Surface drilling pressure relief gas extraction and overlying strata isolated grouting filling synchronous implementing method

A technique for isolating grouting and implementing methods, which is applied in the direction of filling, gas discharge, earthwork drilling, etc., can solve the problems of inability to extract pressure relief gas, failure of grouting filling, communication, etc., and achieve simple method, high efficiency, The effect of overcoming the problem of filling slurry and gas flow interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

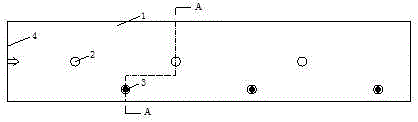

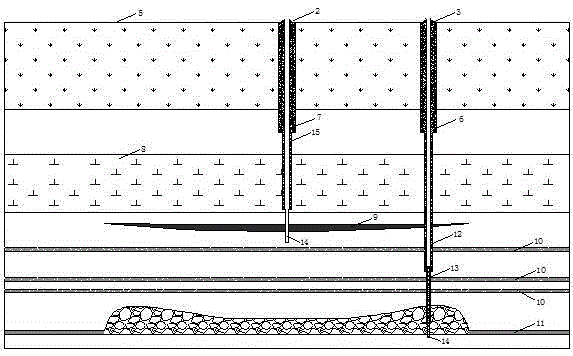

[0016] Such as figure 1 and figure 2 As shown, the method for synchronous implementation of ground drilling pressure relief gas and overlying rock isolation grouting filling of the present invention includes the following steps:

[0017] a. Arrange multiple groups of vertically downward drilling groups on the vertical surface 5 above the coal seam 1 of the coal mining face as required, and the drilling groups include gas drainage drilling 3 and grouting drilling 2, wherein the grouting The borehole 2 is located in the middle of the coal mining face 1, and the gas drainage borehole 3 advances the grouting borehole 2 along the strike direction; the grouting borehole 2 is formed by 3 holes, and the first borehole is the loose layer cementing section , the first solid casing 7 is installed in the loose layer cementing section, the bottom of the second hole is located above the bottom interface of the main key layer 8, and the second solid casing 15 is installed to protect the ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com