One-hole grouting and filling dual-purpose method implemented by aid of ground gas extraction drill holes

A gas drilling and gas extraction technology, applied in filling, gas discharge, mining equipment, etc., can solve the problem of single project purpose, do not have such problems, prevent movement and deformation, realize the protection of ground buildings, realize the realization of surface The effect of subsidence control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

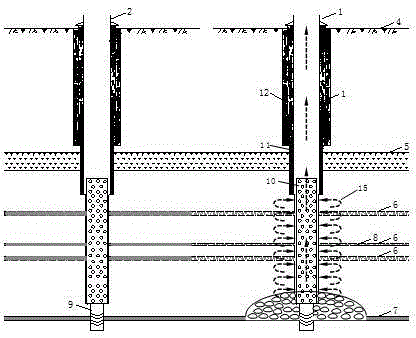

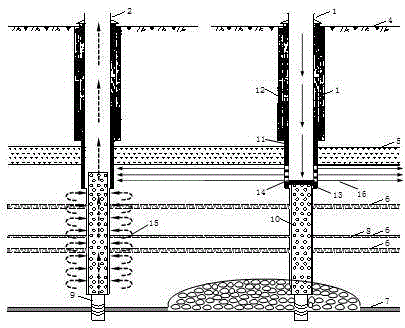

[0016] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings:

[0017] Such as figure 1 As shown, using the ground gas drainage borehole to realize the double-purpose method of grouting filling, using the four-opening hole-forming method to arrange several ground gas boreholes along the working face 3 on the surface 4 above the coal mining face 3. The four-open hole-forming method includes: drilling to form a loose layer cementing section, that is, the first hole, installing the first solid casing 12 in the loose layer cementing section; Drill down until the 10m above the upper adjacent coal seam 6 where the pressurized gas is to be pumped, to form a second opening. The second opening passes through the key layer 5 of the overlying rock of the coal mining face 3. Install the second opening solid casing 11 protective hole in the hole; continue drilling until the 6m above the mining coal seam to form the third opening...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com