Fork mechanism of forklift

A technology of forks and forklifts, applied in the direction of lifting devices, etc., to achieve the effects of flexible swing, expanded range and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

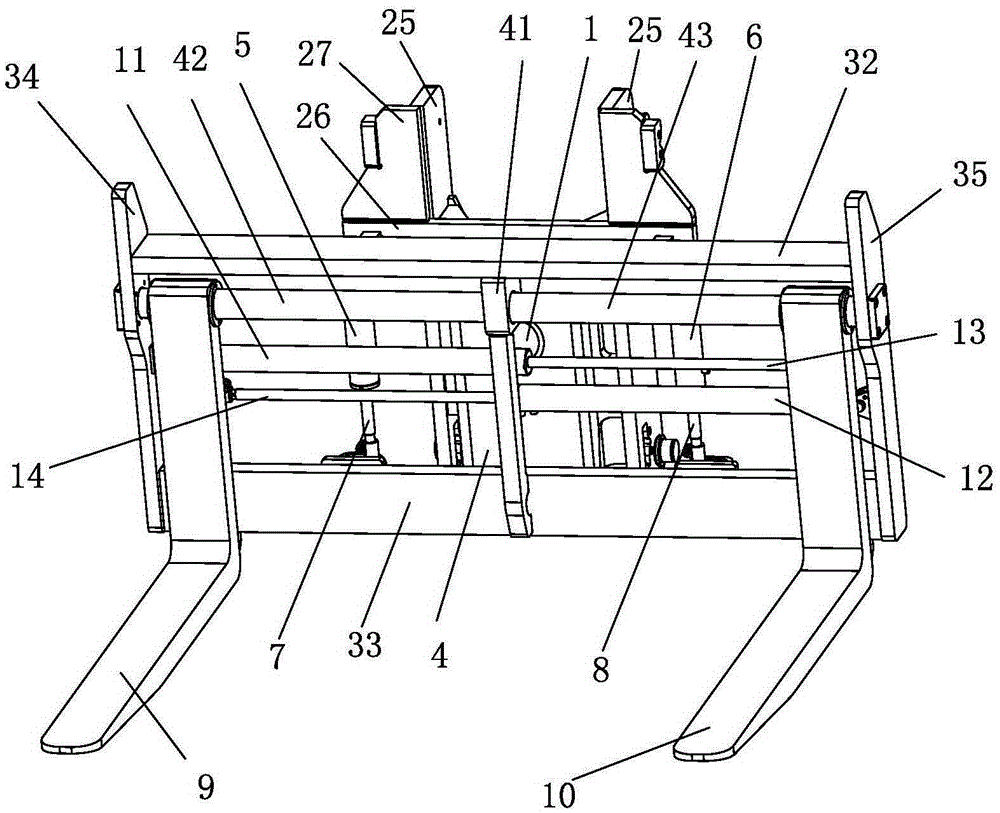

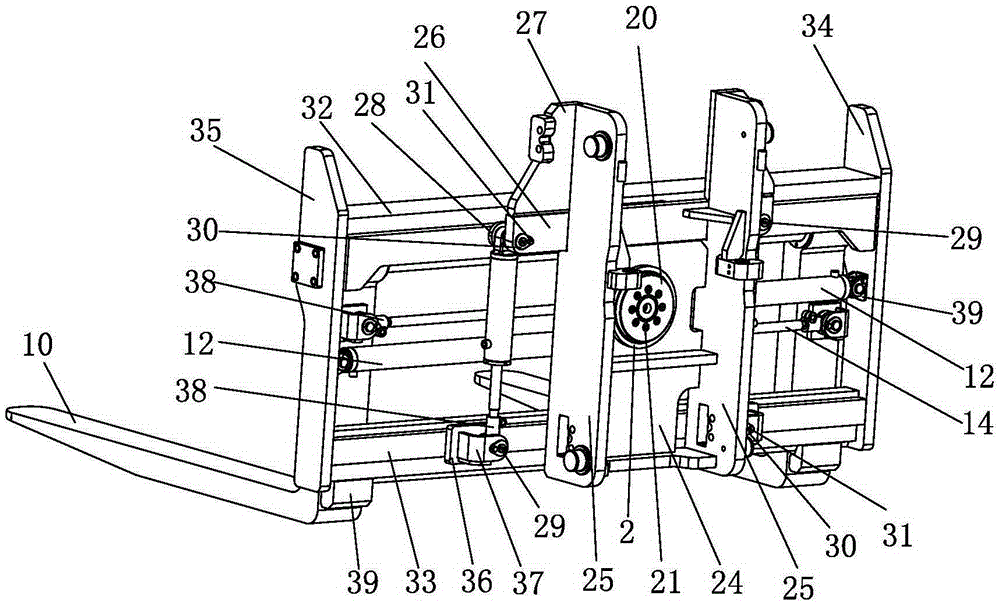

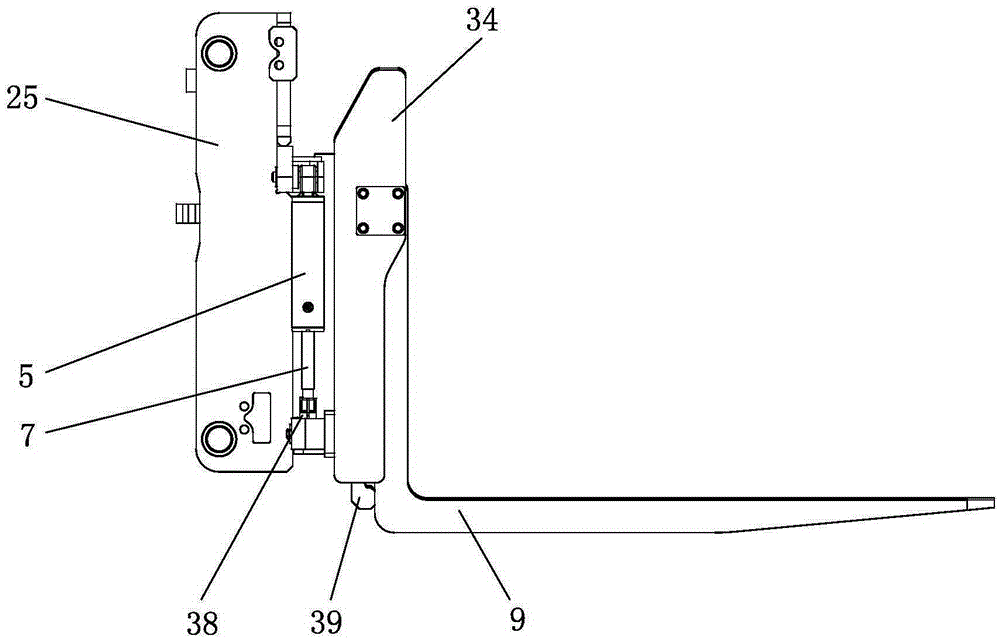

[0024] The present invention will be further described below with specific embodiment, see figure 1 -6:

[0025] A fork mechanism of a forklift, including a front fork frame and a rear fork frame, a rotating shaft 1 is arranged on the rear fork frame, a shaft sleeve 2 is covered on the rotating shaft shaft 1, and the shaft sleeve 2 is fixed on the rear fork frame , more than one bearing 3 is arranged between the rotating string shaft 1 and the shaft sleeve 2, and a string shaft fixing plate 4 is arranged at the front end of the rotating string shaft 1, and the string shaft fixing plate 4 swings together with the rotating string shaft 1, and the string shaft The front fork frame is fixed on the fixed plate 4, and the rear fork frame and the front fork frame on the left and right sides of the rotary string shaft 1 are respectively provided with left and right oil cylinders 5,6, left and right oil cylinders 5,6 piston rods 7, The expansion and contraction of 8 drives the front f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com