Pulse self-compression system and its coupling adjustment method based on kagome hollow-core photonic crystal fiber

A hollow photonic crystal and compression system technology, applied in the laser field, can solve problems such as inability to achieve flexible transmission and insufficient pulse width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The content of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0053] The output pulse width of existing femtosecond lasers is limited by the emission spectral width of the gain medium, and the output pulse width is generally in the range of hundreds of femtoseconds to one picosecond. In order to further compress the pulse width, high-energy ultra-short The pulse output meets the requirements of high-precision industrial cold processing under extremely harsh conditions for the pulse width of laser light sources and the requirements of high-energy physics for the limit pulse width. The present invention designs a pulse self-compressing system based on Kagome hollow photonic crystal fiber and its coupling adjustment method.

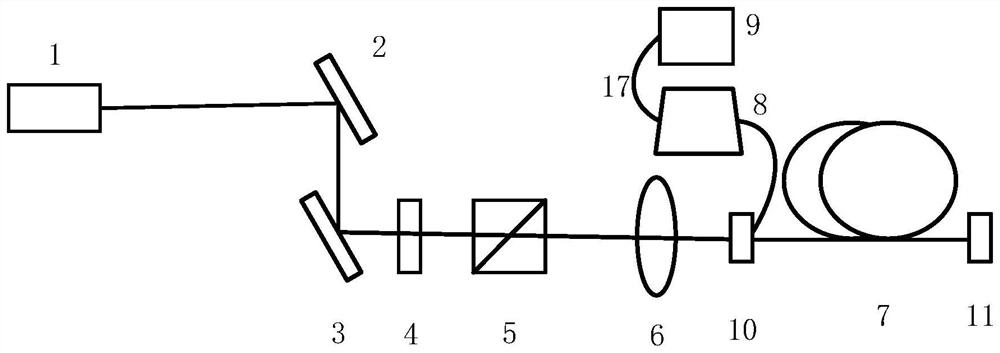

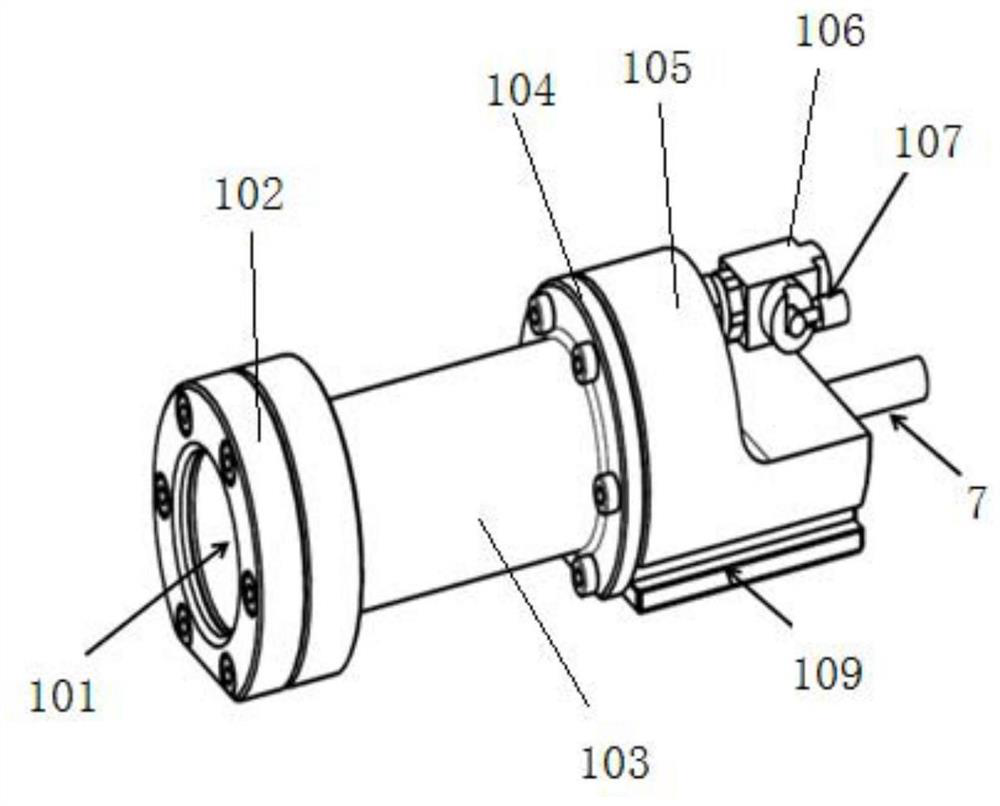

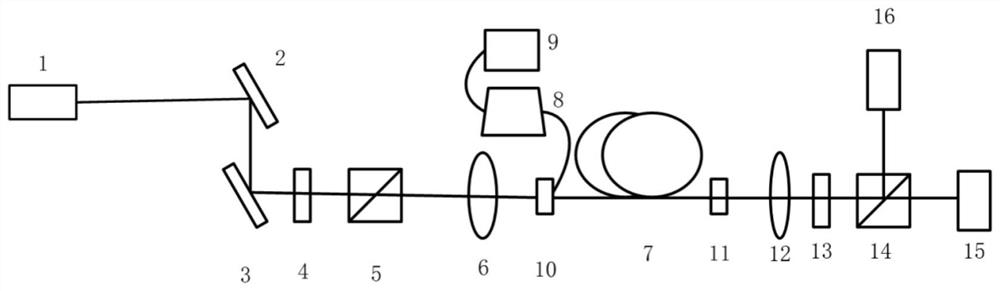

[0054] Such as figure 1 As shown, a pulse self-compression system based on the Kagome hollow-core photonic crystal fiber defines the outgoing direction of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com