A micro-laser based on a side-polished optical fiber as a carrier and a transmission channel, its preparation method and application

A micro-laser and transmission channel technology, applied in the direction of semiconductor lasers, lasers, laser components, etc., can solve the problems of device instability, limitations, laser coupling output fiber integration problems, etc., achieve stable performance, simple preparation methods, and promote Applied effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

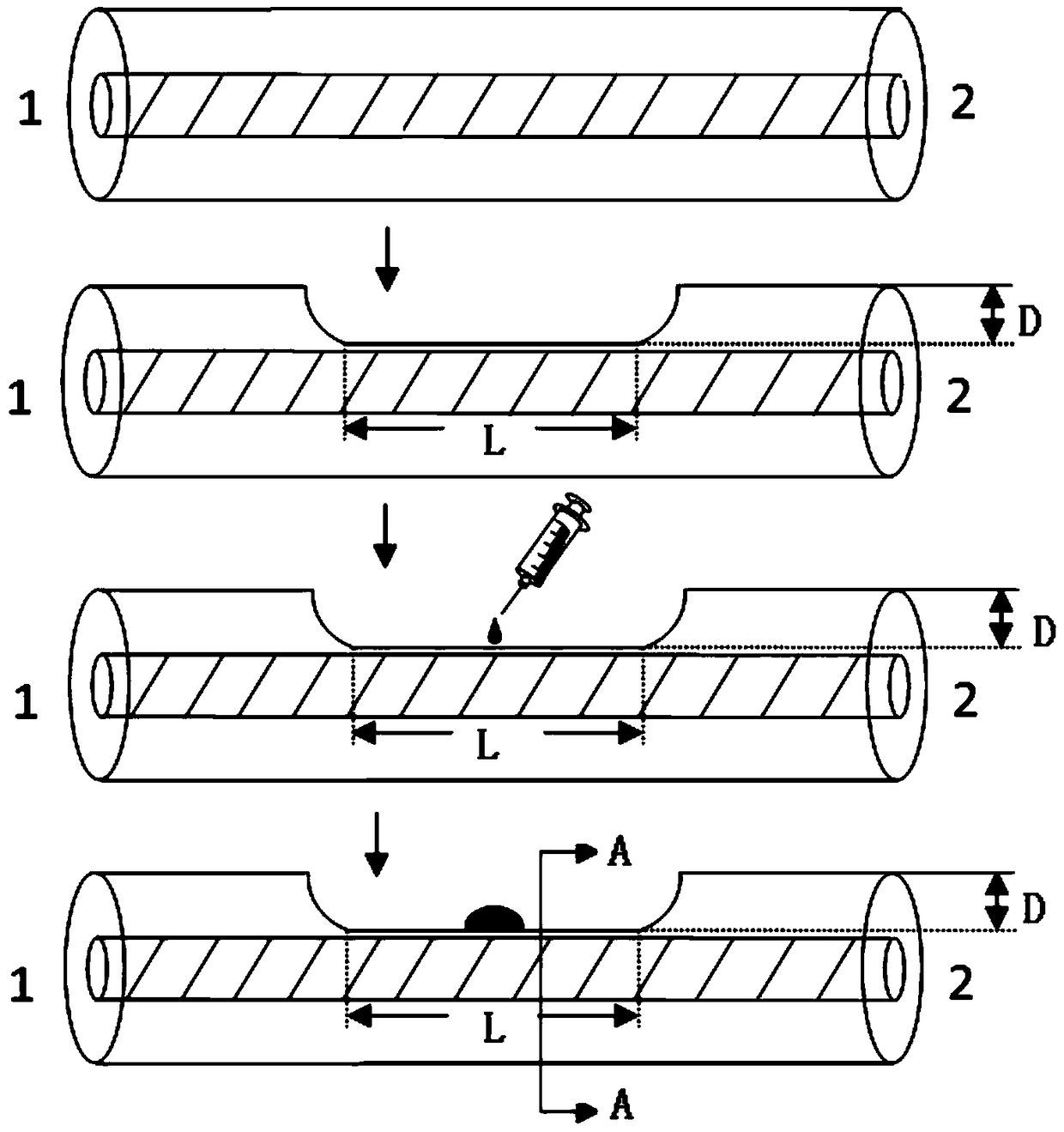

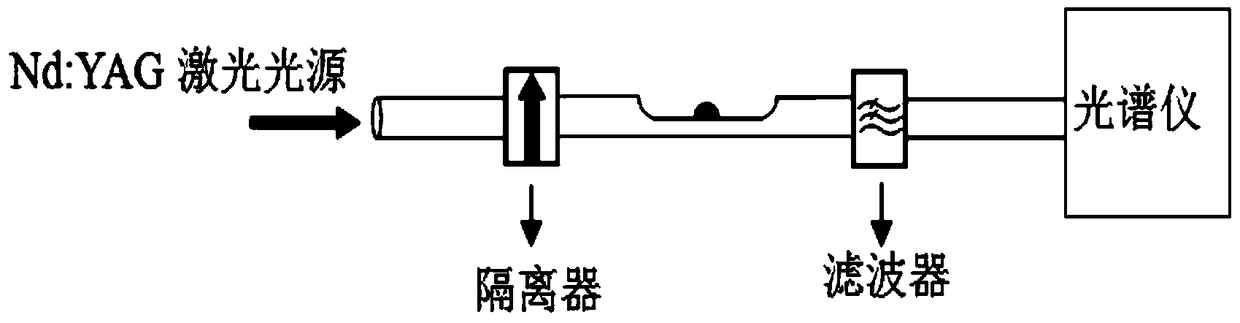

[0032] One, as figure 1 The steps shown are to prepare a microlaser based on a side-polished fiber as the carrier and delivery channel:

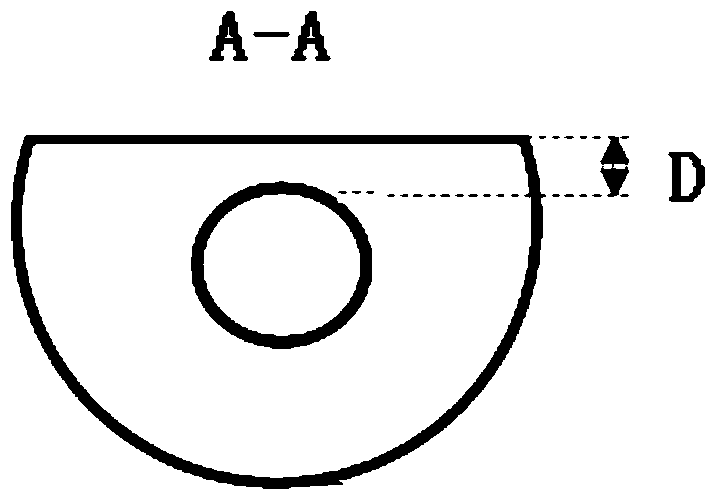

[0033] 1) Use the optical fiber side polishing device to polish a piece of circular ordinary optical fiber to prepare a side polished optical fiber. The length of the polishing area is 20 mm, the distance between the polishing surface and the fiber core interface is 4 μm, and the polishing area is The cross section is "D" shape, such as figure 2 As shown, the side-polished fiber has input port 1 and output port 2;

[0034] 2) After the side polishing optical fiber is prepared, in a vacuum environment, the polishing area is purified by using a plasma mixed with argon and oxygen to remove the organic pollutants on it;

[0035] 3) Using an ultraviolet ozone cleaning machine, at a temperature of 90 ℃, the polishing area is treated for 5 minutes, so that the polishing area has a certain degree of hydrophilicity, so as to prepare the WGM micro-...

Embodiment 2

[0042] 1. Press as figure 1 The following steps are used to prepare a microlaser based on a side-polished optical fiber as a carrier and a transmission channel:

[0043] 1) Use the optical fiber side polishing device to polish a section of circular ordinary optical fiber to prepare a side polished optical fiber. The length of the polishing area is 20 mm, and the distance between the polishing surface and the fiber core interface is 4 μm. The cross-section is "D" shape, such as figure 2 As shown, the side-polished fiber has an input port 1 and an output port 2;

[0044] 2) After the side-polished optical fiber is prepared, in a vacuum environment, a plasma mixed with argon and oxygen is used to purify the polishing area to remove the organic pollutants on it;

[0045] 3) Use an ultraviolet ozone cleaning machine to treat the polishing area for 5 minutes at a temperature of 90 ° C, so that the polishing area has a certain degree of hydrophilicity, so as to prepare micro-spher...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com