Boiler sewage system based on cloud computing and sewage quality control

A technology for boilers and controllers, which is applied to boiler cleaning devices and indications of boiler working conditions. It can solve problems such as inability to flexibly adjust control procedures and parameters, and achieve the effects of saving heat exchange, preventing waste of heat energy, and optimizing the structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0032] In this article, if there is no special explanation, when it comes to formulas, " / " means division, and "×" and "*" mean multiplication.

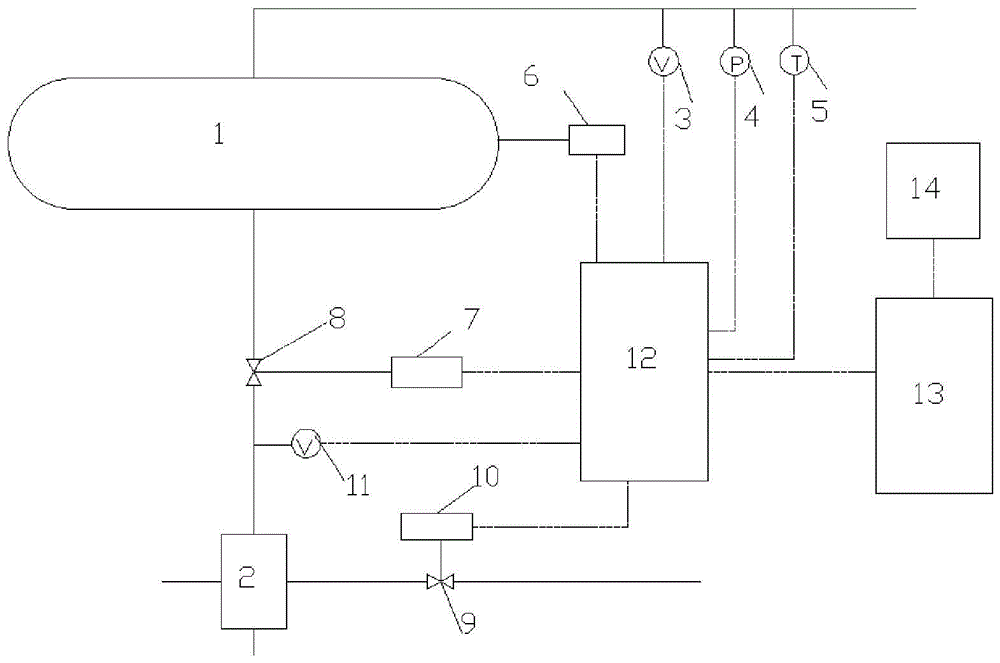

[0033] A boiler thermodynamic system, the boiler thermodynamic system includes at least one boiler for generating steam, and the boiler is in data connection with a monitoring and diagnosis controller 12 so as to monitor the operation of the boiler. The monitoring and diagnosis controller 12 is data-connected with the cloud server 13 so as to transmit the monitored data to the cloud server. The cloud server 13 is connected with the client 14, and the client 14 can obtain various monitoring information through the cloud server.

[0034] Advantageously, the client can input data to control the operation of the boiler system.

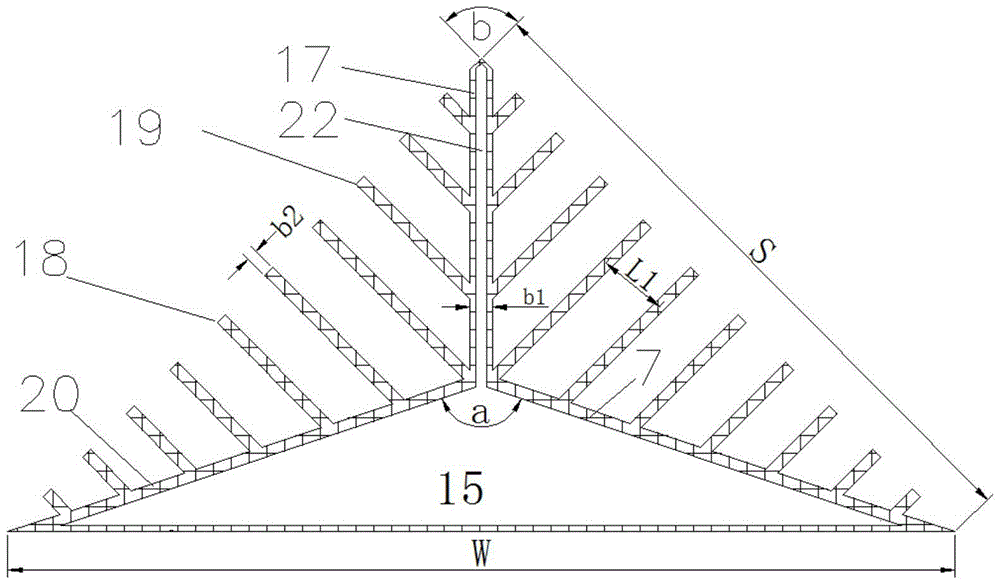

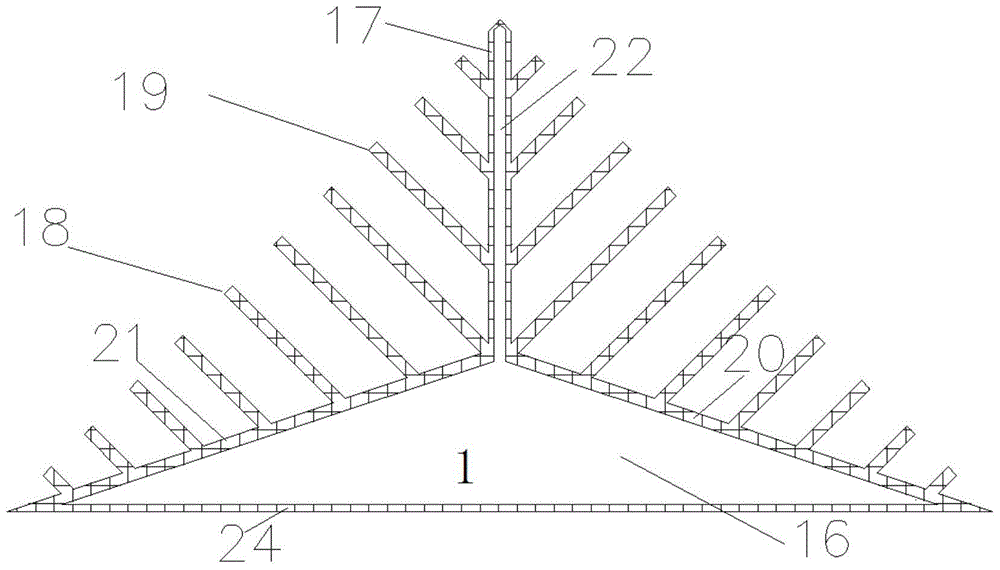

[0035] Such as figure 1 As shown, the boiler includes an automatic con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com