A high-efficiency condenser tube bundle defogging device and its application

A technology of demisting device and condenser tube, which is applied in steam condensation, chemical instruments and methods, separation methods, etc., can solve the problems of difficulty in limit particle size, high working speed, etc., achieve improved effect, simple structure, and save water resources Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Hereinafter, the present invention will be further described in detail by taking the embodiment of the accompanying drawings as an example. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

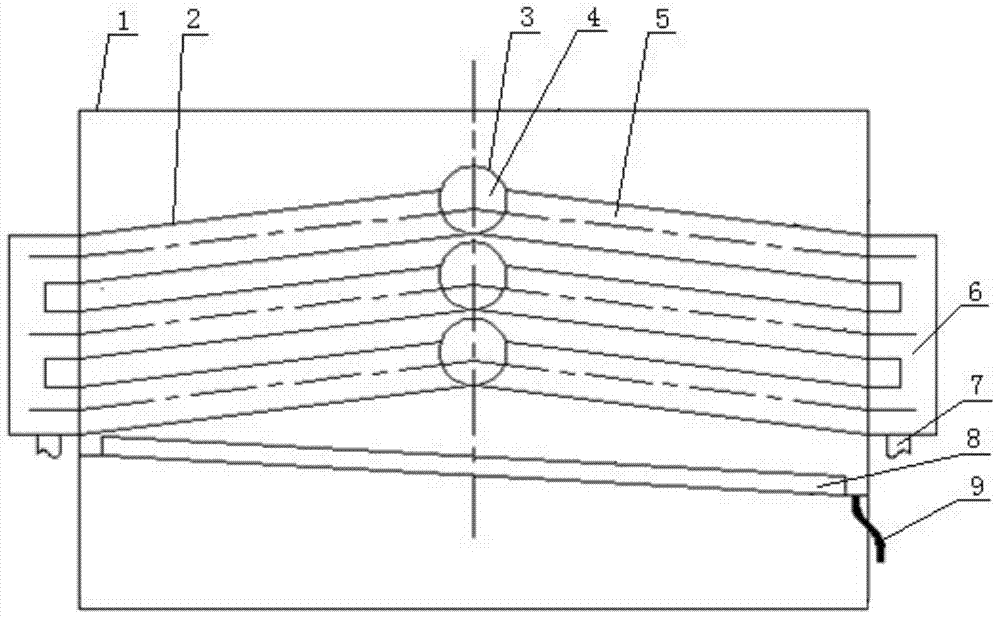

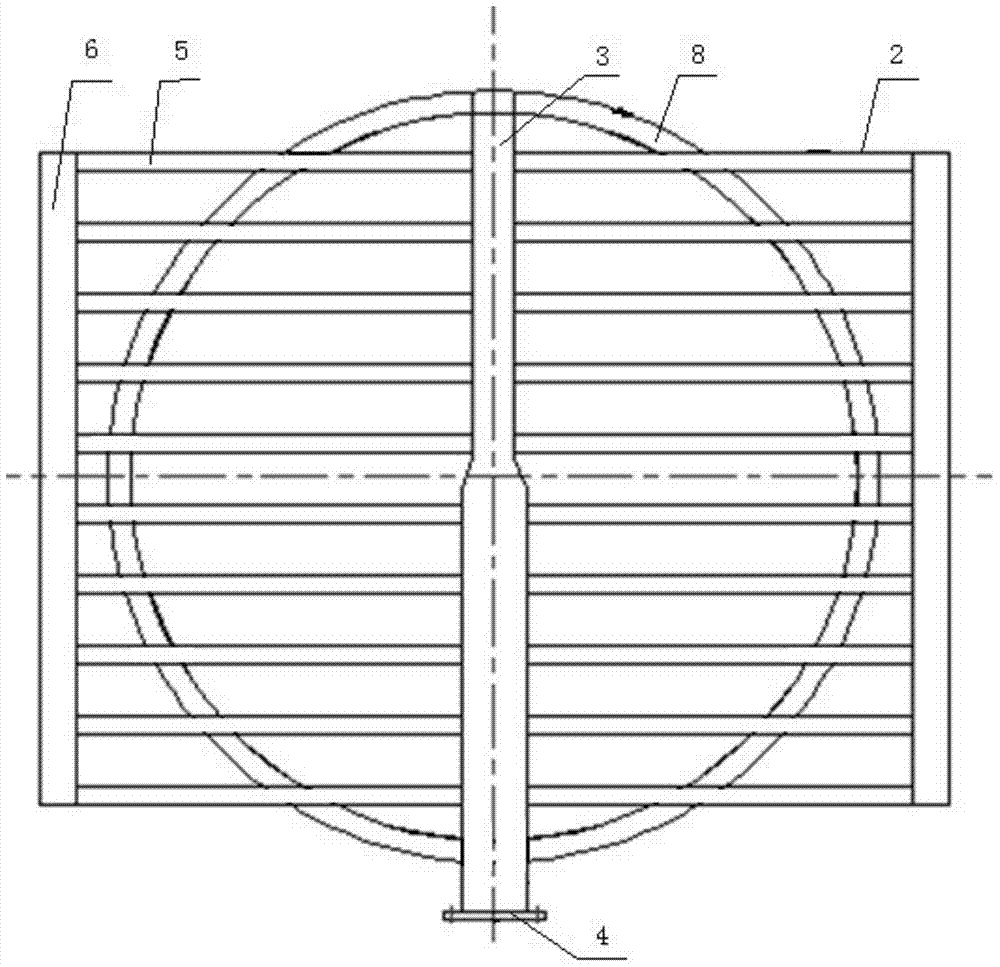

[0030] A high-efficiency condensing tube bundle demisting device, such as figure 1 and figure 2 As shown, the device includes multiple sets of upper and lower condensation tube bundle devices 2, water inlets 4, water outlets 7, condensed water collectors 8, and condensed water drains 9 arranged in parallel and spaced intervals on the tower 1. The bottommost A condensate collecting device is installed on the inner wall of the tower below the condensing tube bundle device to collect the flue gas condensed water condensed by the condensing tube bundle device in the tower. , the other end of the condensed water drain extends to the outside of the tower to discharge the flue gas condensed water in the conde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com