Water-swirl gas direct injection type pesticide spraying device

A direct air injection and pesticide technology, which is applied in the field of water cyclone air direct injection pesticide spraying device, can solve the problems of small shooting range and insufficient spraying power, and achieve the effect of low cost, high quality spraying and long shooting range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Now in conjunction with accompanying drawing, the present invention is described in further detail.

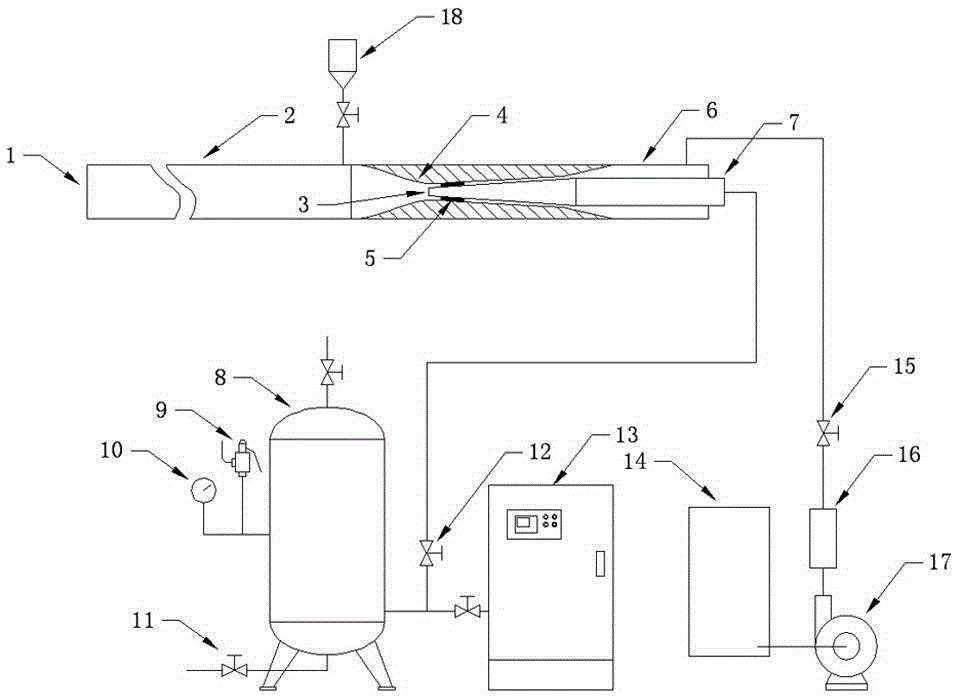

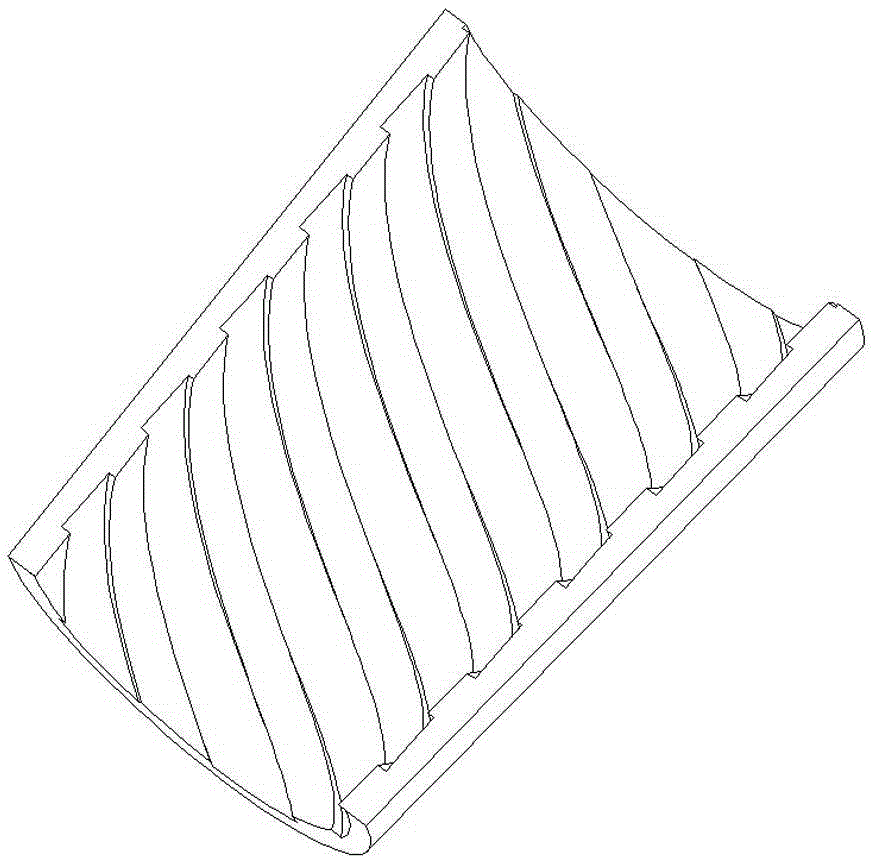

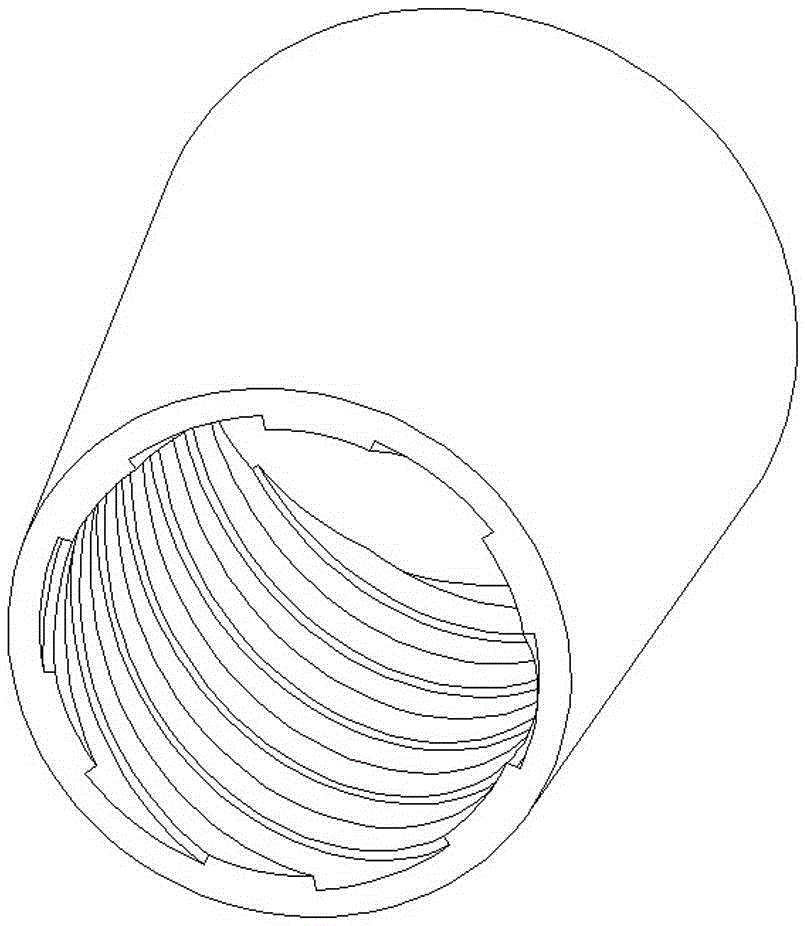

[0022] Such as figure 1 , figure 2 and image 3 The shown water cyclone direct injection pesticide spraying device includes an outer pipe 6 and a central pipe 7, the outer pipe 6 is connected to a water tank 14, the water tank 14 provides water to enter the outer pipe 6, the central pipe 7 is connected to a compressed air storage tank 8, and the compressed air The storage tank 8 provides pressurized gas to enter the central pipe 7; the outer pipe 6 and the central pipe 7 are jacketed structures, the front end of the central pipe 7 is a gas nozzle 3, and the compressed air in the central pipe 7 is sprayed directly from the back to the front into the Rafal surface Expansion chamber 4; the taper part of the central pipe 7 is non-full-contact coaxially embedded in the outer pipe 6, and the inner diversion section of the outer pipe has a change process of shrinking and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com