Valve-seat-free double-layer pipe straight-through type pressing closing valve and post-defecation anus cleaner

A double-tube, straight-through technology, applied in the direction of enema/irrigator, valve, infusion set, etc., can solve the problems of polluting the space, difficult to rinse, and manual water bladder irrigation can not rub the anus at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

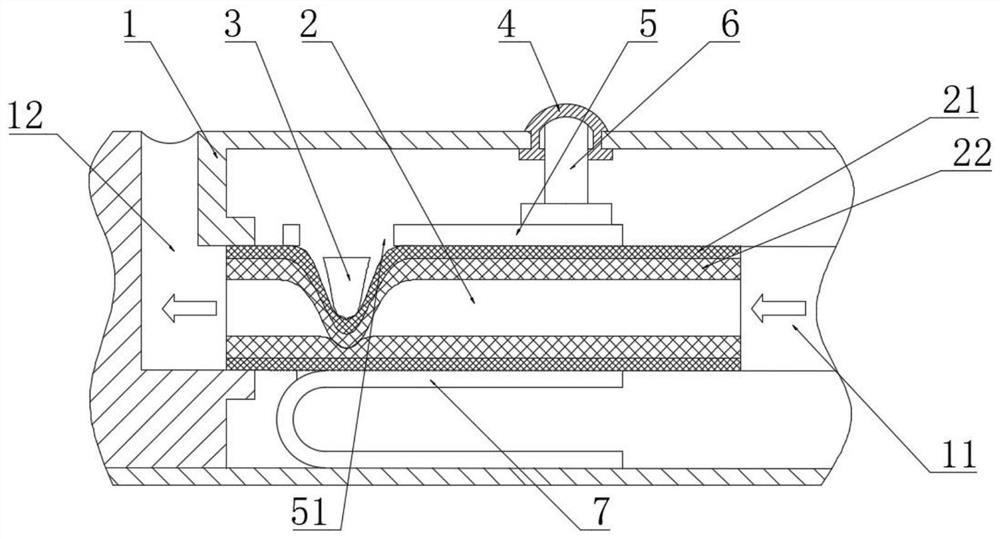

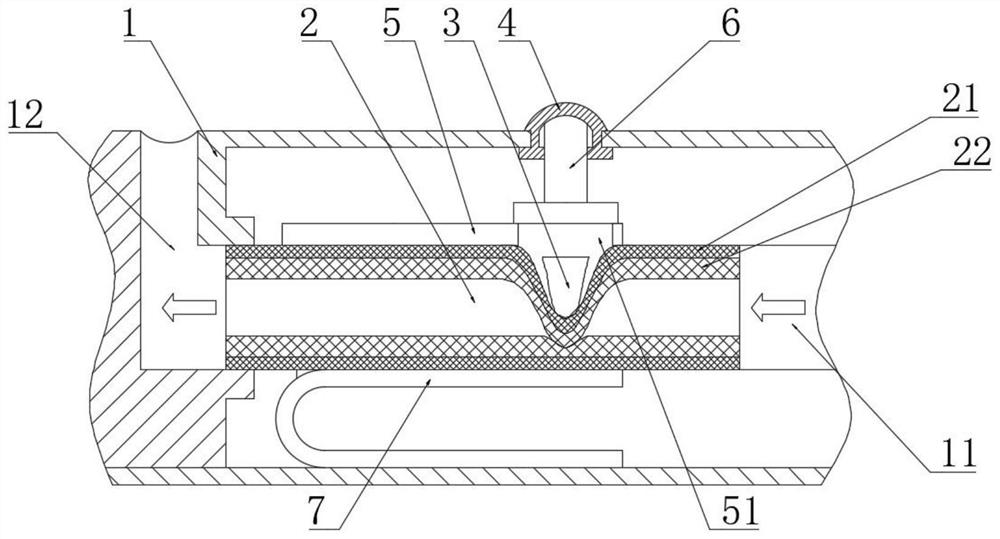

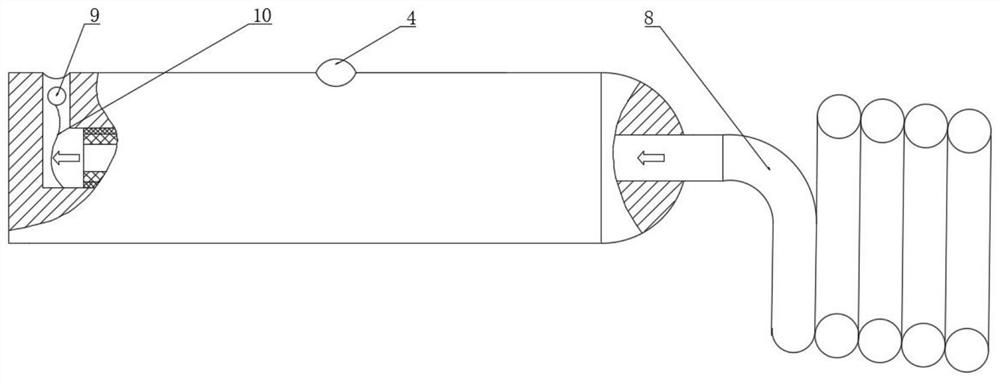

[0031] Embodiment 1: as Figure 1-2 As shown, an embodiment of a non-seat double-pipe straight-through push-close valve disclosed by the present invention includes:

[0032] Main body 1, double-layer pipe 2, horizontal gate 3, pipe groove 5, shrapnel 7;

[0033] The main body 1 is hollow inside and communicates with the outside world through the inlet port 11 and the outlet port 12. The inner lower end of the main body 1, the lower end of the pipe groove 5 is fixed on the upper end surface of the elastic sheet 7, the double-layer pipe 2 is nested inside the pipe groove 5, and the upper end surface of the pipe groove 5 has a gap 51, The horizontal gate 3 is fixed on the inner wall of the main body 1, and is inserted into the pipe groove 5 through the gap 51, and at the same time squeezes the double-layer pipe 2 and blocks the inlet port 11 and the The communication between the outlet ends 12, the other end of the upper end surface of the pipe groove 5 is also connected to one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com