Detection device for intake resistance of small-flow air filer of universal machine

A technology for air intake resistance and testing equipment, which is used in the testing of machine/structural components, testing of mechanical components, instruments, etc. It can solve the problems of insufficient detection accuracy, low data consistency, and small size, and achieve accurate test values. , convenient air source, high consistency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

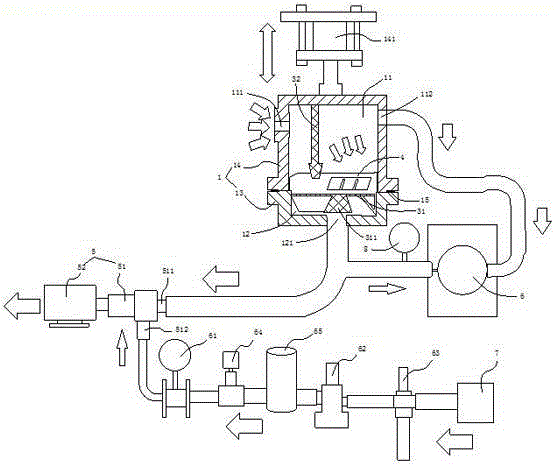

[0018] Such as figure 1 As shown in the figure, a detection device for air intake resistance of a general-purpose small-flow air filter includes a sealing inspection tool 1, and the sealing inspection tool 1 is provided with a fixing device for positioning the air filter 2 to be tested, and the air filter 4 to be tested is The inner cavity of the entire sealing inspection tool 1 can be divided into an air intake chamber 11 and an exhaust chamber 12, wherein the upper sides of the air intake chamber 11 are respectively provided with an air inlet 111 and a side air outlet 112, and the bottom of the exhaust chamber 12 is provided with Next to the exhaust port 121, the exhaust port 121 is connected to the negative pressure air source 5 through a pipeline, and the side air outlet 112 is connected to the pipeline of the exhaust port 121 after being connected to the differential pressure gauge 6 through a pipeline.

[0019] In this embodiment, the entire sealing inspection tool 1 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com