Method for recirculation of exhaust gas and gas turbine for conducting said method

A gas turbine and recirculation technology, which is applied in gas turbine installations, flue gas combustion, combustion methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

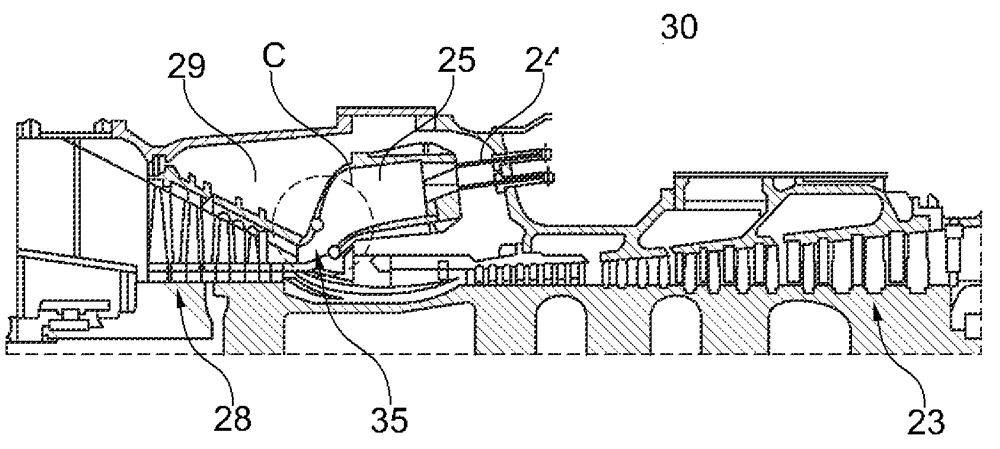

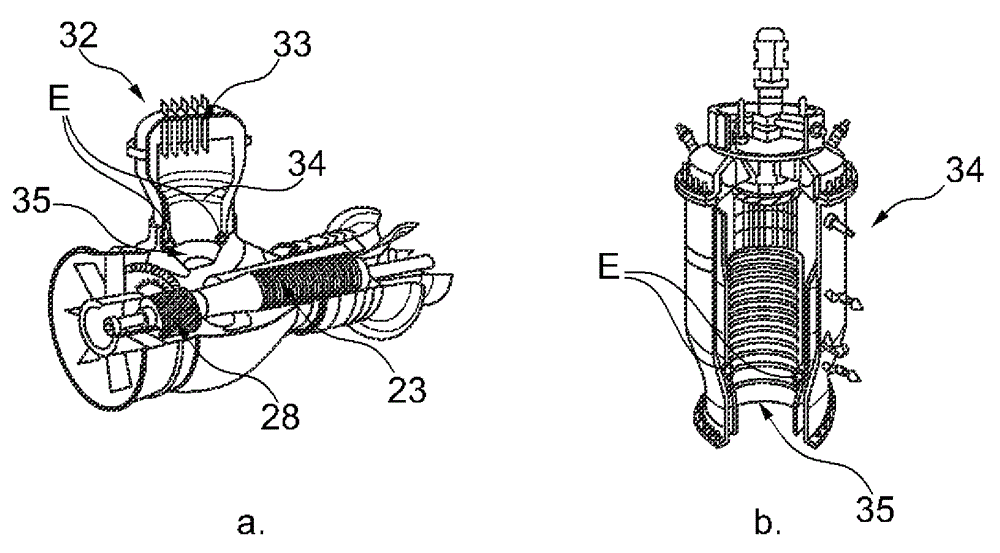

[0068] In the present invention a system is proposed wherein a novel passive flue gas recirculation is proposed. Recirculation is done inside the engine directly at the burner. Such configurations are well suited for sequential annular combustion systems (as in GT24 / GT26, see Figure 5 ), annular combustion (GT13E2, see Figure 6 ), can burner construction (see Figure 7 ) or silo burners (GT11N2, see Figure 8 ).

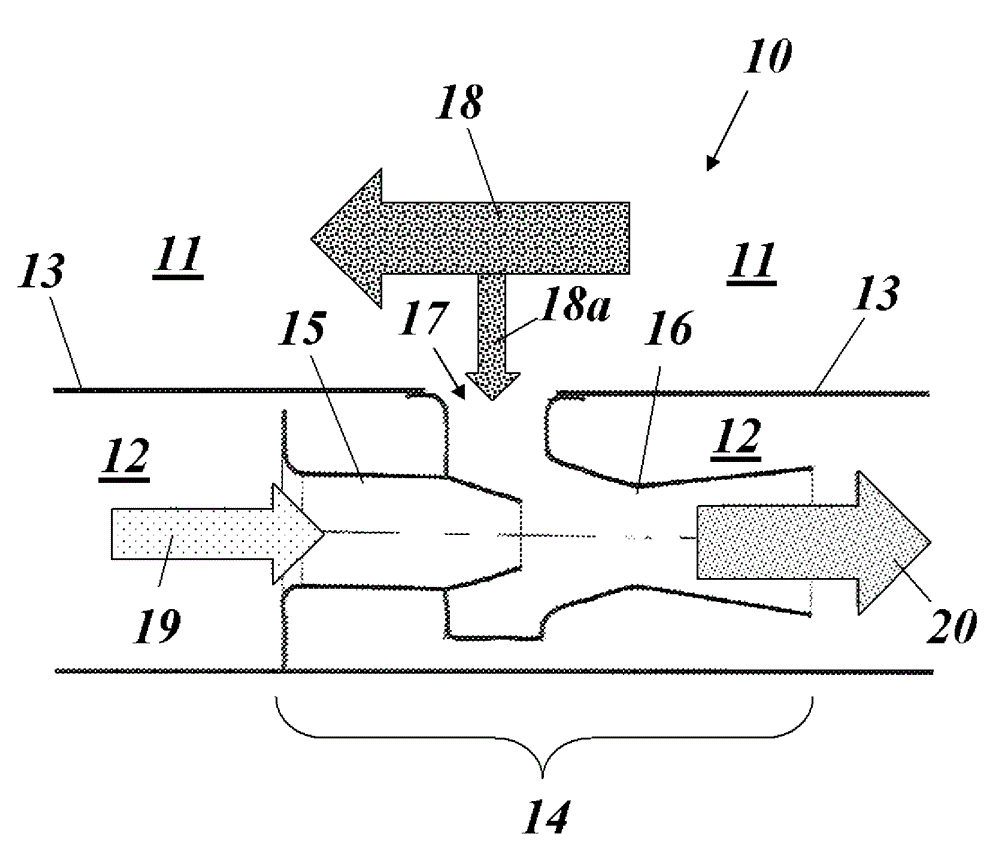

[0069] Systems used to recirculate exhaust gas should be designed to be capable of recirculating 10%-50%. This means that the flue gas (or exhaust) content of the air / flue gas mixture ranges from 10% to 50%.

[0070] Such as figure 2 As shown in FIG. 2 , a combustor liner wall 13 encloses a combustion chamber 11 of a combustor 10 of a gas turbine. Exhaust gas (flue gas) 18 flows from right to left in this example to exit the combustor and enter a subsequent turbine section with rotating blades (not shown). Cooling air channels 12 are arranged on the outsid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com