Rapid and universal positioning clamp and application method thereof

A general positioning and fixture technology, applied in the direction of positioning devices, clamping, clamping devices, etc., can solve the problems of reducing the production cost of enterprises and the management of tooling, the deformation of parts cannot be completely eliminated, and the final delivery quality of parts is affected. Achieve the effects of shortening the production preparation cycle, saving manufacturing costs, reducing clamping fixtures and alignment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

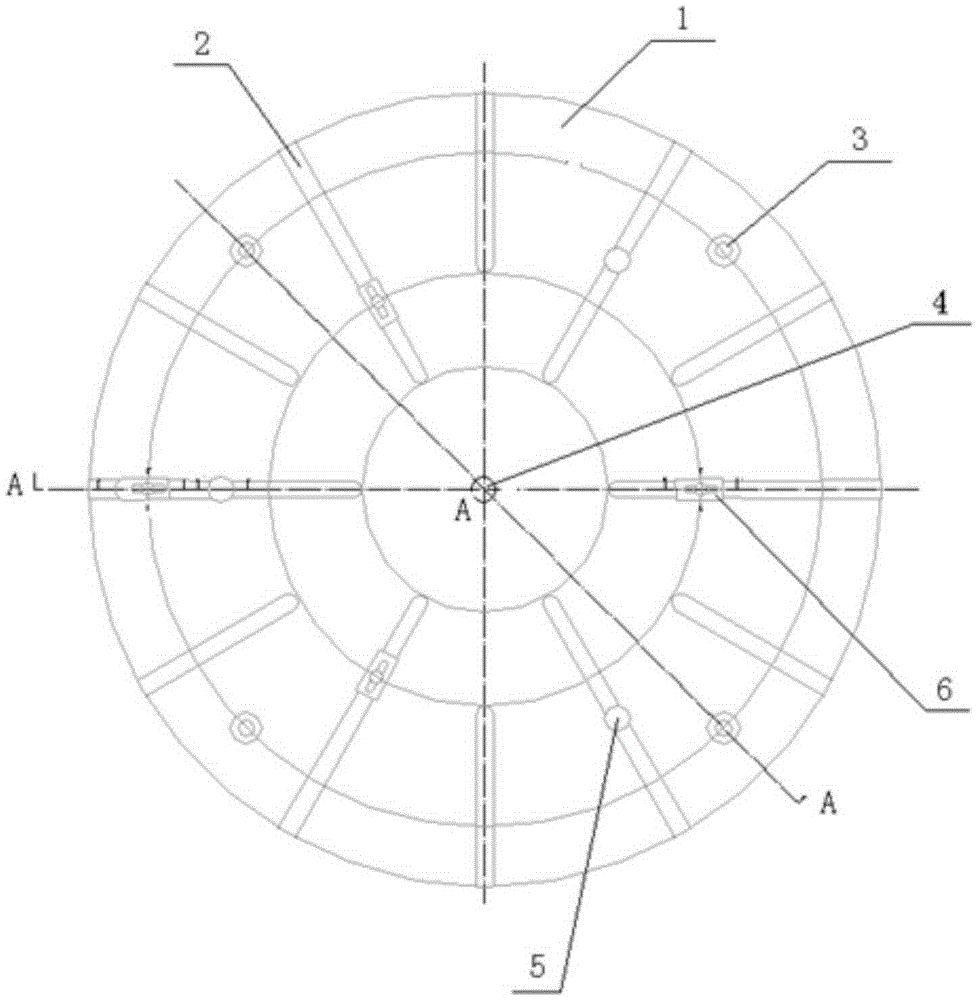

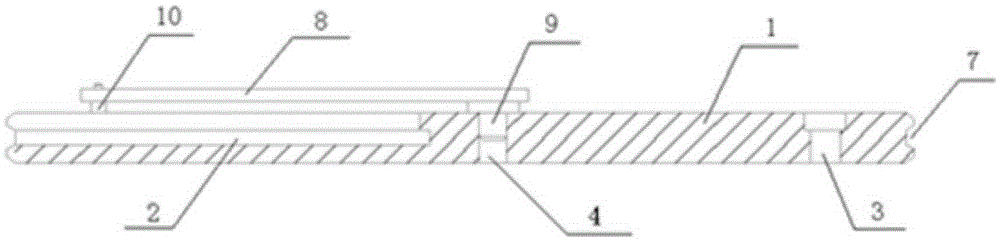

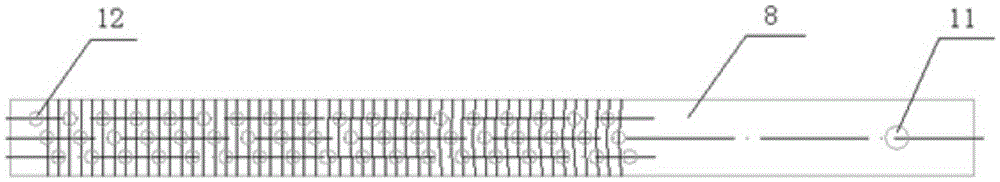

[0029] Such as Figure 1-7 As shown, a fast universal positioning fixture includes a base 1, a T-shaped slider 13, a ball point positioning slider 5, a top block 6, a pressure plate 15, a support block 16, a compression screw 14 and an alignment device. The base is provided with a central hole 4, a T-shaped slot 2, an installation hole 5 and an alignment belt 7, and the number of the installation holes 5 is 4, which are evenly distributed on the base 1; the two ends of the top block 6 are circular arcs shape; the lower part of the ball point positioning slider 5 is a T-shaped block, and the upper part is a spherical body; the alignment device includes an alignment plate 8, a positioning pin 9 and an alignment pin 10, and the alignment plate 8 is provided with positioning hole 11 and a plurality of distance indicating holes 12, the positioning pin 9 is inserted into the positioning hole 11 and the central hole 4, and the alignment pin 10 is inserted into the distance indicating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com