Pipe-in-pipe buckle arrestor based on C and W type section deformation elements

A technology of deforming element and pipe-in-pipe, which is applied in pipeline laying and maintenance, pipe/pipe joint/pipe fitting, mechanical equipment, etc. Thermal insulation performance, efficient laying, and the effect of preventing relatively large movements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

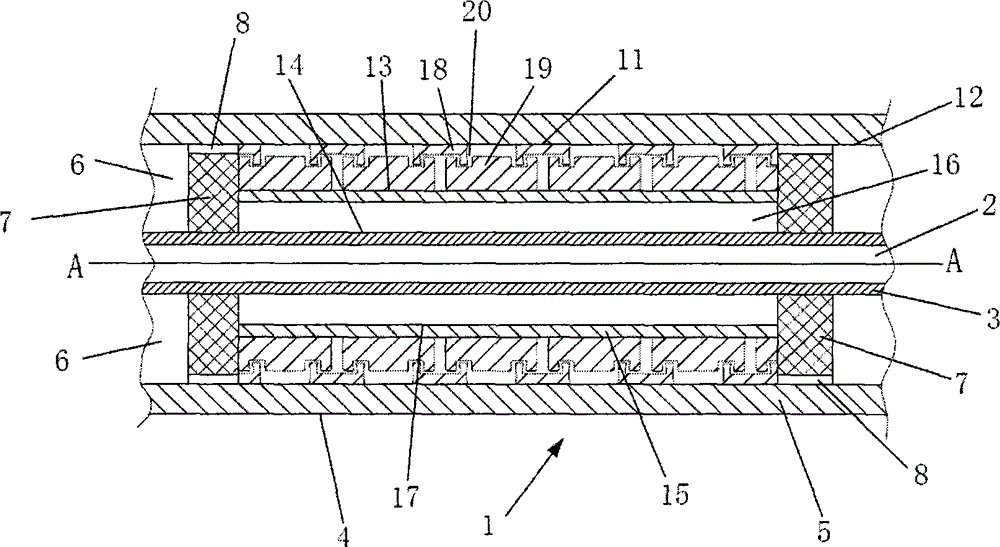

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

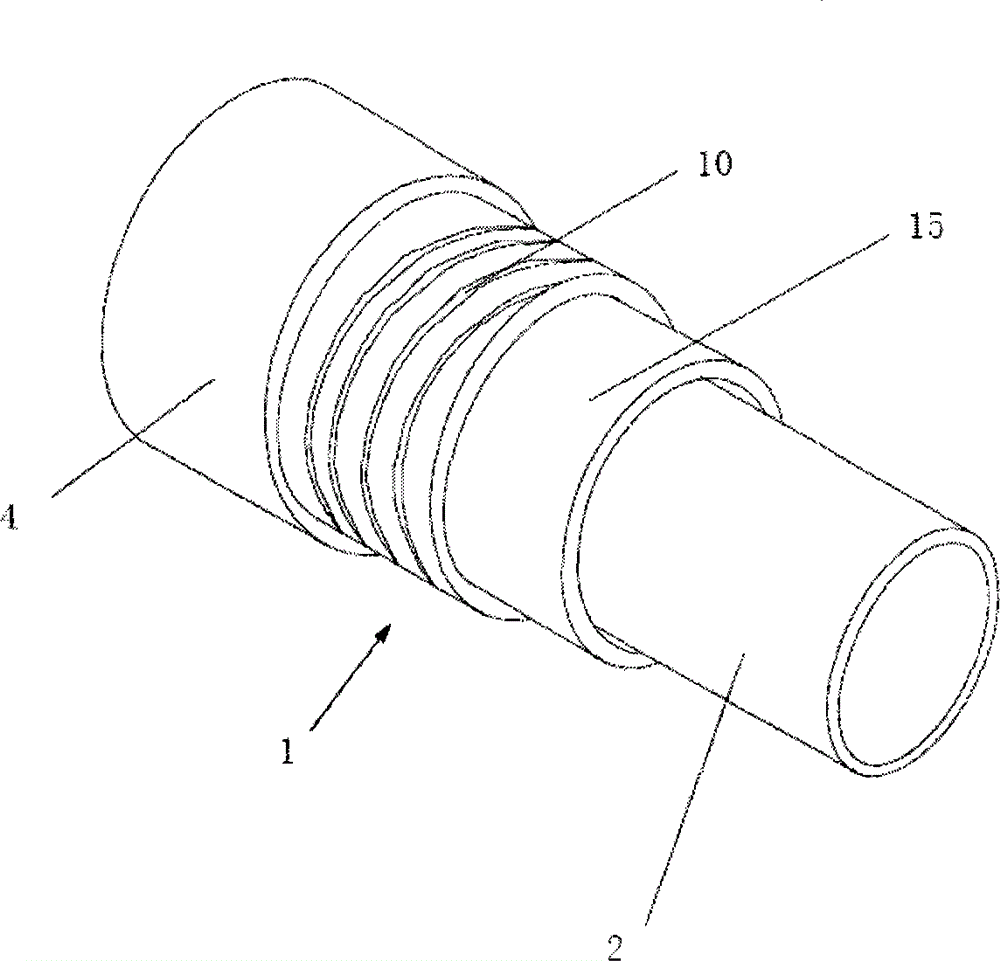

[0025] according to figure 1 and figure 2 As shown, in the present invention, the central axis of the rigid tube 1 is AA, and the rigid tube 1 is a tube-in-tube type, consisting of an inner tube 2 and an outer tube 4 . The pipe wall 3 of the inner pipe 2, the diameter and the material of the inner pipe 2 are determined according to the specific requirements of use.

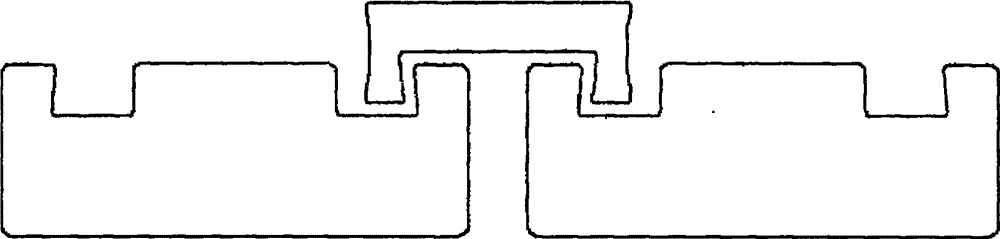

[0026] The diameter of the outer tube 4 is large enough to allow the inner tube 2 to be inserted into it. The tube wall 5 of the outer tube 4 is sufficient to bear the pressure of the medium outside and around the rigid tube. There is an annular area 6 between the inner pipe 2 and the outer pipe 4, which is an annular area about several centimeters from the outer surface of the inner pipe 2 to the inner surface of the outer pipe 4 in the diameter direction. In the above-mentioned dou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com