Welding wire winding machine protecting device

A technology of protective device and layer winding machine, which is applied in the directions of transportation and packaging, transportation of filamentous materials, and thin material handling, etc., can solve the problems of wire breakage, hidden dangers of operator safety, etc., and achieve the effect of convenient finishing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0026] The present invention will be described in detail below with reference to the accompanying drawings and examples.

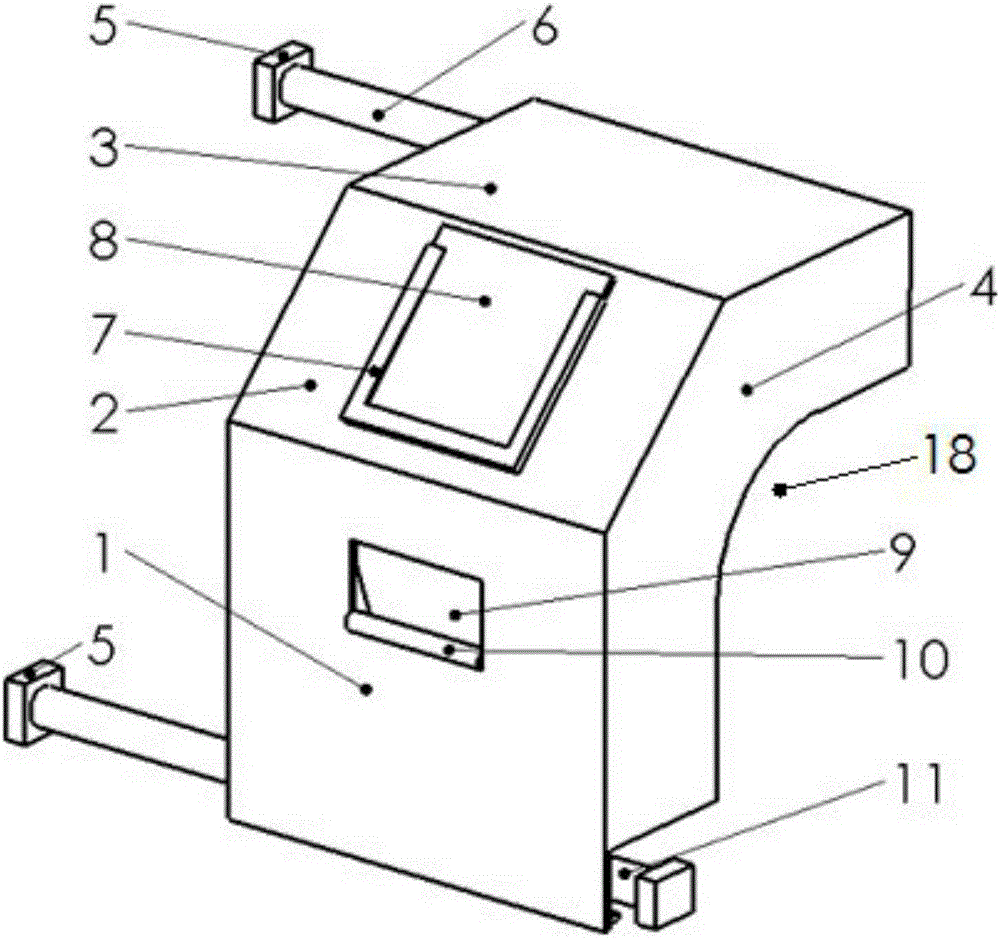

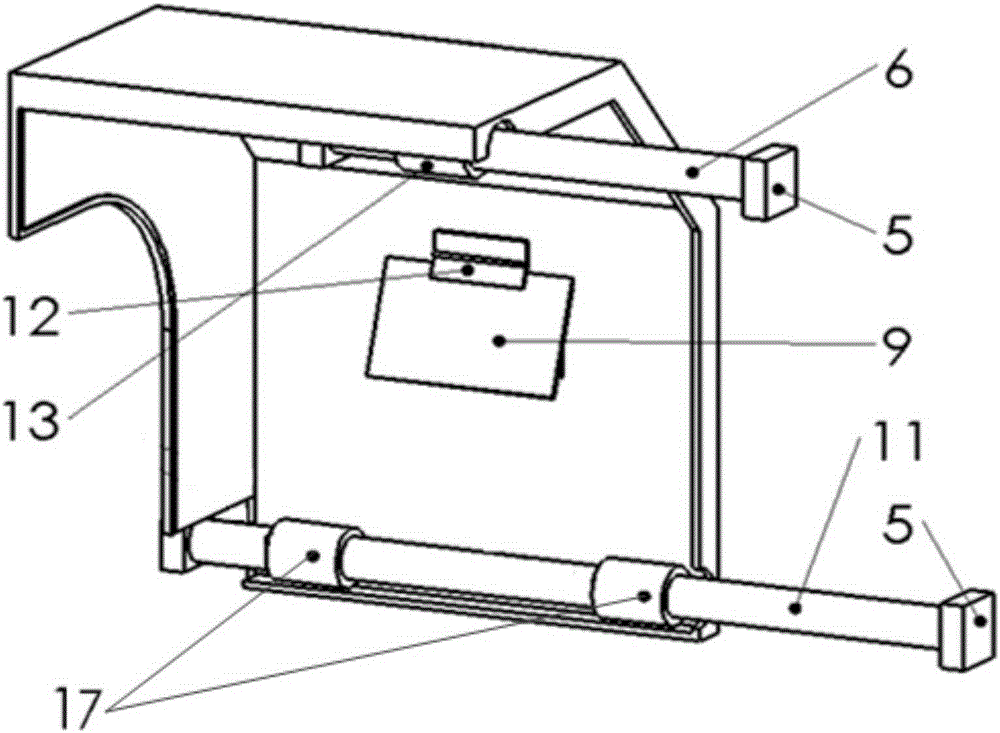

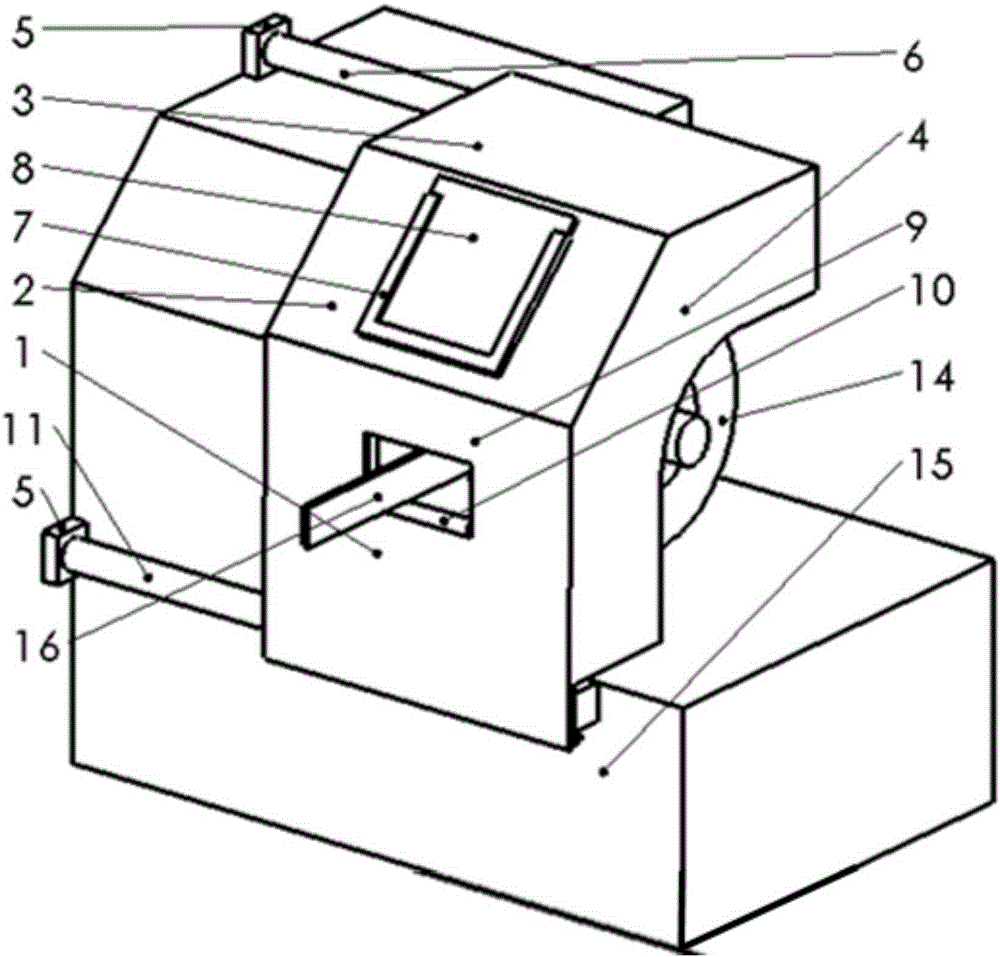

[0027] Such as Figure 1-5 , the present invention proposes a protective device for welding wire layer winding machine, including a protective cover and a slide rail, the slide rail is fixed on the equipment, the protective cover is slidably connected with the slide rail, the protective cover is provided with a window, and the protective cover is also provided with an operation hole , The position of the operating hole on the inner surface of the protective cover is provided with a movable plate 9, and the movable plate 9 is rotationally connected with the protective cover.

[0028] Above-mentioned slide rail comprises a long polished rod 11 and a short polished rod 6.

[0029] The lon...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap