High-strength and low-rebound refractory spray coating and preparation method thereof

A low-rebound, high-strength technology, applied in the field of refractory materials, can solve the problems of high rebound rate and low strength, and achieve the effects of low rebound rate, good construction performance, and improved uniformity and activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

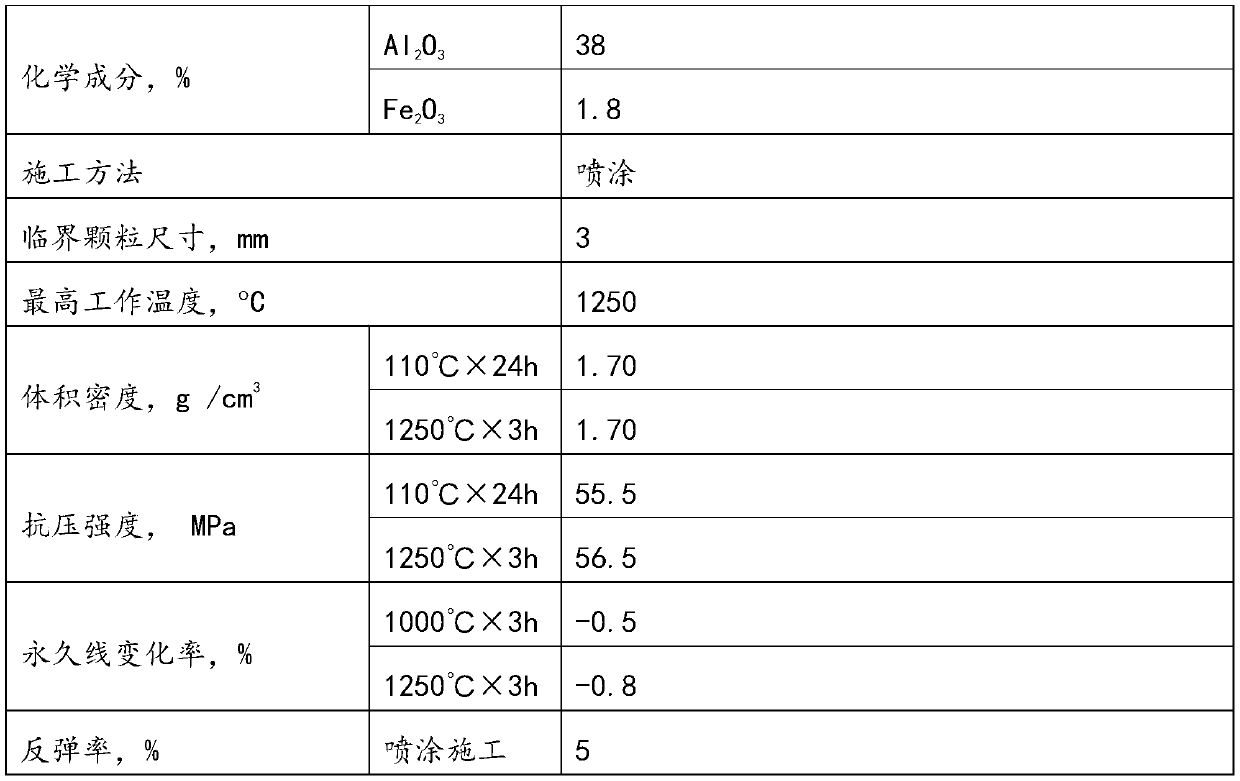

Embodiment 1

[0022] A high-strength, low-rebound fire-resistant spray coating, using the following raw materials and weight percentages: 35% coke gemstones, 20% porous mullite, 8% expanded vermiculite, 5% floating beads, 32% composite binder .

[0023] Burnt Gem Al 2 o 3 Content 40%, bulk density 2.32g / cm 3 , particle size 3 ~ 1.2mm.

[0024] Porous mullite Al 2 o 3 Content 40%, bulk density 1.2g / cm 3 , Particle size 1.2 ~ 0.3mm.

[0025] Expanded vermiculite is calcined at 850-880°C, with a bulk density of 160kg / m 3 ,Al 2 o 3 The content is 42%, and the particle size is less than 0.3mm.

[0026] Bead Al 2 o 3 Content 40%, SiO 2 Content 55%, Fe 2 o 3 Content 2.5%, R 2 The O content is 1.2%, and the particle size is less than 200 μm.

[0027] The composite binder uses 20% Portland cement, 30% CA-60 aluminate cement, 20% CA-80 aluminate cement, and 12% active SiO 2 Micropowder, 15% of 200 mesh raw clay powder, 1.5% of NaOH, and 1.5% of triethanolamine are prepared by co-gri...

Embodiment 2

[0036] A high-strength, low-rebound fire-resistant spray coating, using the following raw materials and weight percentages: 30% coke gemstones, 25% porous mullite, 7% expanded vermiculite, 6% floating beads, 32% composite binder .

[0037] Burnt Gem Al 2 o 3 Content 36%, bulk density 2.35g / cm 3 , particle size 3 ~ 1.2mm.

[0038] Porous mullite Al 2 o 3 Content 36%, bulk density 1.15g / cm 3 , Particle size 1.2 ~ 0.3mm.

[0039] Expanded vermiculite is calcined at 860-880°C, with a bulk density of 120kg / m 3 ,Al 2 o 3 42%, the particle size is less than 0.3mm.

[0040] Bead Al 2 o 3 Content 35%, SiO 2 Content 60%, Fe 2 o 3 Content 3.5%, R 2 The O content is 1.2%, and the particle size is less than 200 μm.

[0041] The composite binder uses 25% Portland cement, 30% CA-60 aluminate cement, 20% CA-80 aluminate cement, and 8% active SiO 2 Micropowder, 15% of 200 mesh raw pottery clay powder, 1.0% of NaOH, 1.0% of triethanolamine, was prepared by co-grinding with a h...

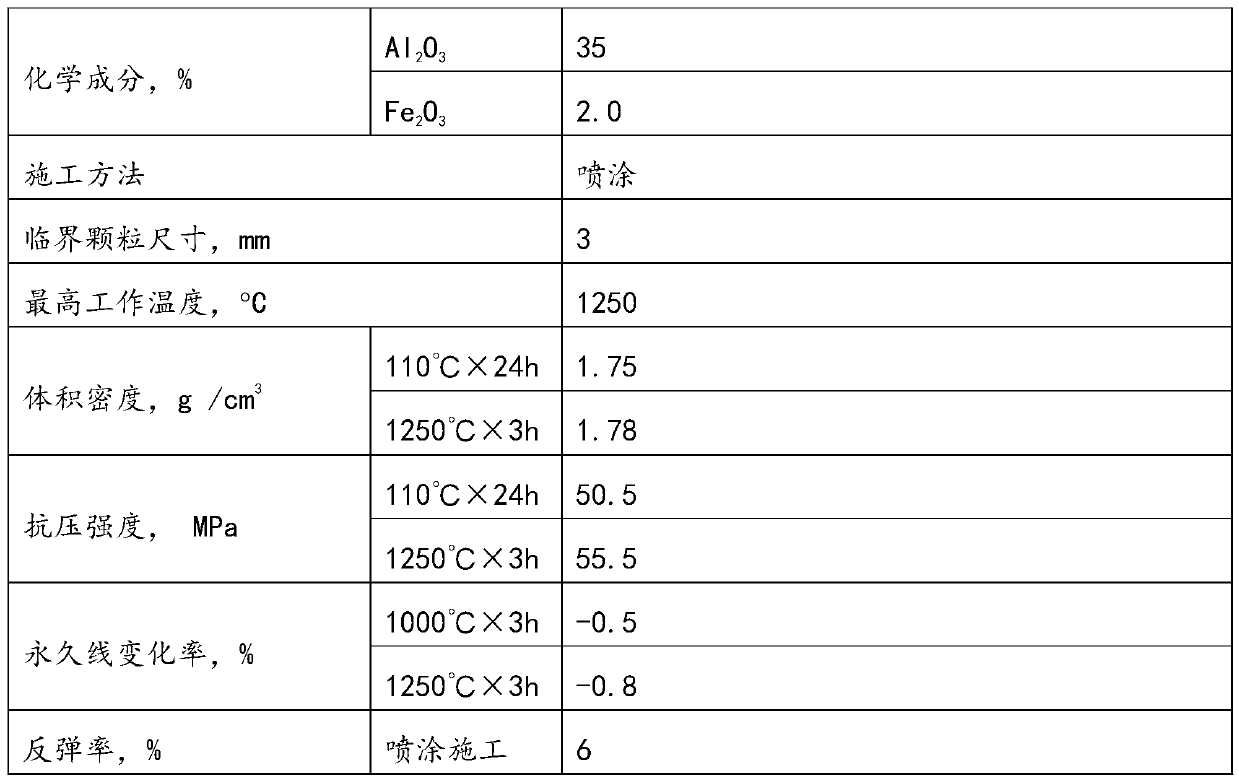

Embodiment 3

[0050] A high-strength, low-rebound fire-resistant spray coating, using the following raw materials and weight percentages: 33% coke gemstones, 23% porous mullite, 8% expanded vermiculite, 6% floating beads, 30% composite binder .

[0051] Burnt Gem Al 2 o 3 Content 38%, bulk density 2.31g / cm 3 , particle size 3 ~ 1.2mm.

[0052] Porous mullite Al 2 o 3 Content 38%, bulk density 1.18g / cm 3 , Particle size 1.2 ~ 0.3mm.

[0053] Expanded vermiculite is calcined at 860-880°C, with a bulk density of 130kg / m 3 ,Al 2 o 3 The content is 41%, and the particle size is less than 0.3mm.

[0054] Bead Al 2 o 3 Content 36%, SiO 2 Content 57%, Fe 2 o 3 Content 2.0%, R 2 The O content is 1.0%, and the particle size is less than 200 μm.

[0055] The composite binder uses 22% Portland cement, 31.6% CA-60 aluminate cement, 21% CA-80 aluminate cement, and 8% active SiO 2 Micropowder, 15% of 200 mesh raw pottery clay powder, 1.2% of NaOH, 1.2% of triethanolamine, was prepared by...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com