The rubbing part of the intelligent shampoo robot presses down the positioning mechanism

A technology of positioning mechanism and robot, which is applied in hair or scalp washing devices, hairdressing equipment, clothing, etc. It can solve the problems that affect the smooth washing of hair, the inability to press the head, and the user's discomfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

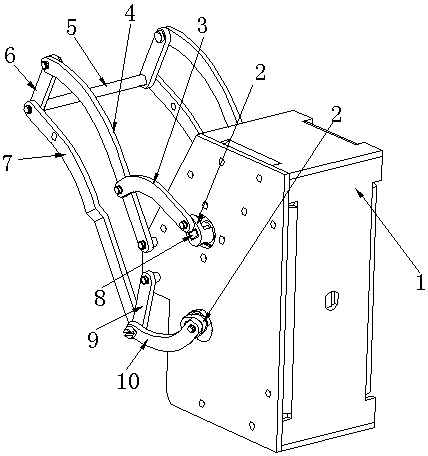

[0021] As shown in the figure, the pressing positioning mechanism of the rubbing part of the intelligent shampoo robot of the present invention is arranged on the shampooing robot, and is used for positioning the position of the pressing part of the rubbing part driven by the transmission part during the working process. The structure includes swinging Part 1, the transmission part and the kneading part, the swing head and the kneading part are located at both ends of the transmission part, the swing part 1 is provided with a power mechanism, the power mechanism provides power for the transmission part to make the transmission part move, and makes the kneading part perform corresponding action.

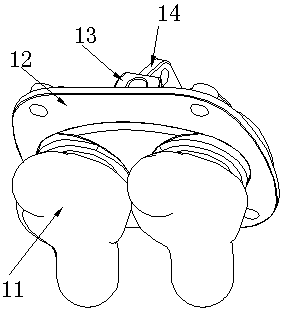

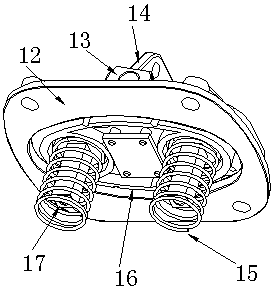

[0022] The structure of the kneading part includes a shell on which a number of kneading heads 11 protruding from the outer surface are movably arranged, and the kneading heads 11 are approximately in the shape of a V or V. A driving motor is provided in the housing, and the driving m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com