Method for measuring wettability of lithium battery electrolyte or lithium ion battery electrolyte on battery material

A lithium-ion battery and electrolyte technology, which is applied to the accurate measurement of the wettability of the negative electrode and diaphragm, and the field of measuring the electrolyte to the positive electrode of the battery. It can solve the problem of not clearly describing the specific steps of the test, the contact angle test conditions and parameters, and the inability to simulate electrolysis. Eliminate the problems of liquid infiltration process on the positive and negative electrodes, low accuracy, etc., to achieve the effect of optimizing the static process of the battery, accurate and reliable measurement results, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] LiFePO 4 Preparation of positive electrode substrate: active material LiFePO 4 The content of carbon black is 95%, carbon black is 3.0%, and binder PVDF2.0% is evenly mixed, and the prepared slurry is evenly coated on the aluminum current collector, flattened and sliced on a double-roller machine, and the flat pole piece will be prepared Vacuum-dried at 110° C. for 14 hours to obtain the substrate to be tested.

[0032] The electrolyte to be tested is: ethylene carbonate 26.4%, diethyl carbonate 24.2%, propylene carbonate 35.9%, LiPF 6 12.5%, vinylene carbonate 1%.

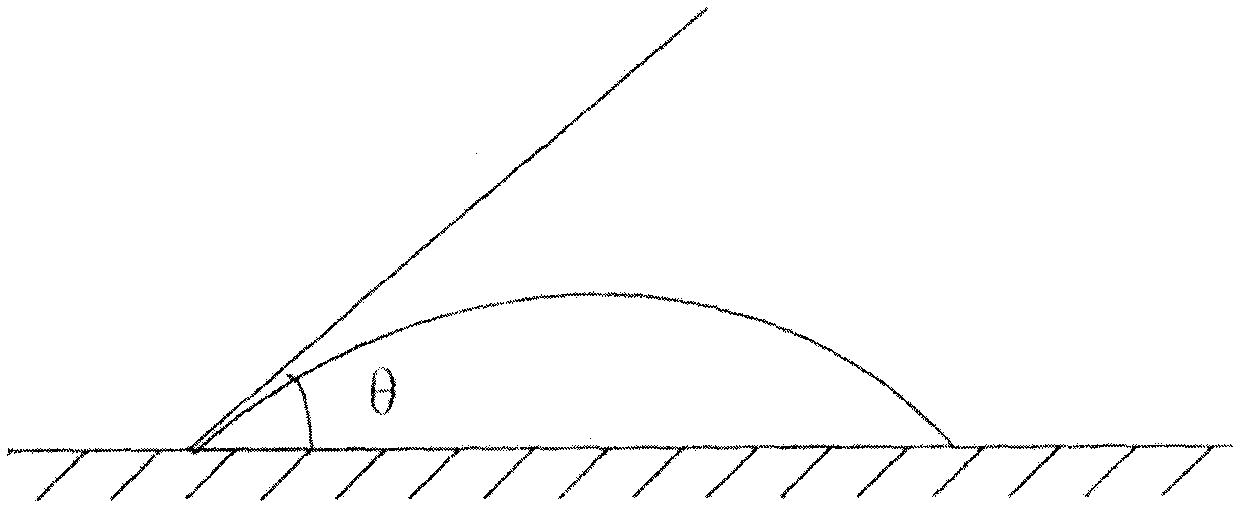

[0033] Wettability measurement: Place the positive electrode substrate flat on the platform, drop 5 μL of liquid droplets with a micro-sampler at 25°C, the height of the droplet falling and the test substrate is 0.2cm, and set the shooting speed of the contact angle measuring instrument to 40 frames / s, continuous shooting, with a magnification of 30 times, and analyze the photos taken of the droplet f...

Embodiment 2

[0036] The test substrate of the tested electrolyte is: polypropylene diaphragm.

