Turbine flow curve identification and optimization method based on feature flow area

A technology of flow area and optimization method, applied in mechanical equipment, engine components, machines/engines, etc., can solve problems such as insufficient response load, excessive load, and fluctuation of valve switching load.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

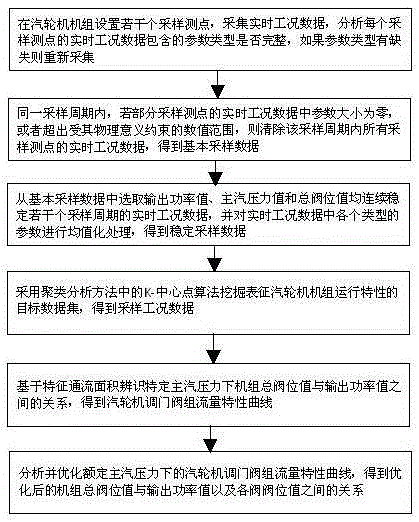

[0027] Such as figure 1 As shown, the steam turbine flow curve identification and optimization method based on the characteristic flow area of the present invention comprises the following steps:

[0028] A. Set several sampling measuring points in the steam turbine unit, and set the sampling cycle and sampling time, collect the real-time working condition data of the steam turbine unit, and analyze whether the parameter types contained in the real-time working condition data of each sampling measuring point are complete. If the parameters If the type is missing, it will be collected again. If the parameter type is not missing, go to step B.

[0029] B. For all sampling points, if within the same sampling period, the real-time working condition data of one or more sampling measuring points has a parameter size of zero, that is, there is a blank working condition data, or the parameter size exceeds the constraints of its physical meaning In other words, when there is abnorma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com