thermal protection performance of clothing. The system complies with ISO13506, and is characterized in that it includes:

[0095] Step 1: Before the experiment starts, according to the test ...

Embodiment 3

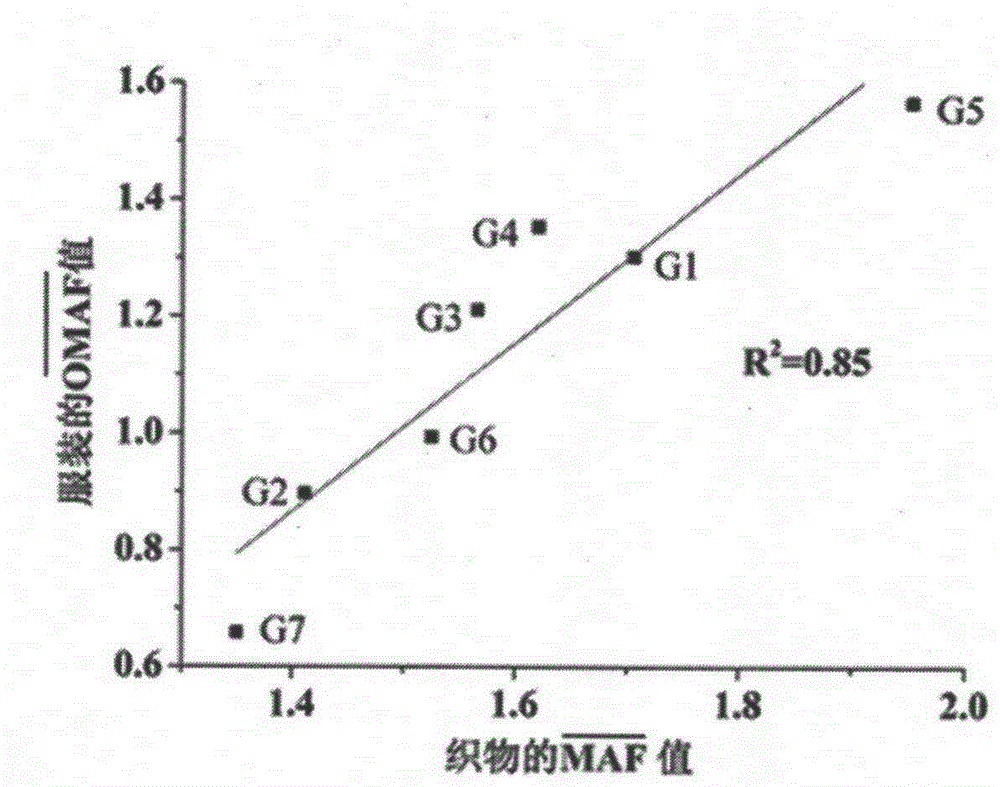

[0123] From Example 1 and Example 2, it can be seen that the heat exposure time and cooling time of fabric and clothing are the same, and the evaluation index of fabric and clothing thermal protection level is also consistent, so the test results of fabric level and clothing level can be compared direct comparison, the comparison results are as follows image 3 shown. from image 3 It can be seen that the fabric value and clothing The correlation coefficient of the value is 0.85, which proves that there is a strong correlation between the two. Generally speaking, the better the thermal protection level of the fabric, the better the thermal protection level of the corresponding clothing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com