A buckle arrester for pipe in deep water pipe based on t-section deformation element

A deformation element and tube-in-tube technology, which is used in pipeline protection, pipeline laying and maintenance, and protection of pipelines through thermal insulation, etc. The effect of thermal insulation performance, efficient laying, and convenient storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

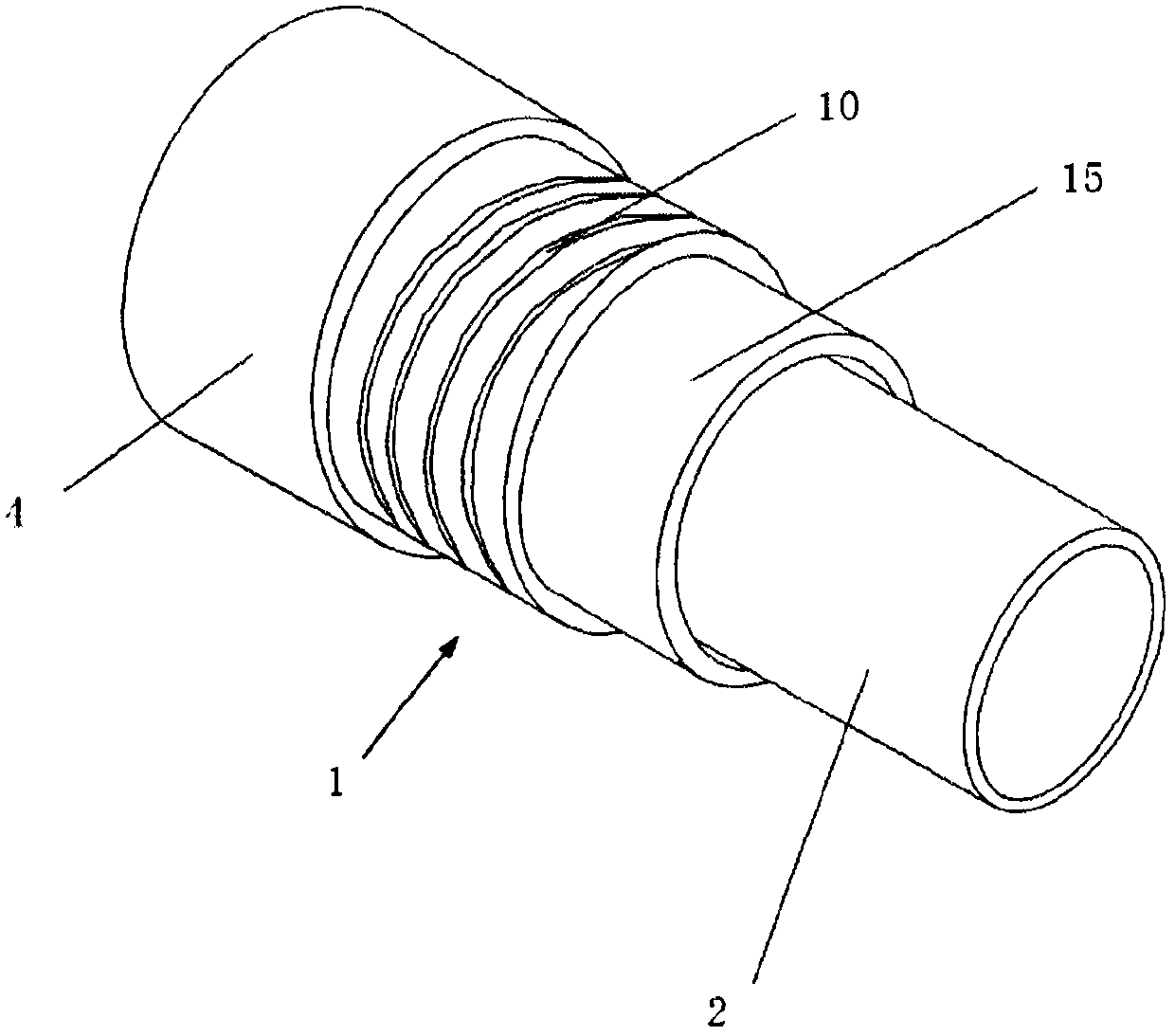

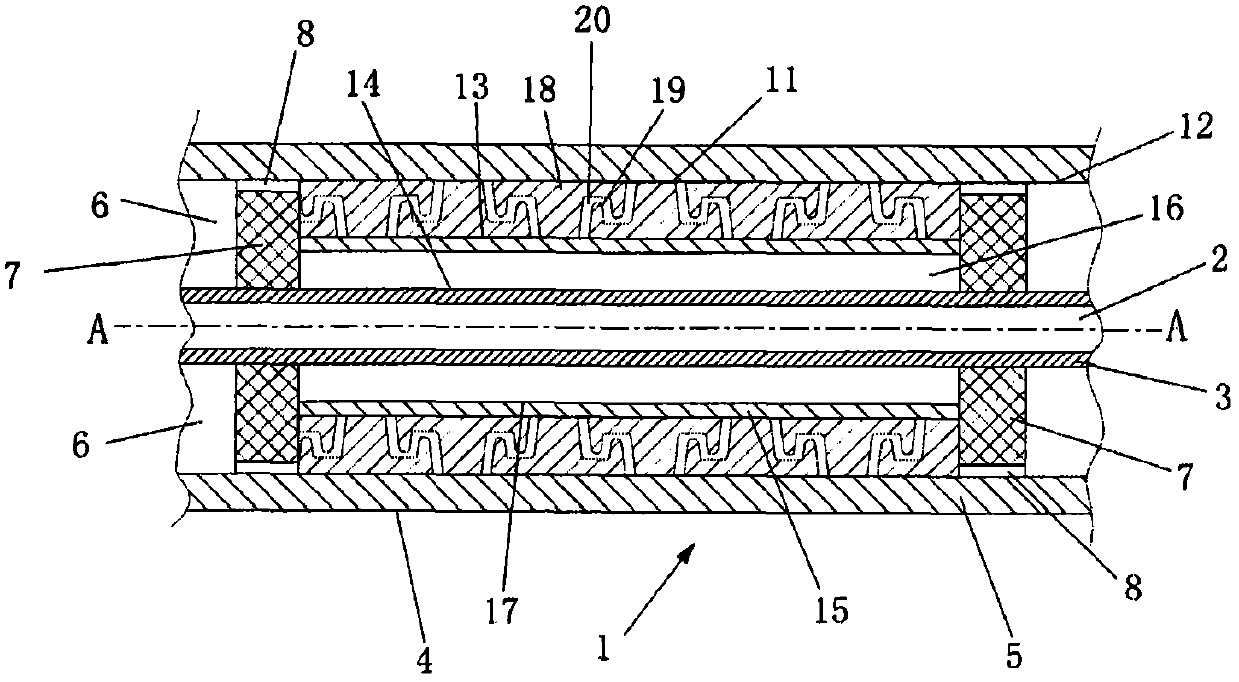

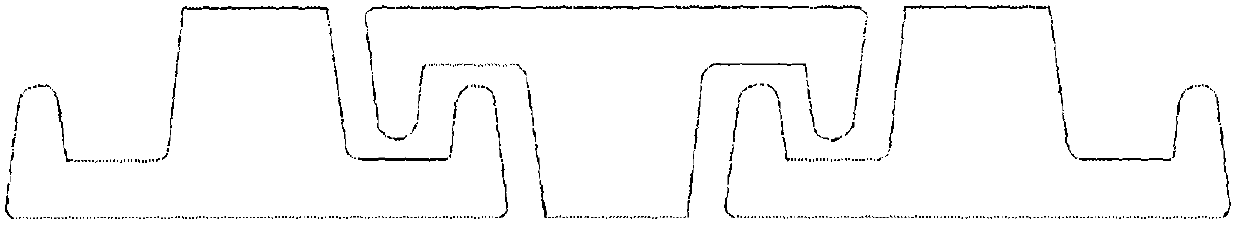

[0024] according to Figure 1 and Figure II As shown, in the present invention, the central axis of the rigid tube 1 is AA, and the rigid tube 1 is a tube-in-tube type, consisting of an inner tube 2 and an outer tube 4 . The wall thickness 3 of the inner pipe 2, the diameter and the material of the inner pipe 2 are determined according to the specific requirements of use.

[0025] The diameter of the outer tube 4 is large enough to allow the inner tube 2 to be inserted into it. The wall thickness 5 of the outer tube 4 is sufficient to bear the pressure outside and around the medium in which the rigid tube is located. There is an annular area 6 between the inner pipe 2 and the outer pipe 4, which is an annular area about several centimeters from the outer surface of the inner pipe 2 to the inner surface of the outer pipe 4 in the diameter direction....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com