[0037] The electrolyte to be tested is: 26% ethylene carbonate, 24% diethyl carbonate, 20% ethyl methyl carbonate, 14% ethyl acetate, LiPF 6 15%, vinylene carbonate 1%.

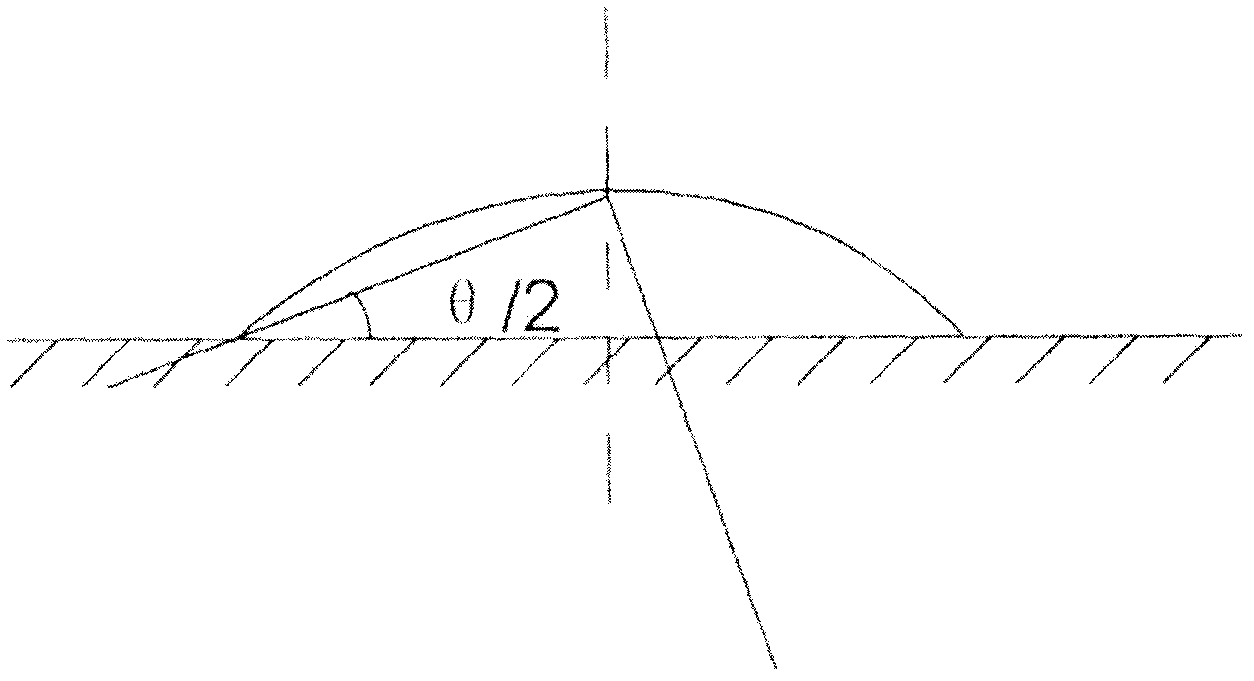

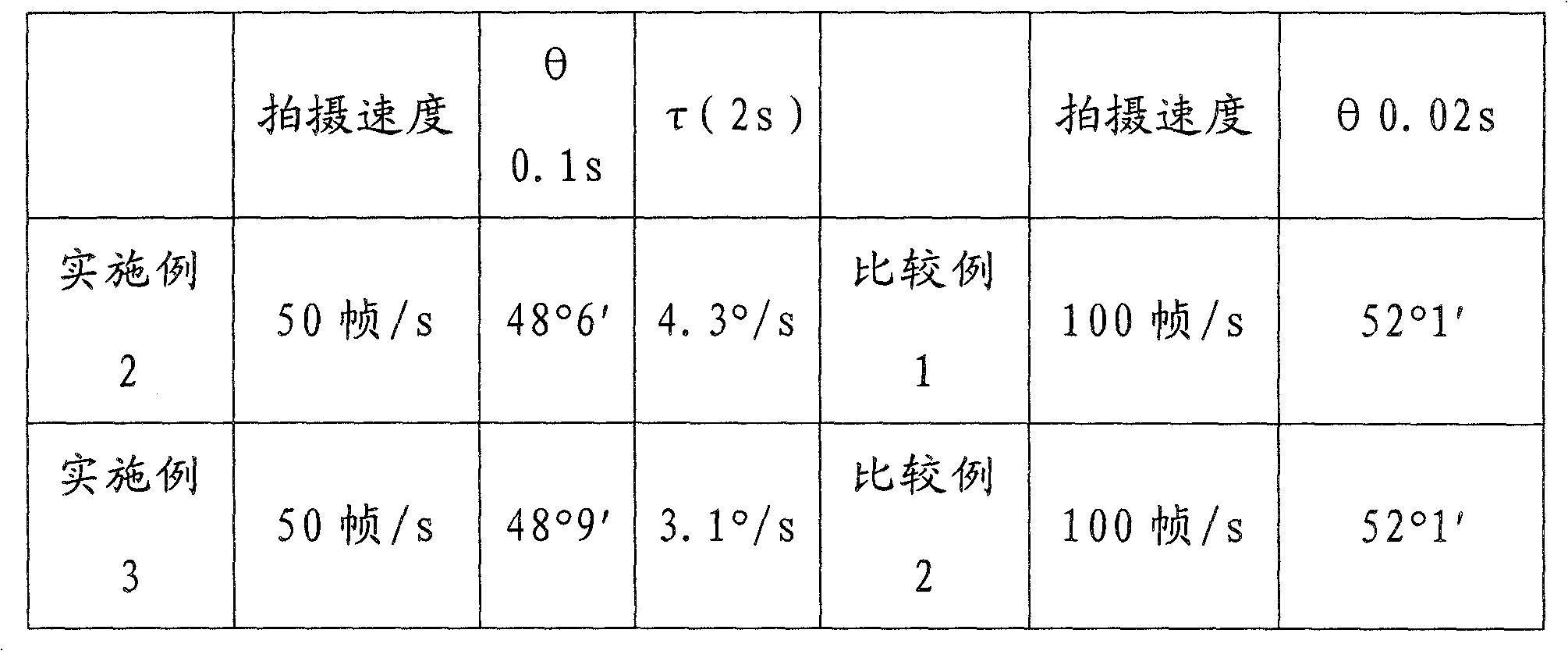

[0038] The measurement method is as the measurement of wettability in Example 1. The diaphragm is placed flat on the platform. At 25°C, a 7 μL droplet is dropped with a micro-sampler. The height between the droplet and the test substrate is 0.2cm. Set the shooting speed to 50 frames / s, shoot continuously, and the magnification factor is 30 times. Analyze the photos of the falling droplets and use the half-angle method for analysis. The θ1 when recording 0.05s is 49°4′, greater than 20 °, the shooting speed remains unchanged, 0.1s of θ0.1s is 48°6′; θ0 is 51°7′, θ2s is 43°2′, and the infiltration speed τ in the first 2s is calculated according to the formula to be 4.3° / s.

Embodiment 3

[0040] The test substrate and determination method are the same as in Example 2, only the electrolyte is different from Example 2.

[0041] The electrolyte to be tested is: 26% ethylene carbonate, 24% diethyl carbonate, 20% ethyl methyl carbonate, 14% ethyl propionate, LiPF 6 15%, vinylene carbonate 1%.

[0042] The wettability result obtained is that θ1 at 0.05s is 51°4′, using the shooting speed parameters of Example 2, θ0.1s at 0.1s is 48°9′, θ0s is 51°3′, and θ2s is 45°2′ , according to the formula, the infiltration velocity τ in the first 2s is 3.1° / s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com