Hydraulic cylinder internal leakage test device and method

A test method and hydraulic cylinder technology, which is applied in the direction of fluid pressure actuation device, fluid pressure actuation system test, mechanical equipment, etc., can solve the problems such as the inability to measure the leakage of the piston, and achieve accurate and effective measurement results, precise measurement, and measurement The results are accurate and reliable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

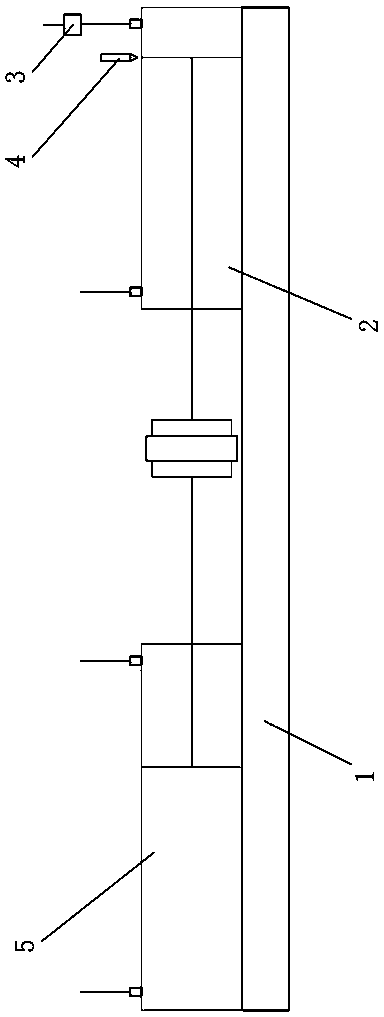

[0023] figure 1 It shows an embodiment of a hydraulic cylinder internal leakage testing device of the present invention, the device includes a base 1 and a loading hydraulic cylinder 2 for loading the hydraulic cylinder 5 to be tested, the loading hydraulic cylinder 2 is installed on the base 1, The loading hydraulic cylinder 2 is connected with an oil return overflow valve 3 , and the loading hydraulic cylinder 2 is equipped with a displacement sensor 4 for measuring the displacement of the piston of the loading hydraulic cylinder 2 .

[0024] The leakage test device in the hydraulic cylinder of the present invention can stop the piston of the hydraulic cylinder 5 to be tested at any position in the cylinder body by loading the hydraulic cylinder 2 and the oil return overflow valve 3. During the measurement, the hydraulic cylinder 2 is loaded The internal leakage of itself will cause the pistons of the loading hydraulic cylinder 2 and the hydraulic cylinder 5 to be tested to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com