A high-performance film bulk acoustic resonator and its manufacturing method

A thin-film bulk acoustic wave and manufacturing method technology, applied in the direction of impedance network, electrical components, etc., can solve the problems of poor growth structure of the lower electrode 3, influence of FBAR frequency, and difficult process, so as to prevent device performance and long-term reliability, and improve Open circuit impedance, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

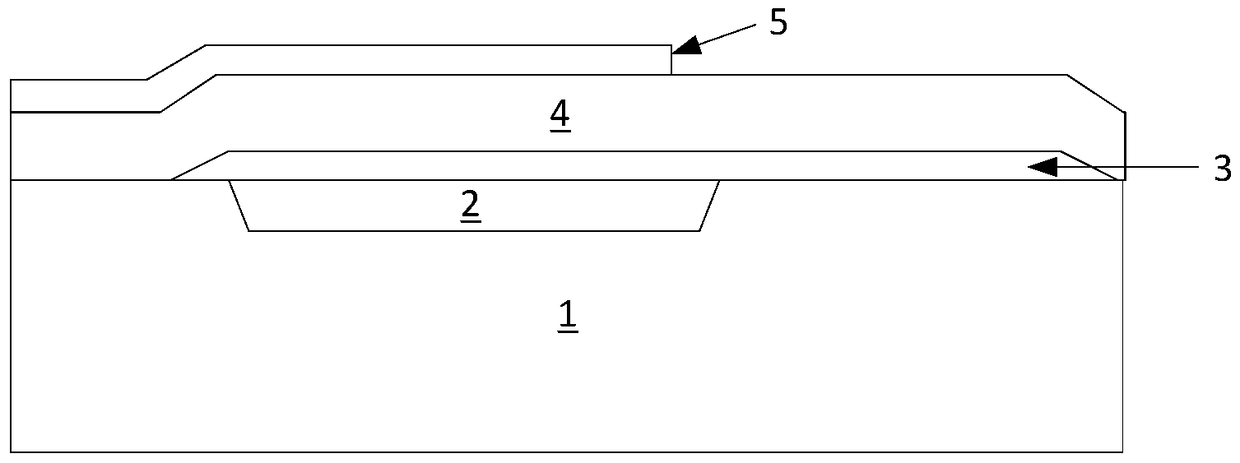

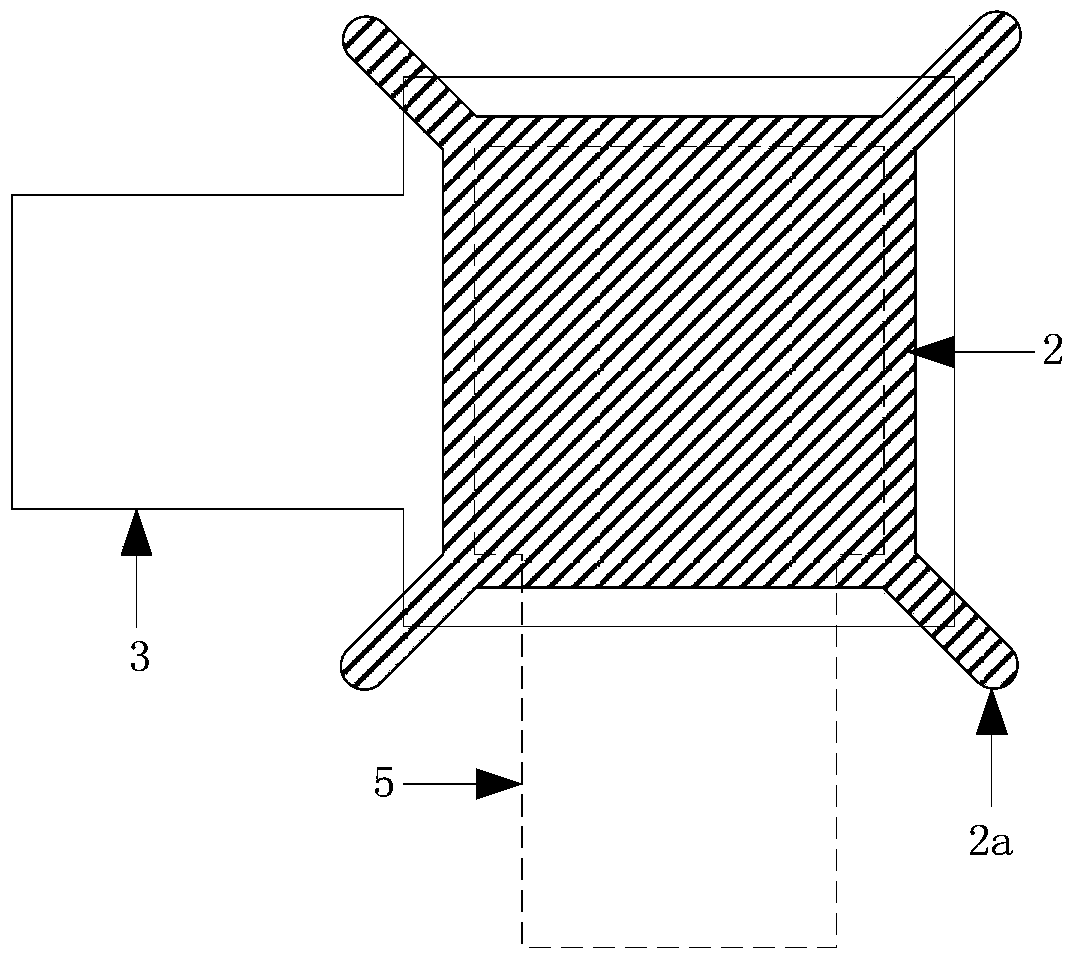

[0058] see figure 2 , which is a schematic cross-sectional view of Embodiment 1 of the FBAR of the present application. On the substrate 1 there is an isolation layer 7 protruding upwards, and the size of the isolation layer 7 is the same as that of the substrate 1 , that is, the isolation layer 7 is on the entire substrate 1 . The substrate 1 is, for example, silicon, sapphire, gallium arsenide, gallium nitride, silicon carbide, quartz, glass and other substrate materials. The isolation layer 7 is, for example, silicon oxide, silicon nitride, silicon oxynitride, aluminum nitride and other materials. There is an air cavity 2 protruding upward from the upper surface of the substrate 1 between the substrate 1 and the raised portion of the isolation layer 7 . On the isolation layer 7 there are respectively the lower electrode 3 , the piezoelectric layer 4 and the upper electrode 5 . The lower electrode 3 and the upper electrode 5 are, for example, metal materials such as alum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com