Method for evaluating functional safety of safety instrument system

A safety instrumented system and functional safety technology, which is applied in the field of functional safety assessment of safety instrumented systems, can solve problems such as unacceptable risk and cost waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to make the purpose, content, and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

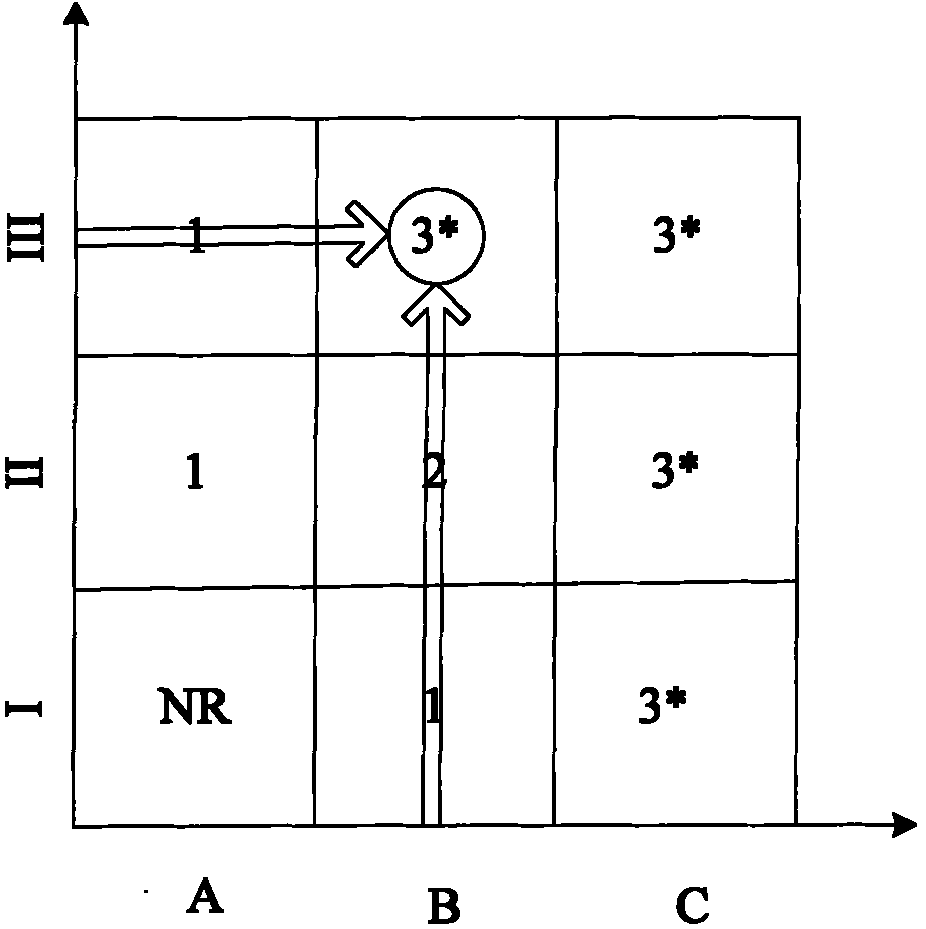

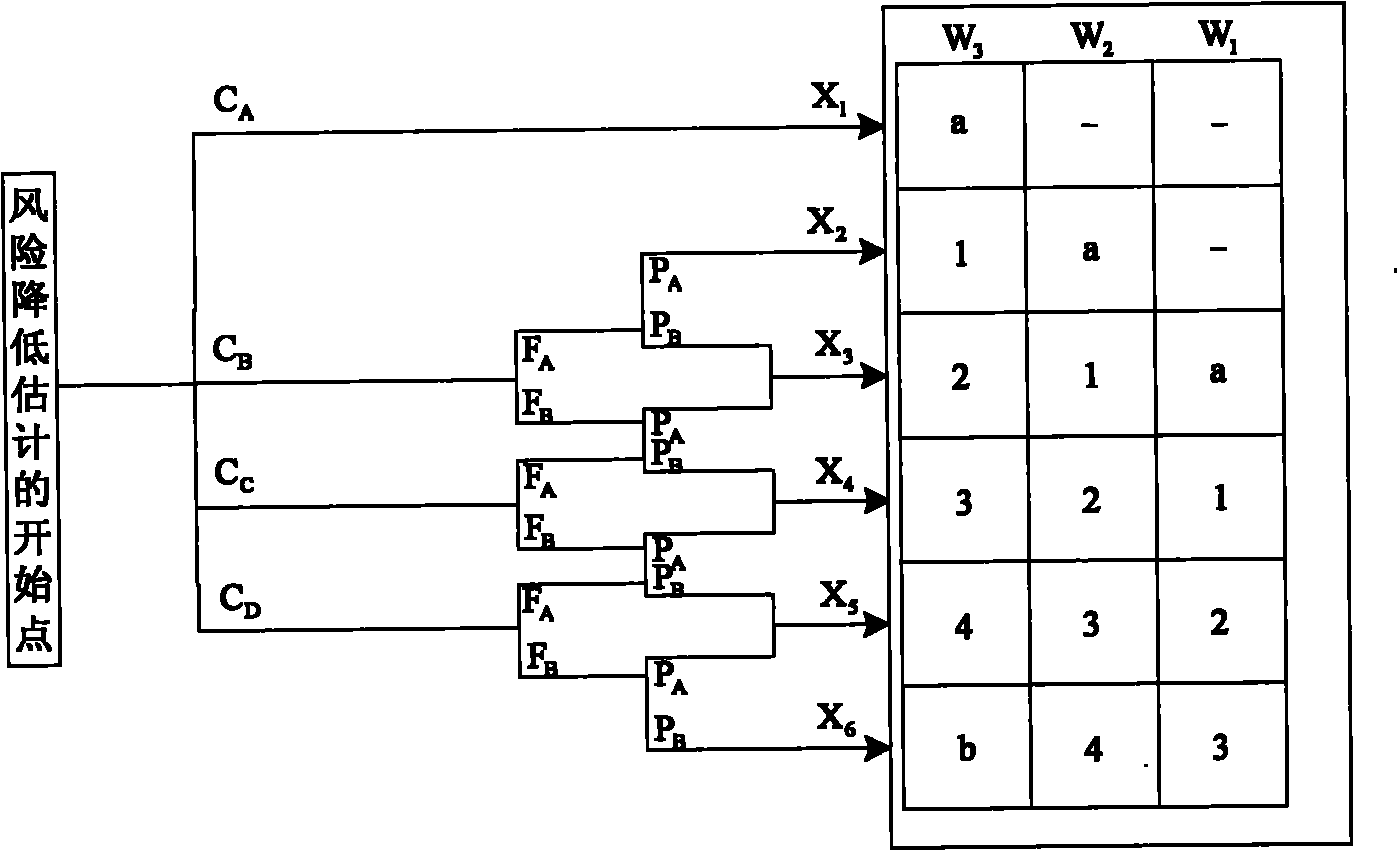

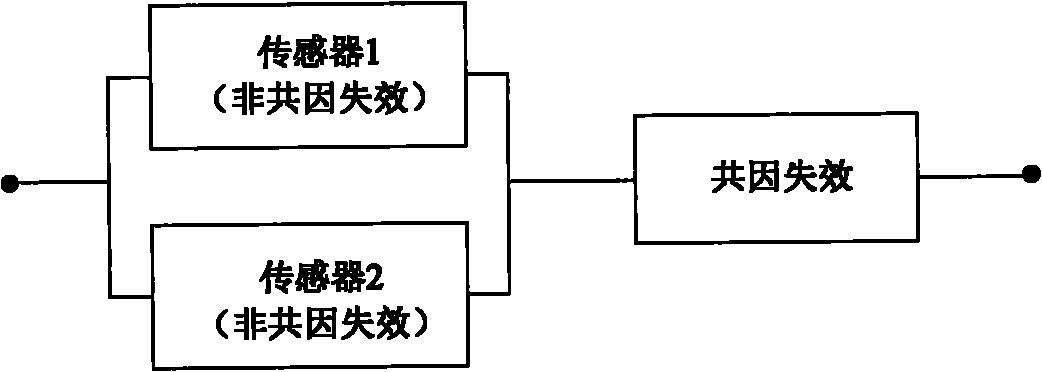

[0041] like image 3 As shown, regarding the safety instrumented system functional safety assessment method provided by the present invention, it includes:

[0042] S1: The safety instrumented system performs functional safety control on the controlled system;

[0043] This step specifically includes the following steps:

[0044] S101: Pre-set the critical value of the state parameter when the controlled system is in normal operation according to the external command input by the human-computer interaction device;

[0045] S102: Obtain the current state parameters of the controlled system through the sensor unit, and use the simulation unit to simulate the current state and the overload state of the controlled system...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com